English (US)

22

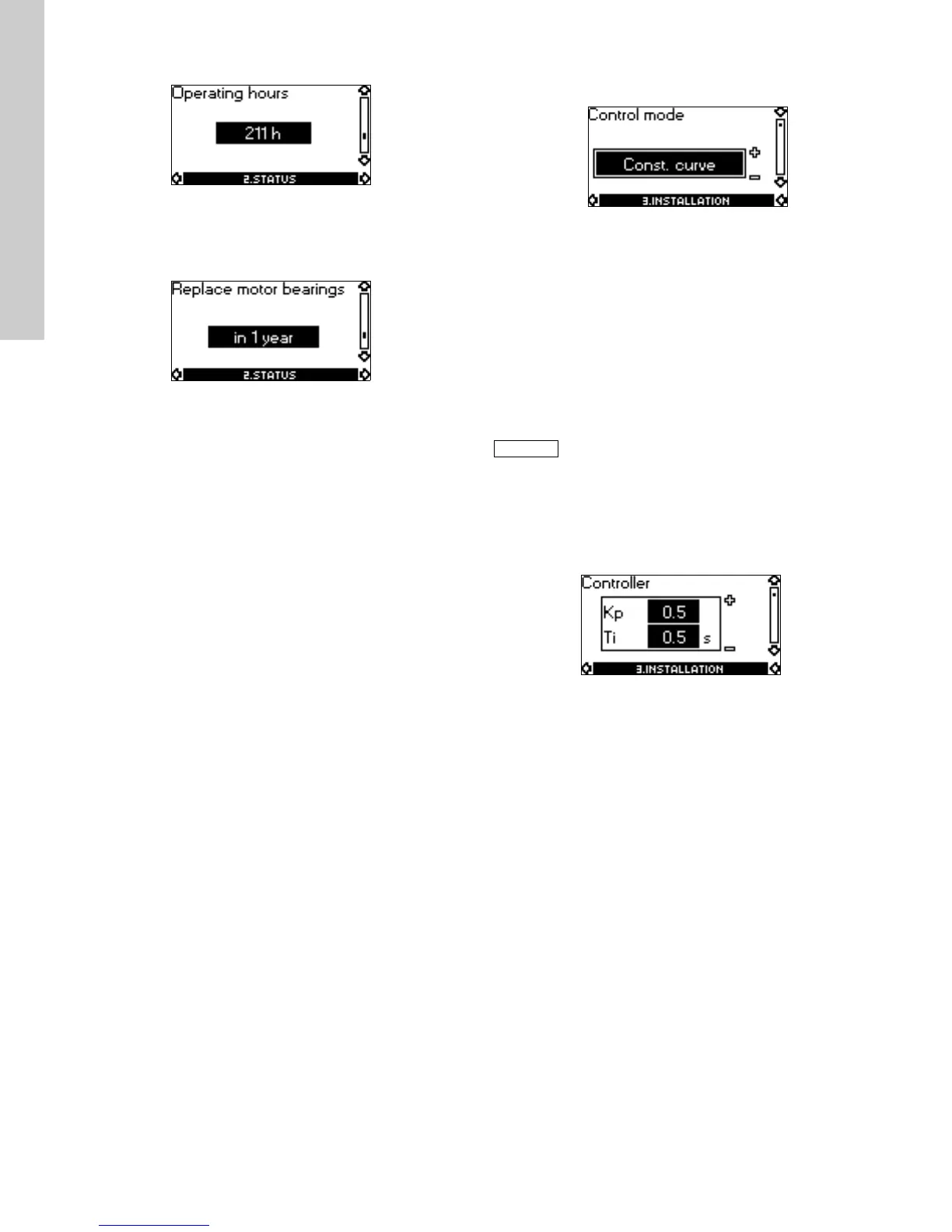

Operating hours

Tolerance: ± 2 %.

The value of operating hours is an accumulated value and cannot

be reset.

Replace motor bearings

This display shows when to replace the motor bearings.

The controller monitors the operating pattern of the motor and

calculates the period between bearing replacements.

Displayable values:

• in 2 years

• in 1 year

• in 6 months

• in 3 months

• in 1 month

• in 1 week

•Now!

