How to shift gear change levers on Grizzly Lathe?

- SSandra Anderson MDSep 3, 2025

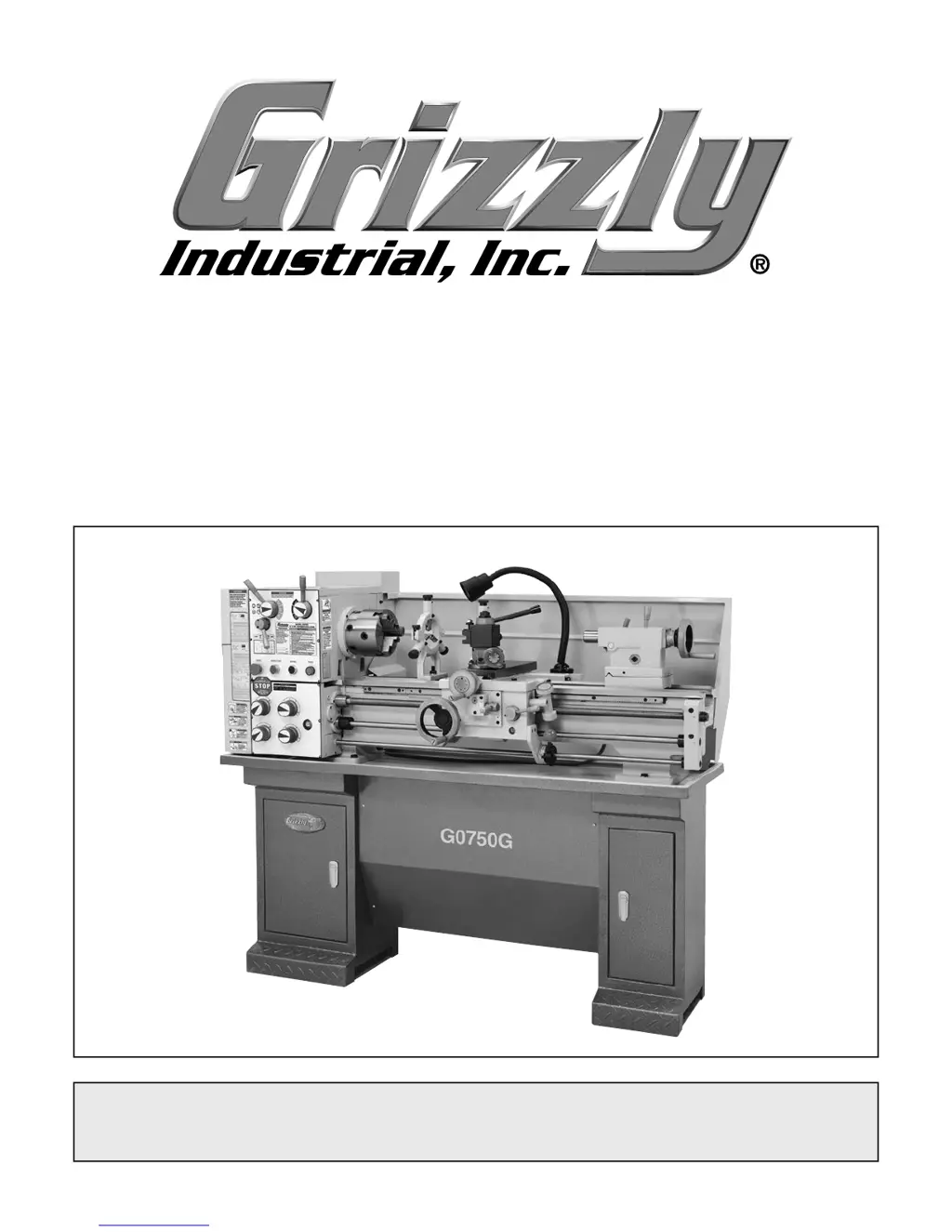

If the gear change levers on your Grizzly Lathe won't shift into position, rotate the spindle by hand while applying light pressure on the lever until the gear falls into place.