Model G0750G (Mfg. Since 11/12)

-75-

After initial break in, the V-belts slightly stretch

and seat into the pulley. It is important to check

and adjust them to compensate for this initial

wear. Check the tension thereafter on a monthly

basis. If the belts become excessively worn or

damaged, replace them as a matched set.

Tools Needed Qty

Hex Wrench 17mm ............................................ 1

Tensioning V-Belts

1. DISCONNECT LATHE FROM POWER!

2. Remove the end gear cover.

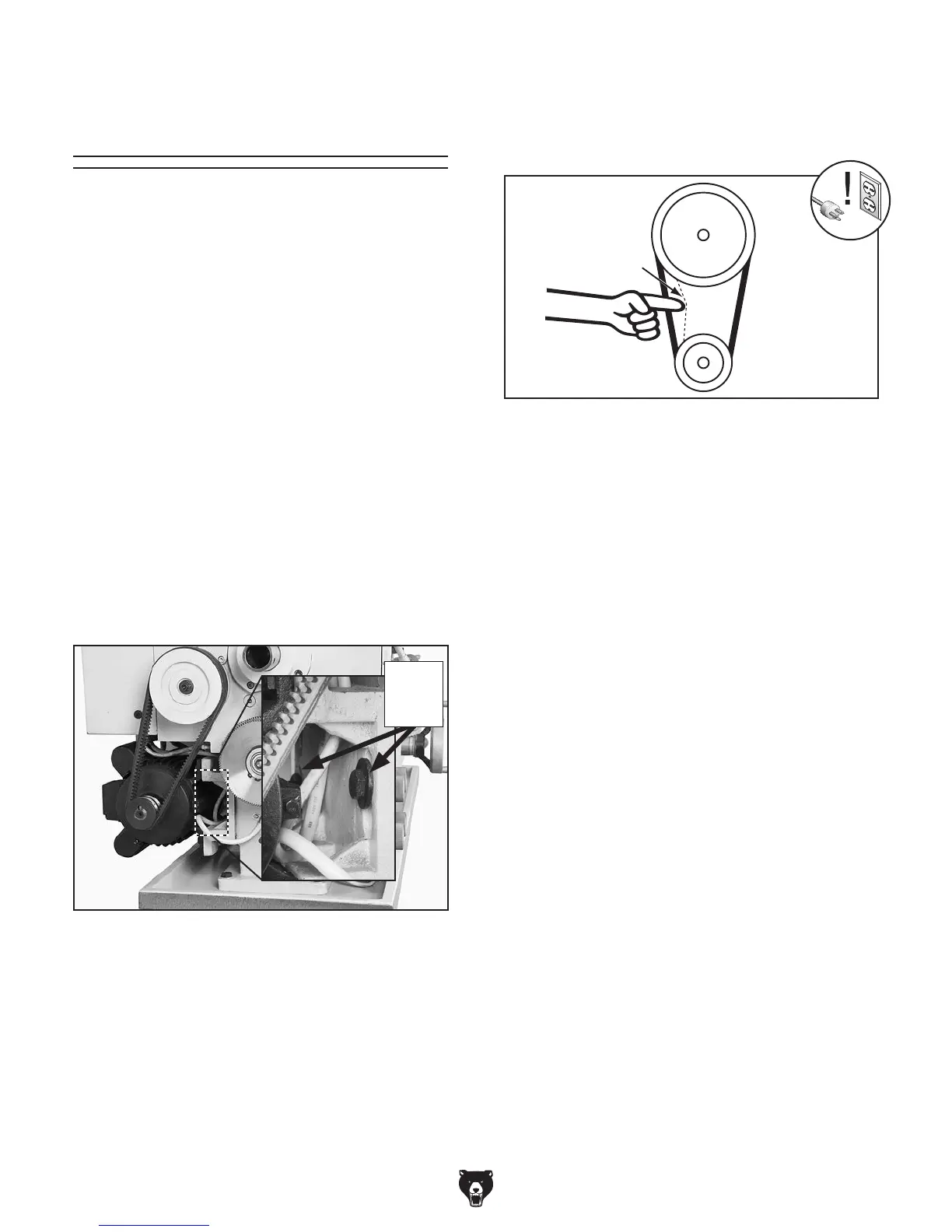

3. Loosen the motor mount hex bolts (see

Figure 128).

Note: It may be more convenient to access

the motor mount hex nuts if you first remove

the rear splash guard.

Figure 128. Checking V-belt deflection.

V-Belt Tension &

Replacement

4. Push down on the motor and re-tighten the

mounting hex bolts.

—If there is more than

1

⁄4" deflection when

each belt is pushed with moderate pres-

sure, loosen the motor mount bolts, lower

the motor, adjust belt tension as required,

then tighten the bolts.

