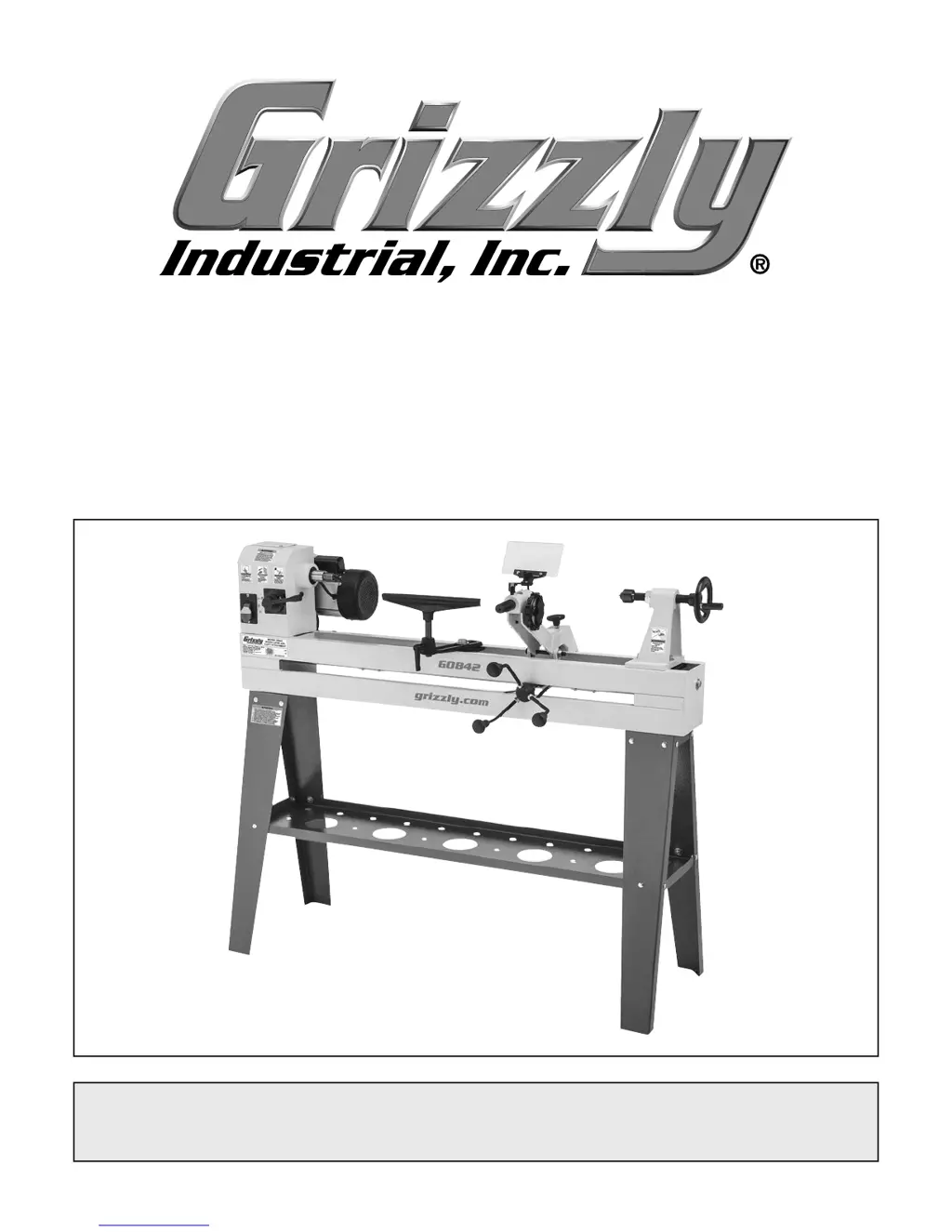

Why does my Grizzly Lathe power-supply fuse keep tripping?

- AAshley BrownNov 2, 2025

Your Grizzly Lathe's fuse might be tripping due to several reasons: * The switch disabling key might be removed; install it. * The power supply voltage or circuit size could be incorrect; ensure they are correct. * The circuit breaker might be tripped, or the fuse blown; reset the breaker or replace the fuse, ensuring the circuit is correctly sized and free of shorts. * Motor or power cord wires might be disconnected, damaged, or incorrectly connected; fix or replace them. * Wiring might be open or have high resistance; check and fix broken, disconnected, or corroded wires. * The ON/OFF switch could be faulty; replace it. * The start capacitor might be faulty; test or replace it. * The centrifugal switch might be faulty; adjust or replace it if available. * The motor its...