Model G0750G (Mfg. Since 11/12)

-53-

The following subsections will describe how to

use the threading controls and charts to set up the

lathe for a threading operation. If you are unfamil-

iar with the process of cutting threads on a lathe,

we strongly recommend that you read books,

review industry trade magazines, or get formal

training before attempting any threading projects.

Headstock Threading Controls

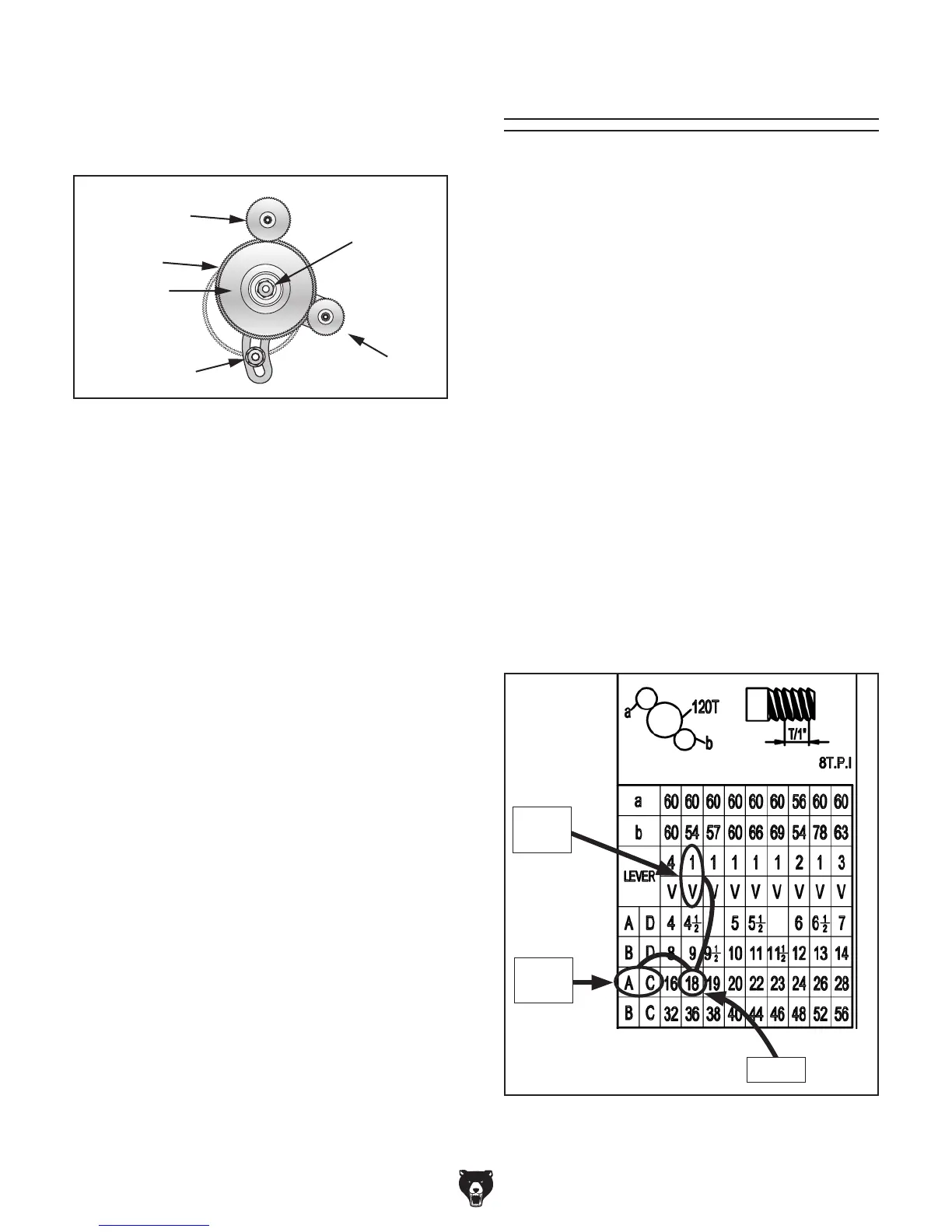

The threading charts on the headstock face dis-

play the settings for inch and metric threading.

Using the controls on the lathe, follow the exam-

ple below to understand how to set up the lathe

for the desired threading operation.

To set dials for 18 TPI:

1. Install the 60T and 54T gears, as instructed in

the Gear Configuration Example on Page

52.

2. Locate 18 TPI on the inch threading chart

below.

