-76-

Model G0750G (Mfg. Since 11/12)

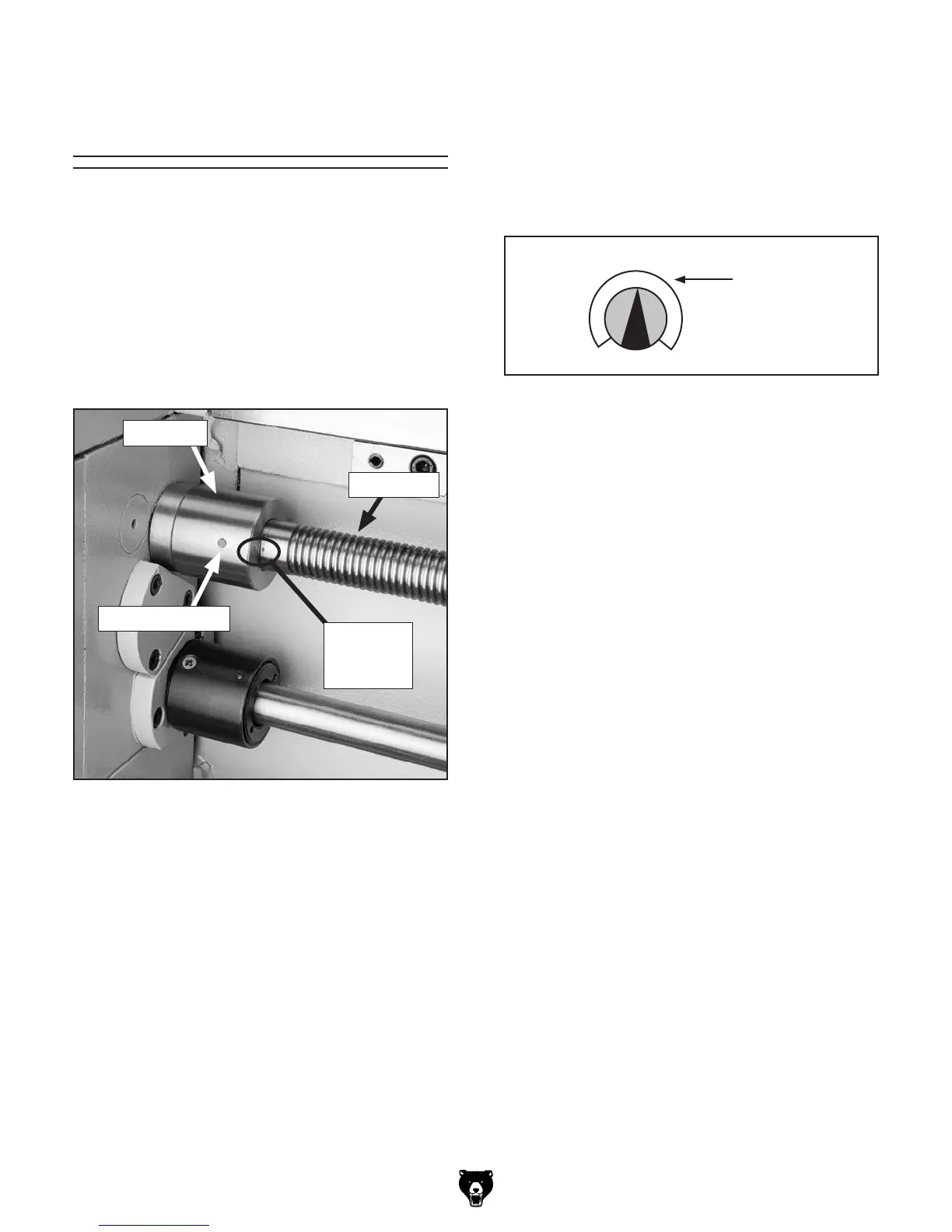

A straight 4 x 42mm brass shear pin (see Figure

130) holds the leadscrew and the drive hub

together. The pin is designed to break and disen-

gage the power transfer to the leadscrew to help

protect more expensive lathe components in the

case of a carriage crash or the lathe is overloaded.

Contact Grizzly Customer Service at (570) 546-

9663 to order a replacement shear pin (Part

P0750G0960).

To replace the leadscrew shear pin:

1. DISCONNECT LATHE FROM POWER!

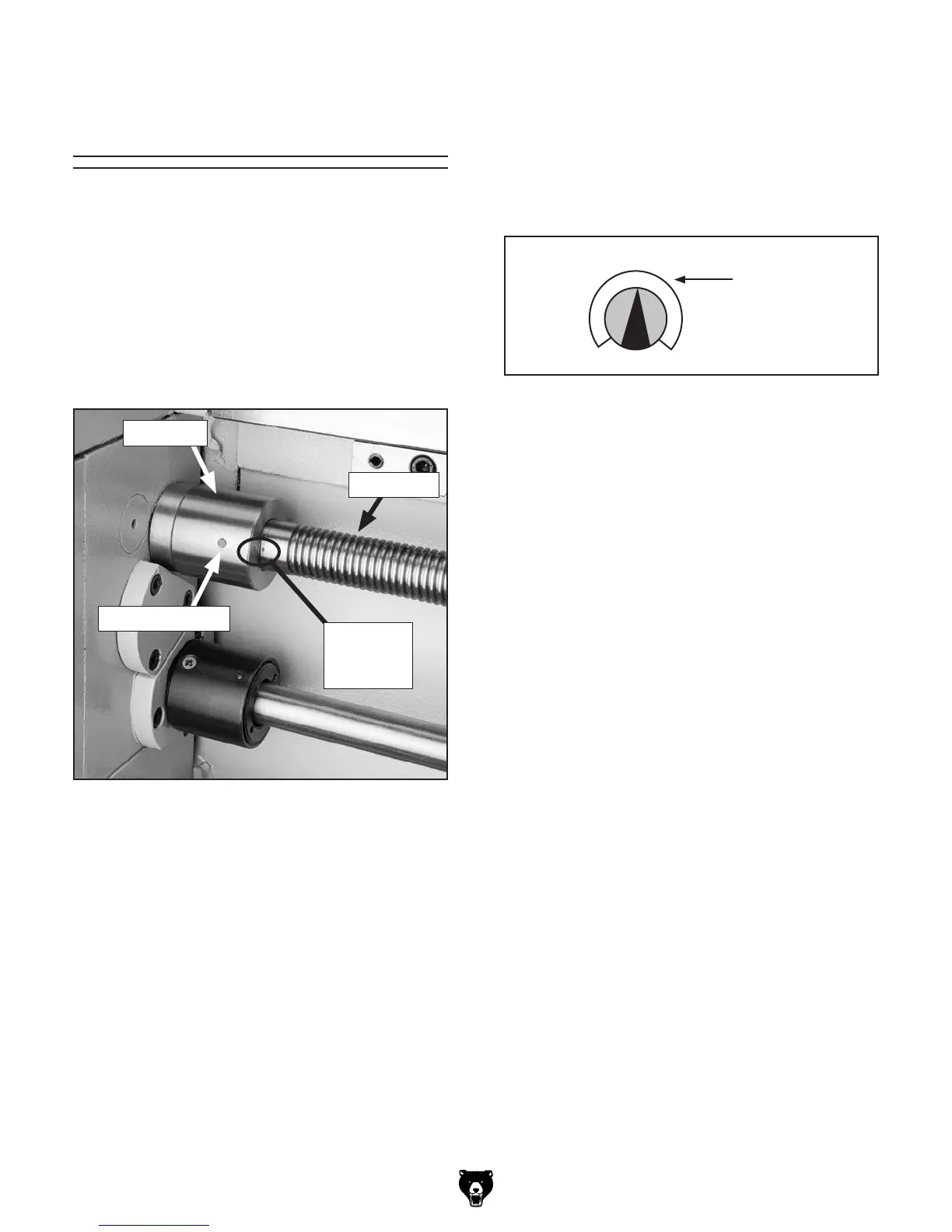

2. Unlock the half-nut lever and turn the top right

gearbox dial to "N" (see Figure 131) so the

leadscrew can be rotated by hand.

Figure 130. Leadscrew shear pin.

Tools Needed Qty

Hammer ............................................................. 1

Dowel Punch

3

⁄16" ............................................... 1

Drill Bit

1

⁄8" ......................................................... 1

Hand Drill .......................................................... 1

Wood Screw #8 x 1" (or longer) ........................ 1

Pointed Center Punch ....................................... 1

Standard Pliers .................................................. 1

Optional

Alignment

Marks

Brass Shear Pin

Drive Hub

Leadscrew

Leadscrew Shear Pin

Replacement

Pointer Set to "N"

1

2 3

N

4

Figure 131. Gearbox dial set to "N" .

3. Rotate the drive hub, and inspect it to see if

the pin is still stuck in both sides of it.

—If one half of the shear pin has fallen out

and the leadscrew shaft can be seen

through the pin hole, rotate the leadscrew

until you see the end of the inner sheared

pin. Use a

3

⁄16" dowel punch to tap the pin-

out through the other side.

—If the shear pin halves are stuck in both

sides of the drive hub, center punch one

of the pins and drill an

1

⁄8" hole in the pin

approximately

1

⁄4" deep. Thread a #8 wood

screw into the hole until the screw begins

to thread into the brass. Using pliers, pull

the pin from the hole, then drive the rest of

the pin out, as desribed above.

4. Align the holes in the drive hub with the hole

in the leadscrew, and tap the new shear pin

into position until it is flush.

Tip: For easy shear pin replacement in the

future, use the center punch or a scribe and

mark the end of the drive hub and the side of

the leadscrew with a timing mark to indicate

where true hole alignment is located. Next,

scribe a line on the leadscrew just where it

enters the drive hub, this line will indicate cor-

rect depth of leadscrew. Should the pin ever

shear again, line-up the marks, and drive out

the pin pieces, and tap in the new pin.

Loading...

Loading...