11

6.3 Pump mounting

6.3.1 Recommended installation torques

6.4 Suction pipe

The suction pipe should be adequately sized and run as straight and

short as possible to keep friction losses to a minimum (minimum of

four pipe diameters straight run prior to the suction flange). Avoid

using unnecessary fittings, valves or accessory items. Butterfly or

gate valves should only be used in the suction line when it is

necessary to isolate a pump because of a flooded suction condition.

This would occur if the water source is above the pump; see fig. 5

and fig. 6. Flush piping prior to pump installation to remove loose

debris.

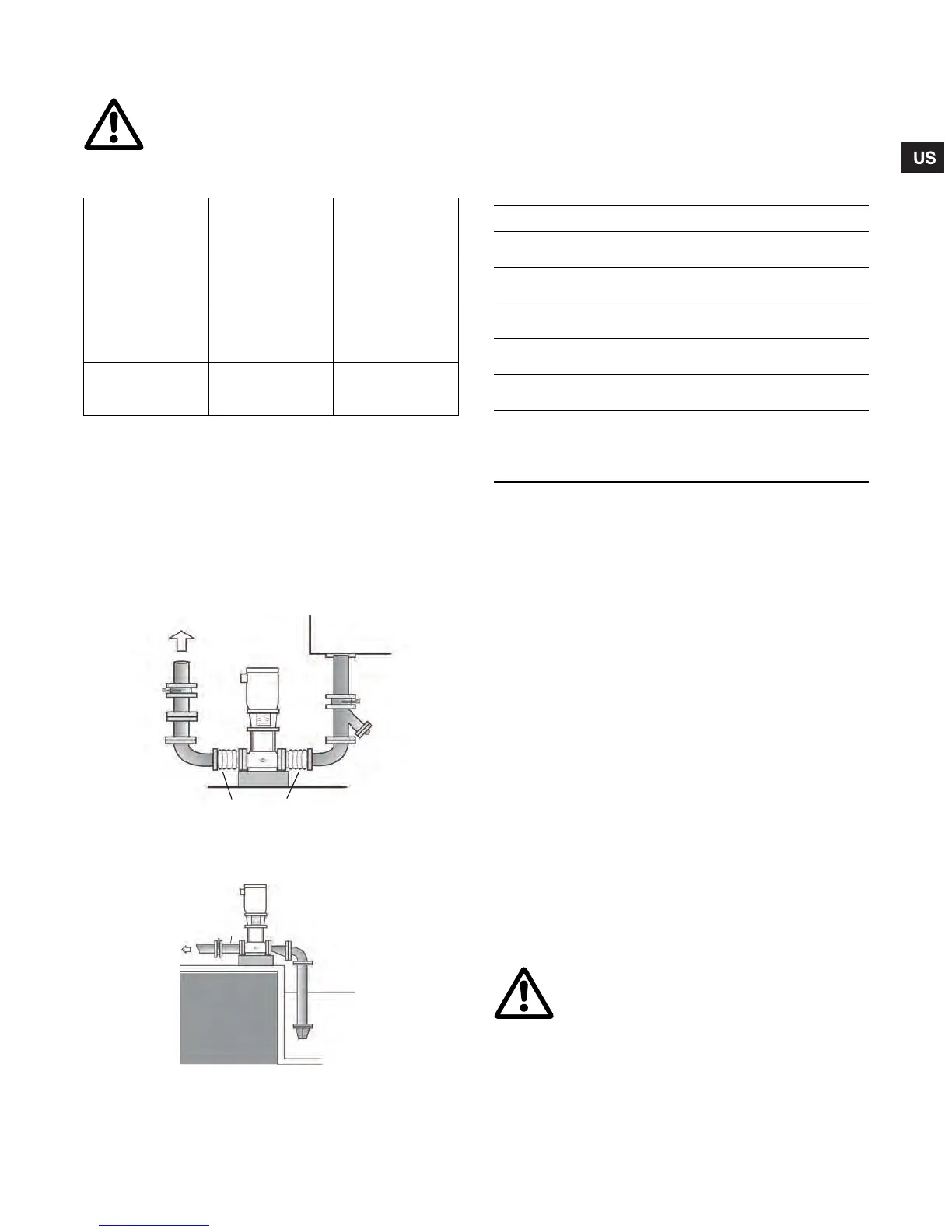

Fig. 5 Flooded suction

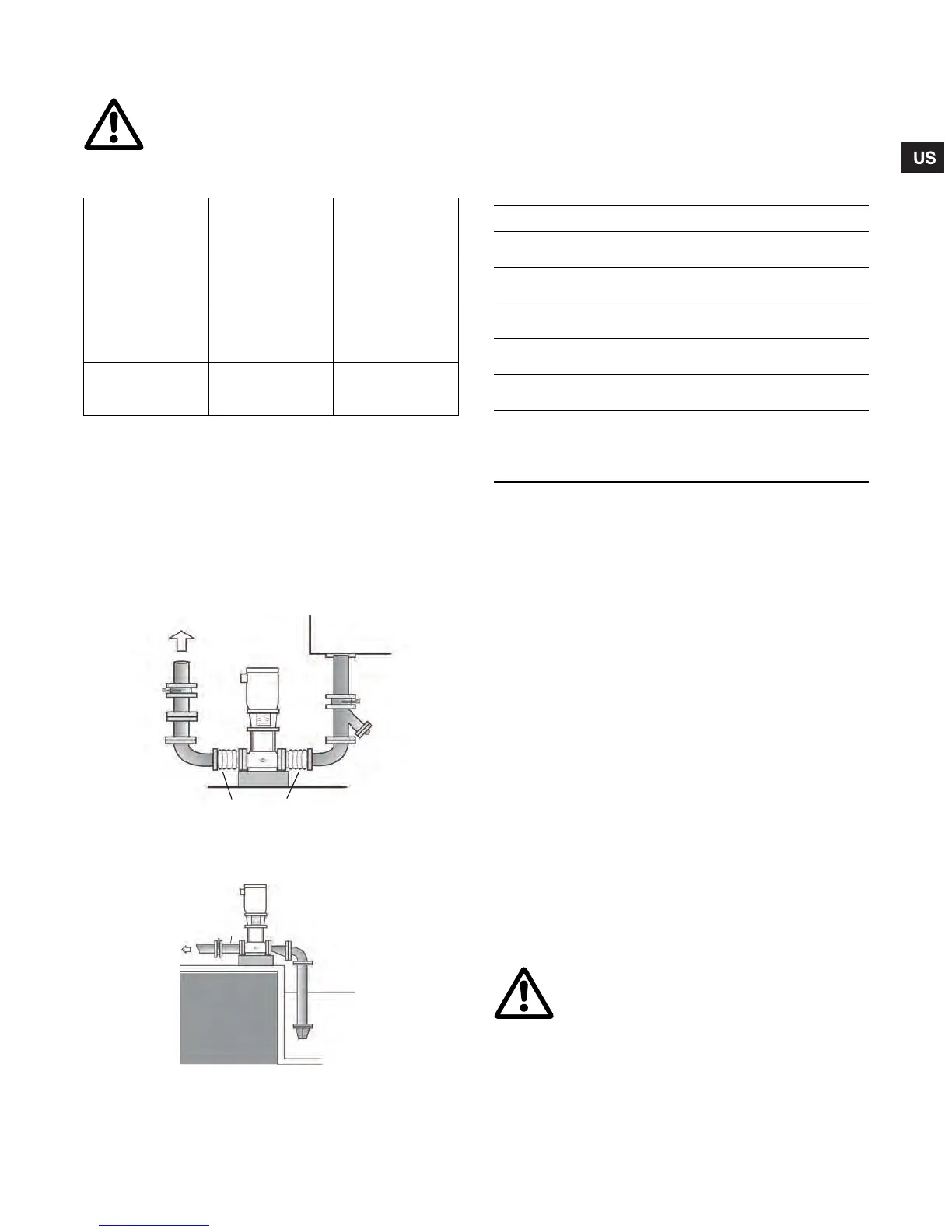

Fig. 6 Suction lift*

*The suction pipe should have a fitting on it for priming.

CRN-SF pumps cannot be used for suction lift.

6.5 Minimum suction pipe sizes

The following recommended suction pipe sizes are the smallest

sizes which should be used with any specific CR pump type.

The suction pipe size should be verified with each installation to

ensure good pipe practices are being observed and excess

friction losses are not encountered.

High temperatures may require larger diameter pipes to reduce

friction and improve NPHSA.

6.6 Discharge piping

It is suggested that a check valve and isolation valve be installed

in the discharge pipe.

Pipe, valves and fittings should be at least the same diameter as

the discharge pipe or sized in accordance with good piping

practices to reduce excessive fluid velocities and pipe friction

losses.

Note: Pipe, valves and fittings must have a pressure rating equal

to or greater than the maximum system pressure.

Before the pump is installed it is recommended that the discharge

piping be pressure checked to at least the maximum pressure the

pump is capable of generating or as required by codes or local

regulations.

