10.2 Setpoint in closed-loop control

The setpoint is written to register 00104 Setpoint as a percentage

value scaled in 0.01 % of the setpoint range. The selected setpoint

is reflected in register 00338 UserSetpoint with the same scaling.

The actual setpoint, whether it has been set via Grundfos GO, the

pump display, the pump buttons or the fieldbus, can be read from

register 00308 ActualSetpoint. It is a percentage value scaled in

0.01 % of register 00211 FeedbackSensorMax.

Generally, the actual setpoint value represents head, pressure, flow,

temperature and so on depending on how the feedback sensor has

been set to measure. The unit of measure can be read from register

00209 FeedbackSensorUnit.

It is easy to calculate back and forth between the setpoint in percent

and its scaled value:

X

act

[unit] = X

set

[%] × (r

max

- r

min

) + r

min

Where:

• r

max

= SetpointRangeMax × FeedbackSensorMax ×

FeedbackSensorUnit

• r

min

= SetpointRangeMin × FeedbackSensorMax ×

FeedbackSensorUnit

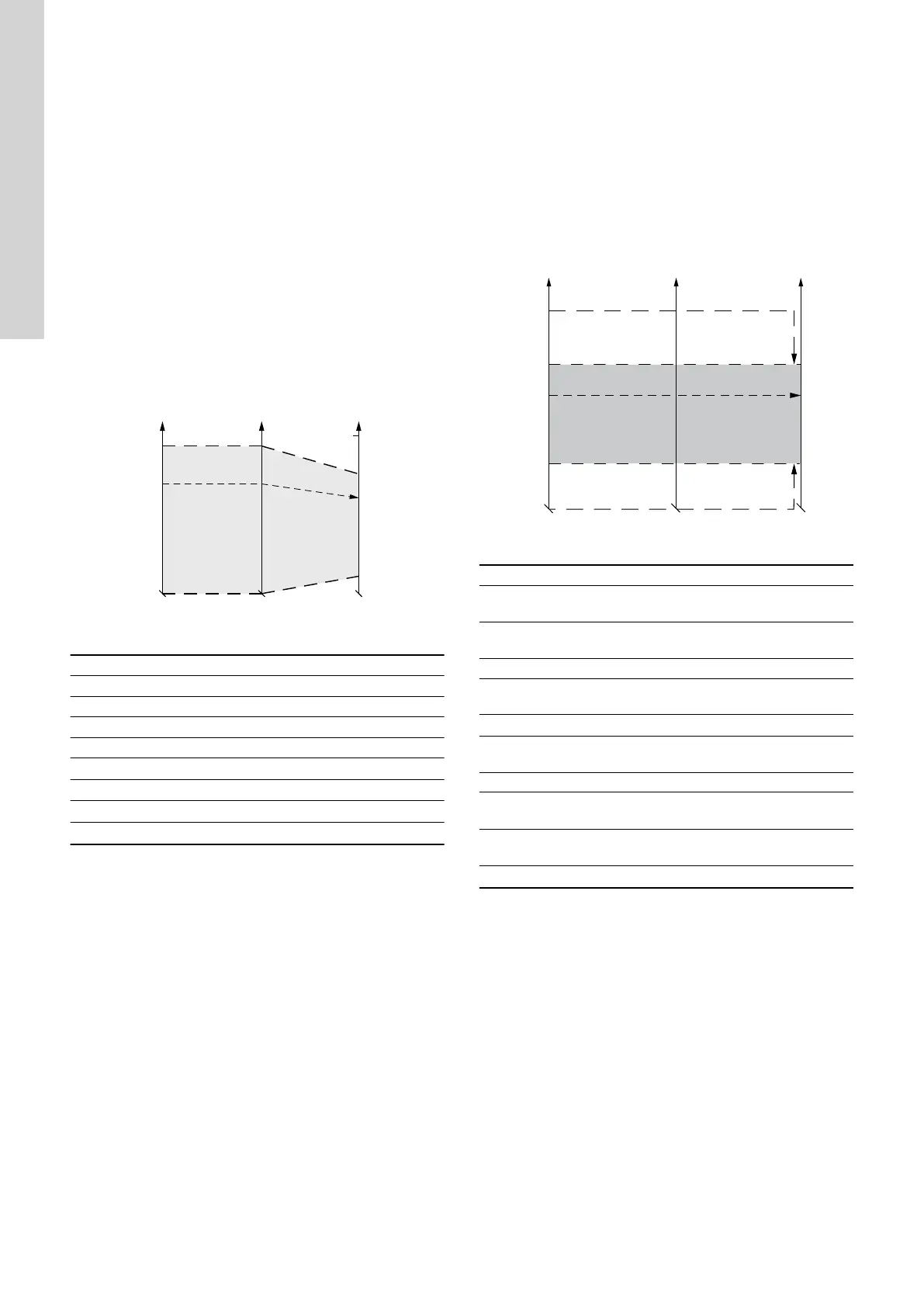

TM079761

Setpoint in closed-loop control

Pos. Description

1

Setpoint

7)

(Register 00104)

2

UserSetpoint

7)

(Register 00343)

3

ActualSetpoint

8)

(00308)

4 FeedbackSensorMax (Register 00222)

5

r

max

6

X

set

7

X

act

8

r

min

7)

Percentage of setpoint range.

8)

Percentage of sensor maximum.

MAGNA3 40-100 example

SetpointRangeMin: 5 %.

SetpointRangeMax: 50 %.

FeedbackSensorMax: 20.

