4 OM-SSB-3E/5E/10E & (2)SSB-3E/5E/10E Domestic

1. Dual Water Connections

The same water supply connection is used for both units. At the water inlet

valve a 3/4 inch female NH connector (garden hose type) is used for the

water supply.

2. Electrical Supply Connection

Separate electrical connections will be required for each steamer to be

stacked. Each steamer unit must have it’s own branch circuit protection.

3. Drain Connection

Steamers must be leveled front to back, and pitched to the front (maximum

1/4 inch) by adjusting the bullet feet on the cabinet or stand base.

For all factory-stacked SSB steamers, a 21/2 inch ID hose is attached to

the unit drain. It must be rated for boiling water.

F. Counter-Mounted Units

WARNING: DO NOT STACK SSB STEAMERS WHEN LEGS ARE USED.

This section is applicable if the steamer will be mounted to a counter. All four

edges of the bottom of the steamer must be sealed with RTV to the counter

if the 4 inch legs are not used. Counter must be made of a noncombustible

material such as metal or tile.

INITIAL START-UP

WARNING: WHEN YOU OPEN THE DOOR, STAY AWAY FROM STEAM COMING OUT OF

THE UNIT. STEAM CAN CAUSE BURNS.

After the SmartSteam100 Boilerless Steamer has been installed, test it to ensure

that the unit is operating correctly.

1. Remove all literature and packing materials from the interior and exterior of

the unit.

2. Make sure the water supply line is open.

3. Turn on electrical service to the unit. The steamer will not operate without

electrical power. Do not attempt to operate the unit during a power failure.

NOTE: The door MUST be closed for the main burner to work.

4. To turn the unit on, press the ON switch on the control panel.

5. When the steam generating reservoir has filled with water, the main burners

will ignite automatically. Within 20 minutes or less the READY light will come

on, indicating that the water has reached its standby temperature. When the

READY light is displayed, you may take any one of the following steps;

a. Push TIMED and set the timer knob to the desired steaming time.

b. Push MANUAL for continuous steaming.

c. Push STOP to let the unit stay at ready condition.

6. To shut down the unit, press the OFF switch. The steam generating reservoir

will then fill with cold water and drain.

7. If the steamer operates as described, the unit is functioning correctly and

ready for USE.

NOTE: For operation at high altitudes (2000 feet and above), please consult the

Groen Foodservice Engineering Department.

