2 OM-SSB-3E/5E/10E & (2)SSB-3E/5E/10E Domestic

IMPORTANT - READ FIRST - IMPORTANT

WARNING: THE UNIT MUST BE INSTALLED BY PERSONNEL QUALIFIED TO WORK WITH

ELECTRICITY AND PLUMBING. IMPROPER INSTALLATION CAN CAUSE

INJURY TO PERSONNEL AND/OR DAMAGE TO THE EQUIPMENT. THE UNIT

MUST BE INSTALLED IN ACCORDANCE WITH APPLICABLE CODES.

CAUTION: SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT.

CAUTION: DO NOT INSTALL THE UNIT IN ANY WAY WHICH WILL BLOCK THE REAR

VENTS, OR WITHIN 2 INCHES OF A HEAT SOURCE SUCH AS A BRAISING PAN,

DEEP FRYER, CHAR BROILER OR KETTLE.

CAUTION: LEVEL THE UNIT FRONT TO BACK, AND PITCH IT SLIGHTLY TO THE FRONT,

TO AVOID DRAINAGE PROBLEMS.

WARNING: FOLLOW THE WIRING DIAGRAM EXACTLY WHEN CONNECTING A UNIT TO

AVOID DAMAGE OR INJURY. WIRING DIAGRAM IS LOCATED ON THE INSIDE

OF THE RIGHT PANEL.

CAUTION: DO NOT USE PLASTIC PIPE. DRAIN MUST BE RATED FOR BOILING WATER.

WARNING: DO NOT CONNECT THE DRAIN DIRECTLY TO A BUILDING DRAIN.

WARNING: BLOCKING THE DRAIN IS HAZARDOUS.

IMPORTANT: IMPROPER DRAIN CONNECTION WILL VOID WARRANTY.

IMPORTANT: DO NOT ALLOW ANY WATER TRAPS IN THE DRAIN LINE. A TRAP CAN CAUSE

PRESSURE TO BUILD UP INSIDE THE CAVITY DURING STEAMING, WHICH

WILL MAKE THE DOOR GASKET LEAK.

WARNING: WHEN YOU OPEN THE DOOR, STAY AWAY FROM STEAM COMING OUT OF

THE UNIT. STEAM CAN CAUSE BURNS.

WARNING: BEFORE CLEANING THE OUTSIDE OF THE STEAMER, DISCONNECT THE

ELECTRIC POWER SUPPLY. KEEP WATER AND CLEANING SOLUTIONS OUT

OF CONTROLS AND ELECTRICAL COMPONENTS. NEVER HOSE OR STEAM

CLEAN ANY PART OF THE UNIT.

WARNING: ALLOW COOKING CHAMBER TO COOL COMPLETELY BEFORE CLEANING.

WARNING: USE MILD CLEANING AGENTS ONLY. CAREFULLY READ THE WARNINGS AND

FOLLOW THE DIRECTIONS ON THE LABEL OF EACH CLEANING AGENT. USE

SAFETY GLASSES AND RUBBER GLOVES AS RECOMMENDED BY CLEANING

AGENT MANUFACTURER.

WARNING: DO NOT PUT HANDS OR TOOLS INTO THE COOKING CHAMBER UNTIL THE

FAN HAS STOPPED TURNING.

WARNING: DO NOT OPERATE THE UNIT UNLESS THE REMOVABLE RIGHT SIDE PANEL

HAS BEEN RETURNED TO ITS PROPER LOCATION.

NOTICE: DO NOT USE A CLEANING AGENT THAT CONTAINS ANY SULFAMIC ACID,

OR ANY CHLORIDE, INCLUDING HYDROCHLORIC ACID. IF THE CHLORIDE

CONTENT OF ANY PRODUCT IS UNCLEAR, CONSULT THE MANUFACTURER.

DO NOT USE A CLEANING OR DELIMING AGENT THAT CONTAINS MORE

THAN 30% PHOSPHORIC ACID.