FeedbackSensorUnit: m.

r

max

= SetpointRangeMax × FeedbackSensorMax ×

FeedbackSensorUnit = 50 % × 20 × m = 10 m

r

min

= SetpointRangeMin × FeedbackSensorMax ×

FeedbackSensorUnit = 5 % × 20 × m = 1 m

X

act

[unit] =

X

set

[%] × (r

max

- r

min

) + r

min

X

set

[%] × (10 m - 1 m) + 1 m

X

set

[%] × 9 m + 1 m

If X

set

[%] has value 40 %, the pump will have an actual setpoint of

40 % × 9 m + 1 m = 4.6 m.

10.3

Setpoint in open-loop control

The setpoint is written to register 00104 Setpoint as a percentage

value scaled in 0.01 % of the nominal frequency f

nom

represented

by register 00212 NomFrequency. The selected setpoint is reflected

in register 00338 UserSetpoint with the same scaling. From

fieldbus, it will get whatever value written to Setpoint. From pump

display and Grundfos GO, it is limited to range [f

min

; f

max

],

represented by 00214 MaxFrequency and 00213 MinFrequency.

The actual setpoint, whether it has been set via Grundfos GO, the

pump display, the pump buttons or the fieldbus, can be read from

register 00308 ActualSetpoint, and it always reflects the frequency

limitations. It equals the value that the pump actually uses.

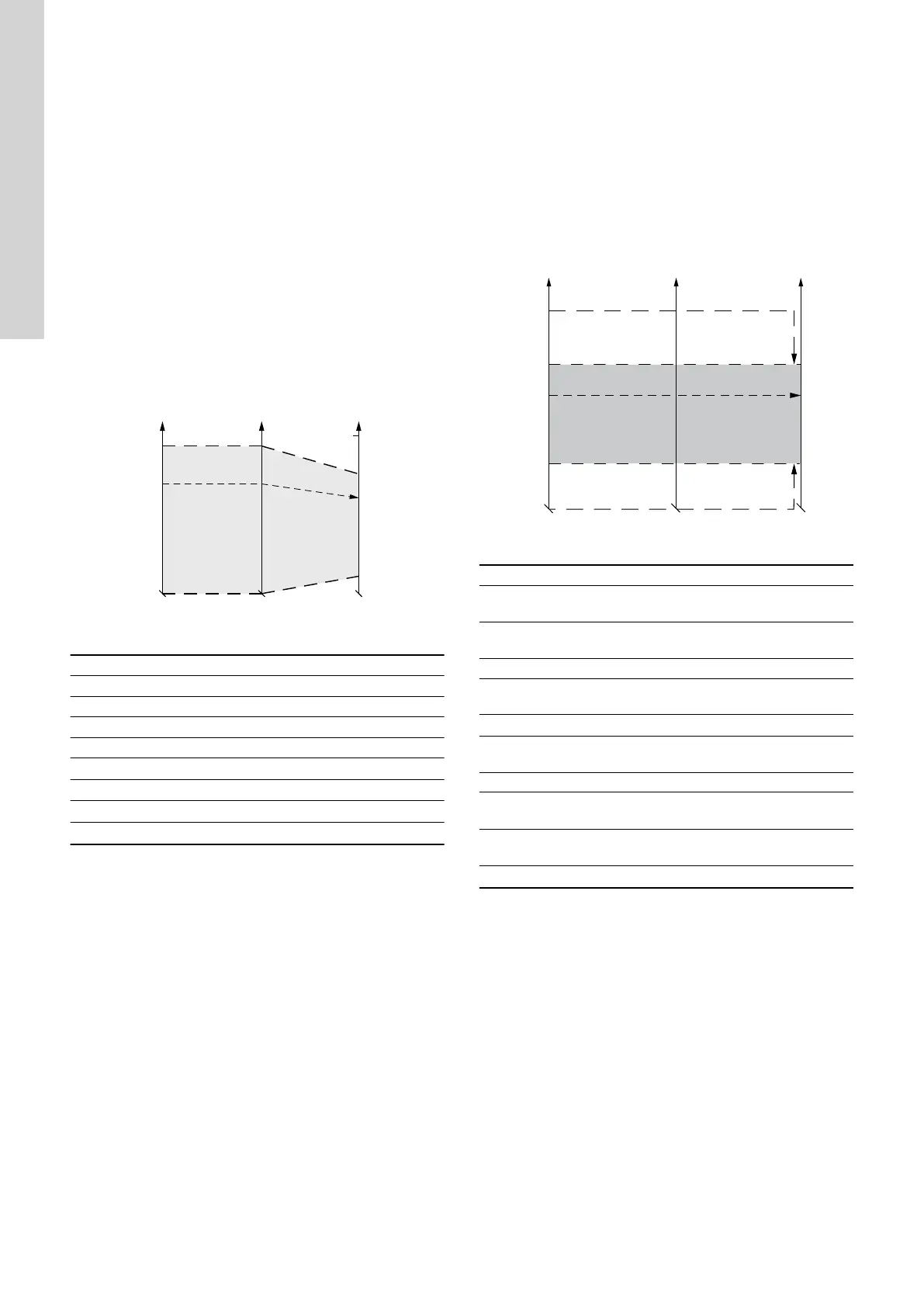

TM070155

Setpoint in open-loop control

Pos. Description

1

Setpoint

9)

(Register 00104)

2

NomFrequency, Hz

(Register 00212)

3 100 %

4

MaxFrequency

(Register 00214)

5

X

set

6

MinFrequency

(Register 00213)

7 0 %

8

UserSetpoint

9)

(Register 00338)

9

ActualSetpoint

9)

(Register 00308)

10

X

act

9)

Percentage of f

nom

.

For MGE motors and the CUE drive

• [f

min

; f

max

] can be adjusted from the pump display and Grundfos

GO.

• With f

max

> f

nom

a setpoint above 100 % is possible, over

synchronous.

For MAGNA3

• [f

min

; f

max

] are fixed.

• f

max

always equals f

nom

.

30

English (GB)

Loading...

Loading...