Whenever possible, avoid high pressure loss fittings, such as

elbows or branch tees directly on either side of the pump. The

piping should be adequately supported to reduce thermal and

mechanical stresses on the pump.

Good installation practice recommends the system be thoroughly

cleaned and flushed of all foreign materials and sediment prior to

pump installation. Furthermore, the pump should never be

installed at the lowest point of the system due to the natural

accumulation of dirt and sediment. If there is excessive sediment

or suspended particles present, it is advised a strainer or filter be

used. Grundfos recommends that pressure gauges be installed

on inlet and discharge flanges or in pipes to check pump and

system performance.

Warning

CR, CRI, CRN pumps are shipped with covered

suction and discharge. The covers must be

removed before the final pipe flange to pump

connections are made.

Model

Recommended

foundation torque

(ft - lbs)

Recommended

flange torque

(ft - lbs)

CR, CRI, CRN

1s/1/3/5, and

CRT 2/4

30 37 - 44

CR, CRI,

CRN 10/15/20, and

CRT 8/16

37 44 - 52

CR, CRN

32/45/64/90/

120/150

52 52 - 59

TM04 3925 0409

TM04 3910 0409

Reservoir

Butterfly

Valve

Butterfly

Valve

Strainer

Check

Valve

Expansion Joint

Butterfly

Valve

Check

Valve

Eccentric

Reducer

Suction

Pipe

Reservio

Foot

Valve

Model Min. suction pipe size

CR(I)(N) 1s, 1, 3; CRT 2 1"

Nominal diameter

sch 40 pipe

CR(I)(N) 5;

CRT 4

1-1/4"

Nominal diameter

sch 40 pipe

CR(I)(N) 10, 15, 20;

CRT 8, 16

2"

Nominal diameter

sch 40 pipe

CR(N) 32 2-1/2"

Nominal diameter

sch 40 pipe

CR(N) 45 3"

Nominal diameter

sch 40 pipe

CR(N) 64, 90 4"

Nominal diameter

sch 40 pipe

CR(N) 120, 150 5"

Nominal diameter

sch 40 pipe

Warning

To avoid problems with waterhammer, fast

closing valves must not be used in CRN-SF

applications.

Grundfos.bk Page 11 Wednesday, March 18, 2009 10:38 AM

Loading...

Loading...