NOTICE: DO NOT USE ANY DEGREASER THAT CONTAINS POTASSIUM HYDROXIDE OR

SODIUM HYDROXIDE OR THAT IS ALKALINE.

WARNING: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY

GROEN OR THEIR AUTHORIZED DISTRIBUTOR VOIDS ALL WARRANTIES

AND CAN RESULT IN BODILY INJURY TO THE OPERATOR AND DAMAGE THE

EQUIPMENT. SERVICE BY OTHER THAN FACTORY-AUTHORIZED PERSONNEL

WILL VOID ALL WARRANTIES.

WARNING: HIGH VOLTAGE EXISTS INSIDE CONTROL COMPARTMENTS. DISCONNECT

FROM BRANCH CIRCUIT BEFORE SERVICING. FAILURE TO DO SO CAN

RESULT IN INJURY OR DEATH.

INSPECTION & UNPACKING

CAUTION: SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT.

Your Groen SmartSteam100 Boilerless Steamer will be delivered completely

assembled in a heavy shipping carton strapped to a skid. On receipt, inspect carton

carefully for exterior damage.

Carefully cut the straps and detach the sides of the carton from the skid. Pull the

carton up off the unit. Be careful to avoid personal injury or equipment damage

from staples which might be left in the carton walls.

When starting installation, check packing materials to make sure loose parts such

as the condensate drip tray are not discarded with this material.

Write down the model number, serial number and installation date. Keep this

information for reference. Space for these entries is provided at the top of the

Service Log in the back of this manual.

STEAMER Weight (LBS) Weight (KGS)

SSB-3E Table Top 220 100

SSB-3E with Stand 310 141

(2)SSB-3E with Stand 500 227

SSB-5E Table Top 275 125

SSB-5E with Stand 350 159

(2)SSB-5E with Stand 555 252

SSB-10E with Stand 469 213

(2)SSB-10E with Stand 764 347

INSTALLATION & START-UP

WARNING: THE UNIT MUST BE INSTALLED BY PERSONNEL WHO ARE QUALIFIED TO

WORK WITH ELECTRICITY AND PLUMBING. IMPROPER INSTALLATION CAN

CAUSE INJURY TO PERSONNEL AND/OR DAMAGE TO THE EQUIPMENT. THE

UNIT MUST BE INSTALLED IN ACCORDANCE WITH APPLICABLE CODES. THE

UNIT MUST BE INSTALLED BY A LICENSED PLUMBER WHEN INSTALLED

WITHIN THE COMMONWEALTH OF MASSACHUSETTS.

CAUTION: DO NOT INSTALL THE UNIT WITH THE REAR VENTS BLOCKED OR WITHIN 2

INCHES OF A HEAT SOURCE SUCH AS A BRAISING PAN, DEEP FAT FRYER,

CHARBROILER OR KETTLE.

TO AVOID DRAINAGE PROBLEMS, LEVEL THE UNIT FRONT TO BACK, AND

PITCH SLIGHTLY TO THE FRONT.

A. Installation

Minimum Clearances: SmartSteam100 Boilerless Steamer requires the

following minimum clearances to any surface, combustible or noncombustible.