OPERATION

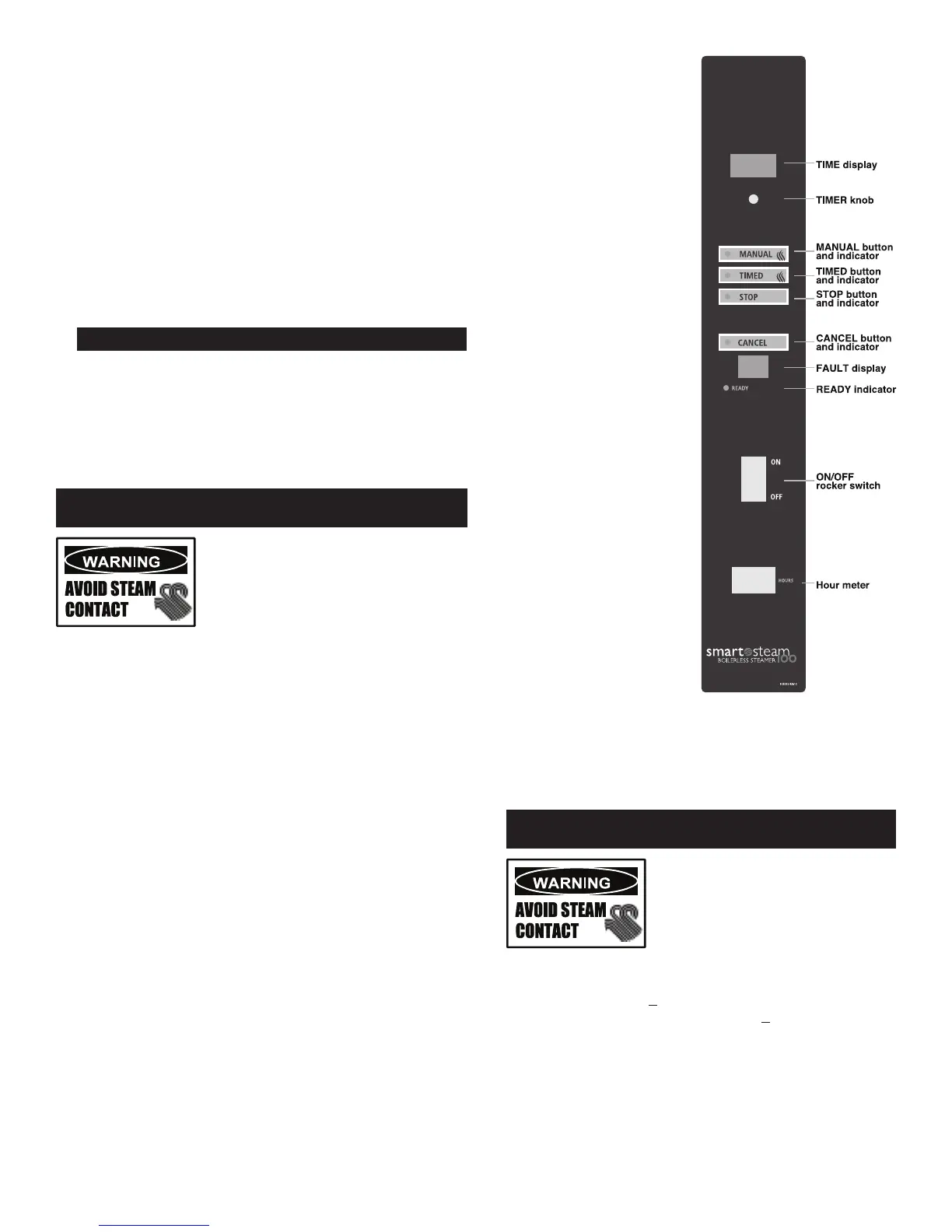

A. Controls

Operator controls are on the front

right of the unit. The control panels

have the following touch pads and

indicator lights:

• The TIME display shows the

remaining cooking time. It

displays three dashes in

MANUAL mode.

• The ON/OFF rocker switch gets

the SmartSteam100 ready for

use or shuts it off.

• The READY indicator light

indicates the unit has

• Hour meter records cumulative

hours of operation.

• The FAULT display shows the

current fault. achieved the

ready temperature.

The push button operations:

1. In the STOP mode the steam

generator stays at a low boil or

ready temperature.

2. When the TIMED button is

pushed , the TIMED light will

illuminate and time can be

set by turning the TIMER knob

(cook time can be increased

or decreased at any time by

turning the timer knob). The

unit steams until the timer

counts down to zero and the

temperature drops to ready. At

that time the STOP light illuminates and a beeper sounds.

3. When the MANUAL button is pushed, the unit steams continuously. The

MANUAL light will stay illuminated.

4. CANCEL button should be pushed to stop beeping.

B. Operating Procedure

WARNING: WHEN YOU OPEN THE DOOR, STAY AWAY FROM STEAM COMING OUT

OF THE UNIT. STEAM CAN CAUSE BURNS.

1. Press the ON/OFF rocker to the ON position, (Fi_) is displayed in the

TIME display window. The steam generating reservoir will begin filling,

displaying (Fi=) and (Fi

=

) as it fills. After initial fill the unit will begin

draining displaying (Fi=), refilling displaying (Fi

=

), and then begin heating

until the READY light comes on (about 15-20 minutes).

2. Load food into pans in uniform layers. Pans should be filled to about the

same levels, and should not be mounded.

3. Open the door and slide the pans into the supports. If you will only be

steaming one pan, put it in the middle position. Some foods will cause

foam. When cooking foods that foam, such as shrimp, put an empty solid

2½” deep pan in the bottom slot of the pan racks.

Loading...

Loading...