10.3.4 INSTALLATION menu

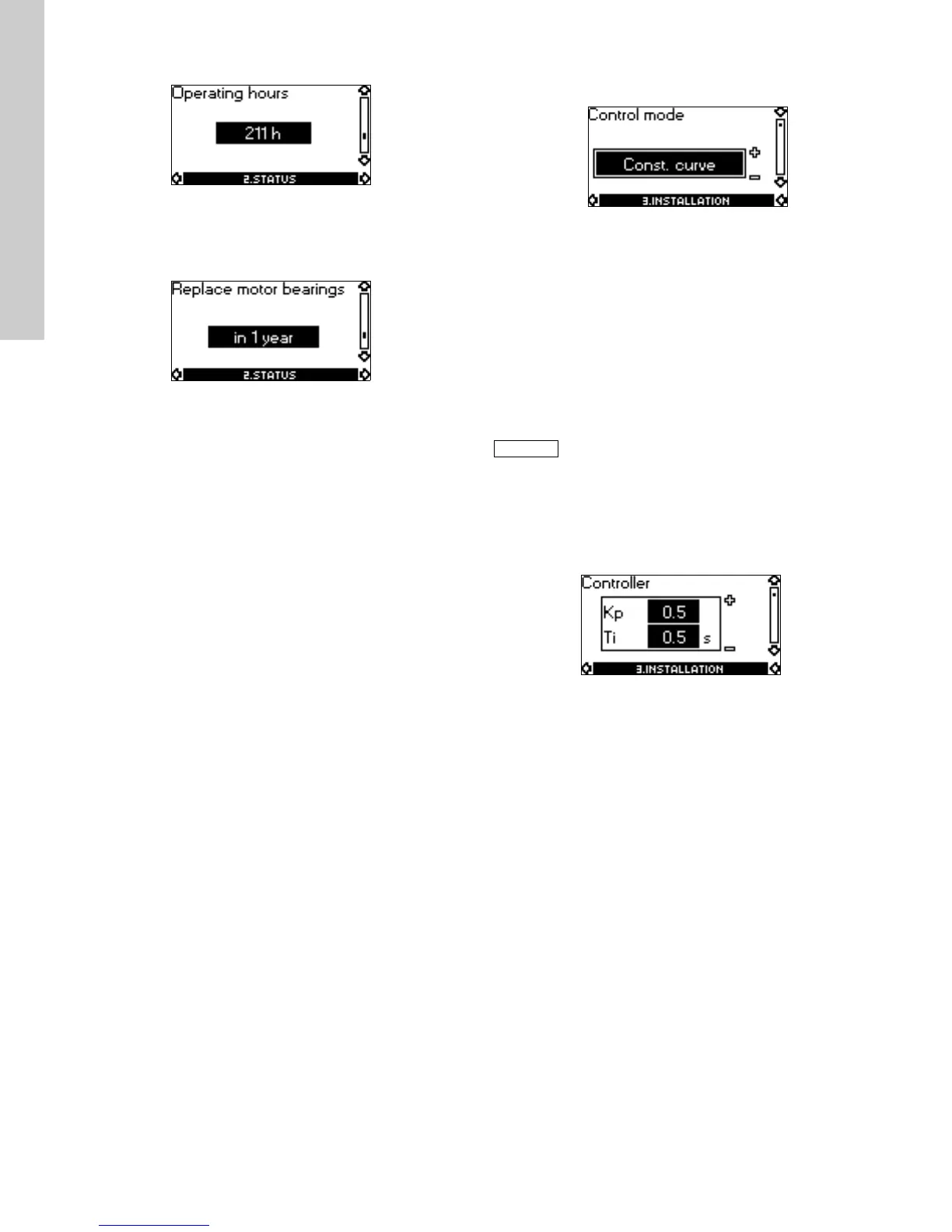

Control mode

Select one of the following control modes:

• Const. pressure

• Const. diff. press.

• Const. temperature

• Const. diff. temp.

• Const. flow rate

•Const. level

•Const. curve

• Const. other value.

See section 9. Operating and control modes for further

information.

Controller

E-pumps have a factory default setting of gain (K

p

) and integral

time (T

i

). However, if the factory setting is not the optimum

setting, the gain and the integral time can be changed in this

display below:

• Set the gain (K

p

) within the range from 0.1 to 20.

• Set the integral-action time (T

i

) within the range from 0.1 to

3600 s.

If 3600 s is selected, the controller will function as a P

controller.

• Furthermore, the controller can be set to inverse control,

meaning that if the setpoint is increased, the speed will be

reduced. In the case of inverse control, the gain (K

p

) must be

set within the range from -0.1 to -20.

If the pump is connected to a bus, the control

mode cannot be selected via the R100. See

section 12. Bus signal.

Loading...

Loading...