Threading

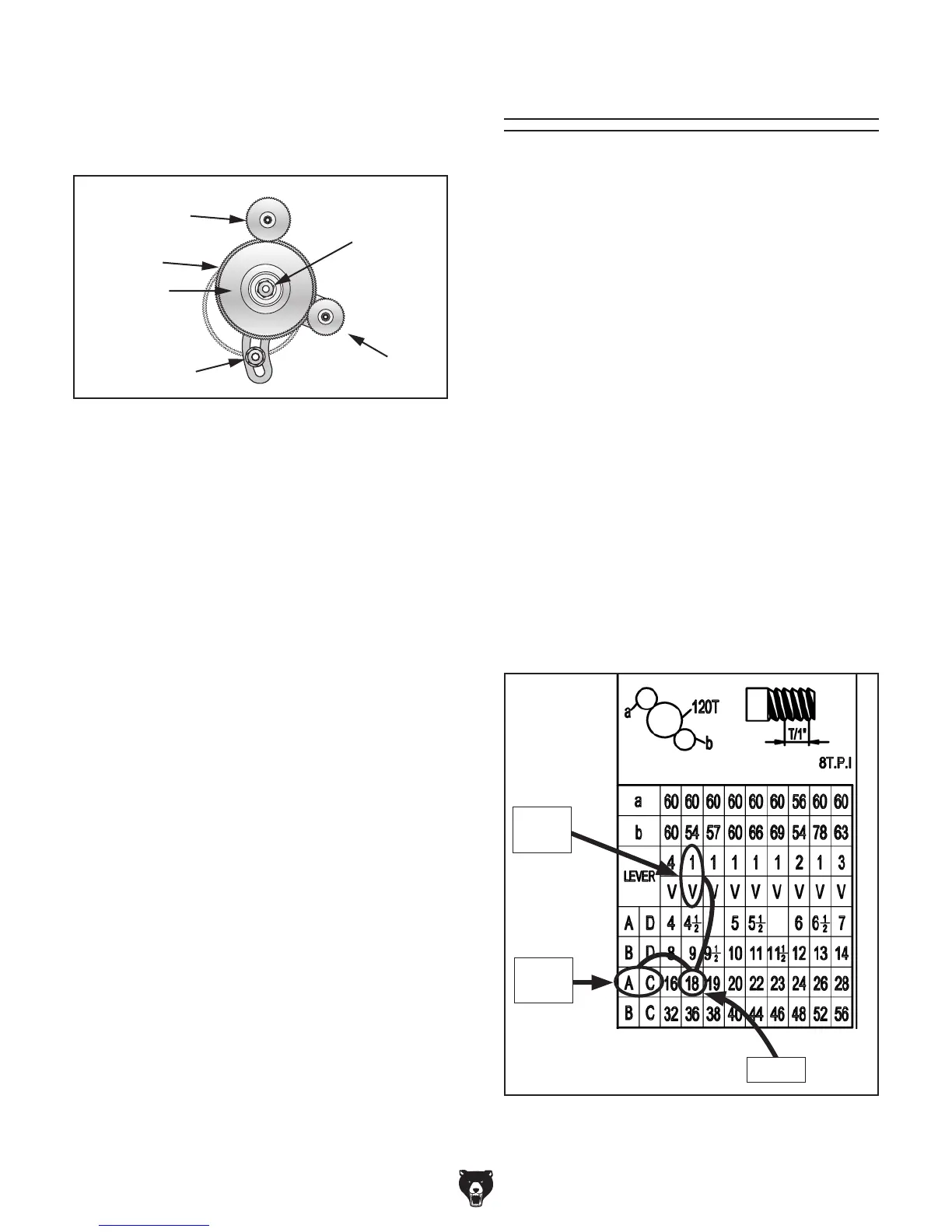

Arm-Support

Hex Nut

Gear-Support

Hex Nut

60T Gear

54T Gear

120T Gear

127T Gear

Figure 79. 60T & 54T gears installed.

11. Rotate the 120T gear up against the 60T gear

until they mesh with 0.002" to 0.004" back-

lash.

12. Tighten the arm support hex nut.

13. Secure the arm support cap screw (see

Figure 77).

14. Re-install the end gear cover.

10. Slide the 120T gear against the lower 54T

gear (see Figure 79) until they mesh with

0.002" to 0.004" backlash, then tighten the

gear support hex nut.

Figure 80. 18 TPI and corresponding dial

positions.

1 & V

Dials

18 TPI

A & C

Dials

Loading...

Loading...