Right Side: 2 inches Left Side: 2 inches Rear: 6 inches

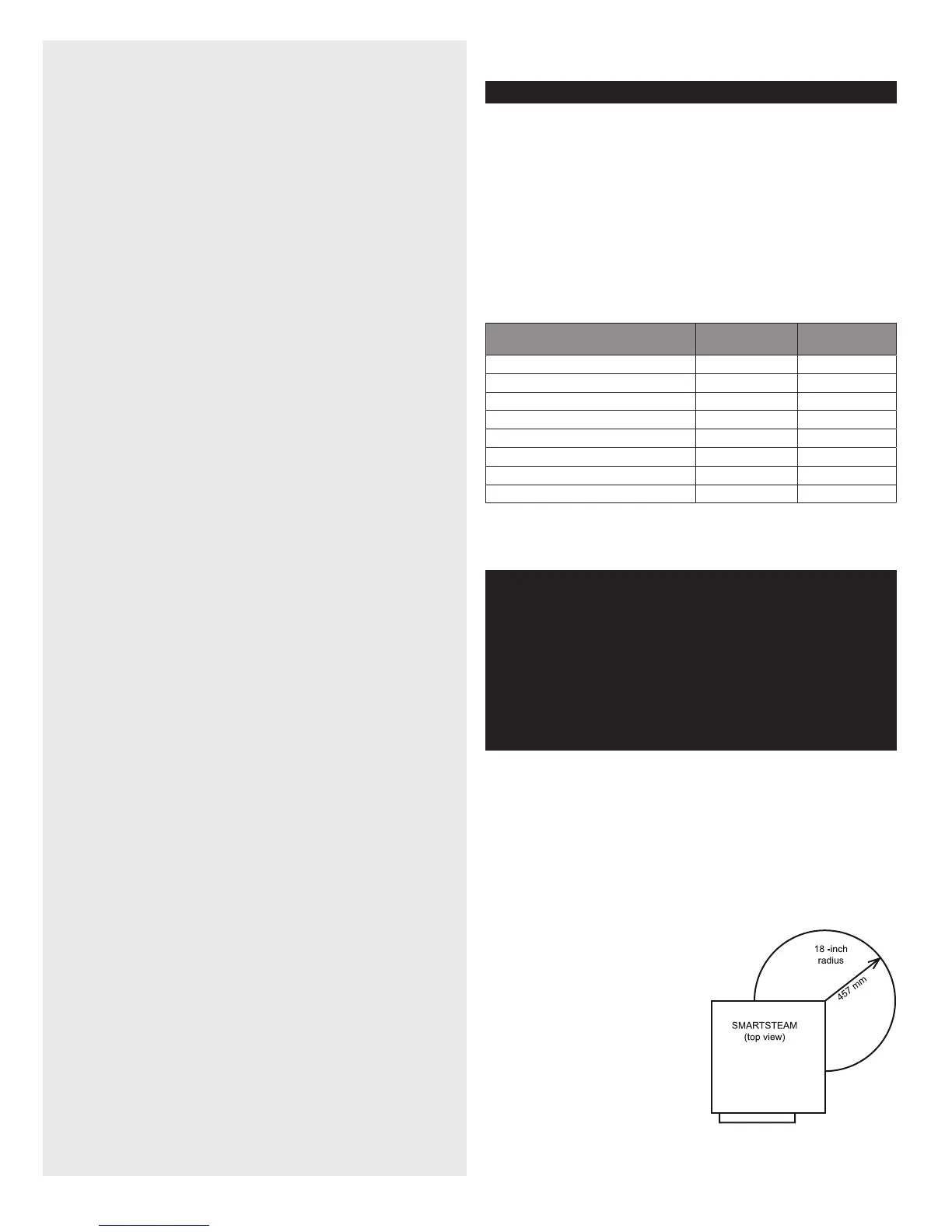

Steam Free Zone: The SmartSteam100 Boilerless Steamer can be damaged by

steam from external sources. Do not install the steamer over a steam venting

drain. Ensure that steam is not present in an area bounded by the footprint of

the steamer and a circle 18 inches in radius about the right rear corner of the

steamer (see figure below).

Install and operate the gas appliance

in a well ventilated area. Adequate

air must be supplied to replenish the

air used for combustion. Installation

must conform with local codes and/

or with the Naitonal Fuel Gas Code,

ANSI Z223.1/NFPA-54 (latest edition)

or the National Gas and Propane

Code CSA B149.1 as applicable.

Any item which might obstruct or

restrict the flow of air for combustion

and ventilation must be removed. Do not obstruct the flue cover or rear vents

after installation.

Loading...

Loading...