6. Secure the end gear cover.

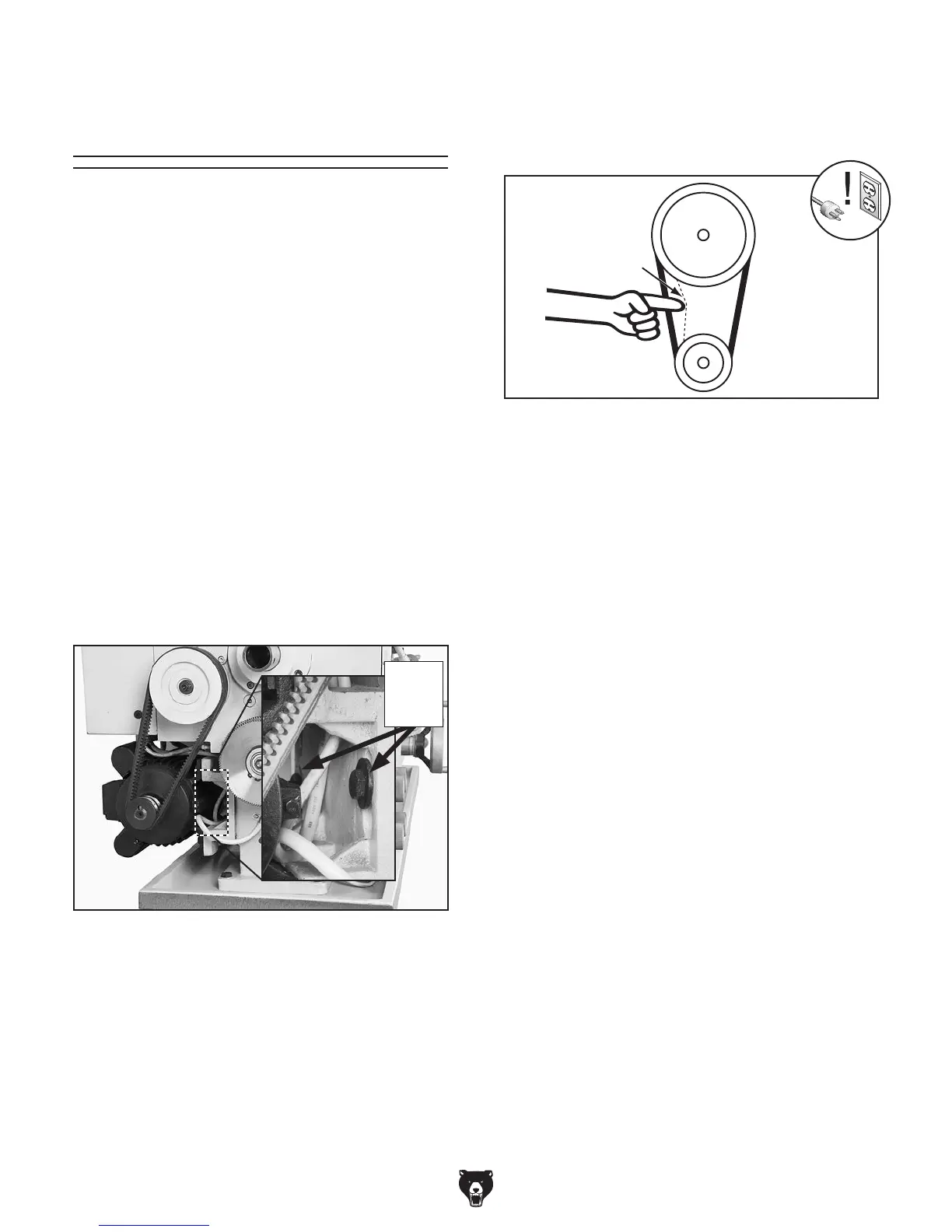

Pulley

Deflection

Pulley

Figure 129. Correct timing-belt deflection.

1

⁄4"

Replacing V-Belts

1. DISCONNECT LATHE FROM POWER!

2. Remove the end gear cover.

3. Loosen the motor mount bolts (see Figure

128), slide the motor up, and remove the

V-belts.

Note: It may be more convenient to access

the motor mount bolts if you first remove the

rear splash guard.

4. Install the new V-belts as a matched set so

they equally share the load.

5. Tension the belts. (Refer to Tensioning

V-Belts on this page.)

6. Secure the end gear cover.

Motor

Mount

Bolts

5. Check the belt tension: Each belt is correctly

tensioned when there is approximately

1

⁄4"

deflection when it is pushed with moderate

pressure, as shown in Figure 129.

Loading...

Loading...