18

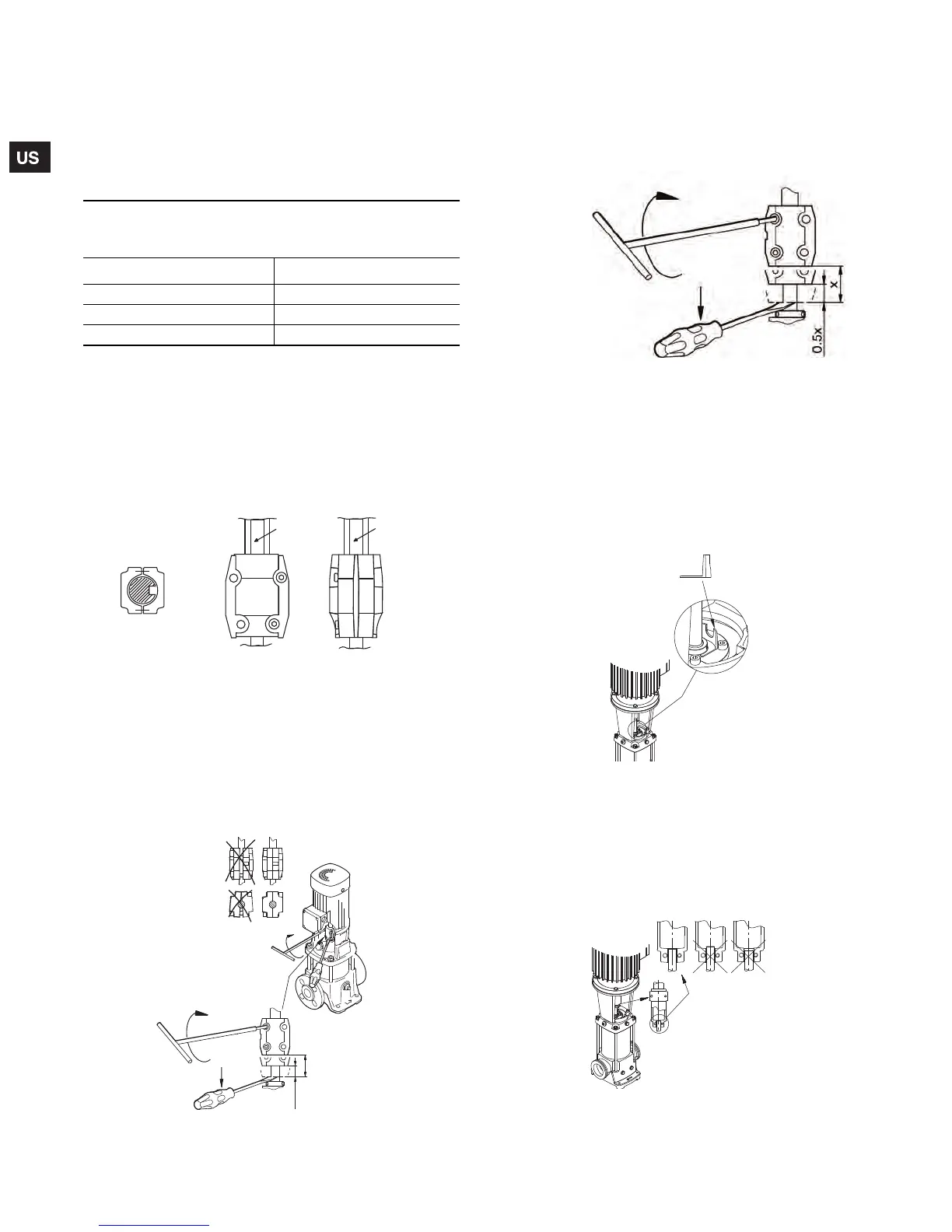

10.2.1 Torque specifications for CR 1s, 1, 3, and 5

Insert shaft pin into shaft hole. Reinstall the coupling halves onto

shaft and shaft pin. Reinstall the coupling screws and leave

loose. Check that the gaps on either side of the coupling are

even, and that the motor shaft keyway is centered in the coupling

half, as shown in fig. 16.

Tighten the screws to the correct torque; see torque

specifications table below.

10.2.2 CR 10, 15 and 20

Insert shaft pin into shaft hole. Insert plastic shaft seal spacer

beneath shaft seal collar. Reinstall the coupling halves onto shaft

and shaft pin. Reinstall the coupling screws and leave loose.

Check that the gaps on either side of the coupling are even and

that the motor shaft key way is centered in the coupling half, as

shown in fig. 16. Tighten the screws to the correct torque.

Remove plastic shaft seal spacer and hang it on inside of

coupling guard.

Fig. 16 Coupling adjustment all CR(I)(N)(X)(T)

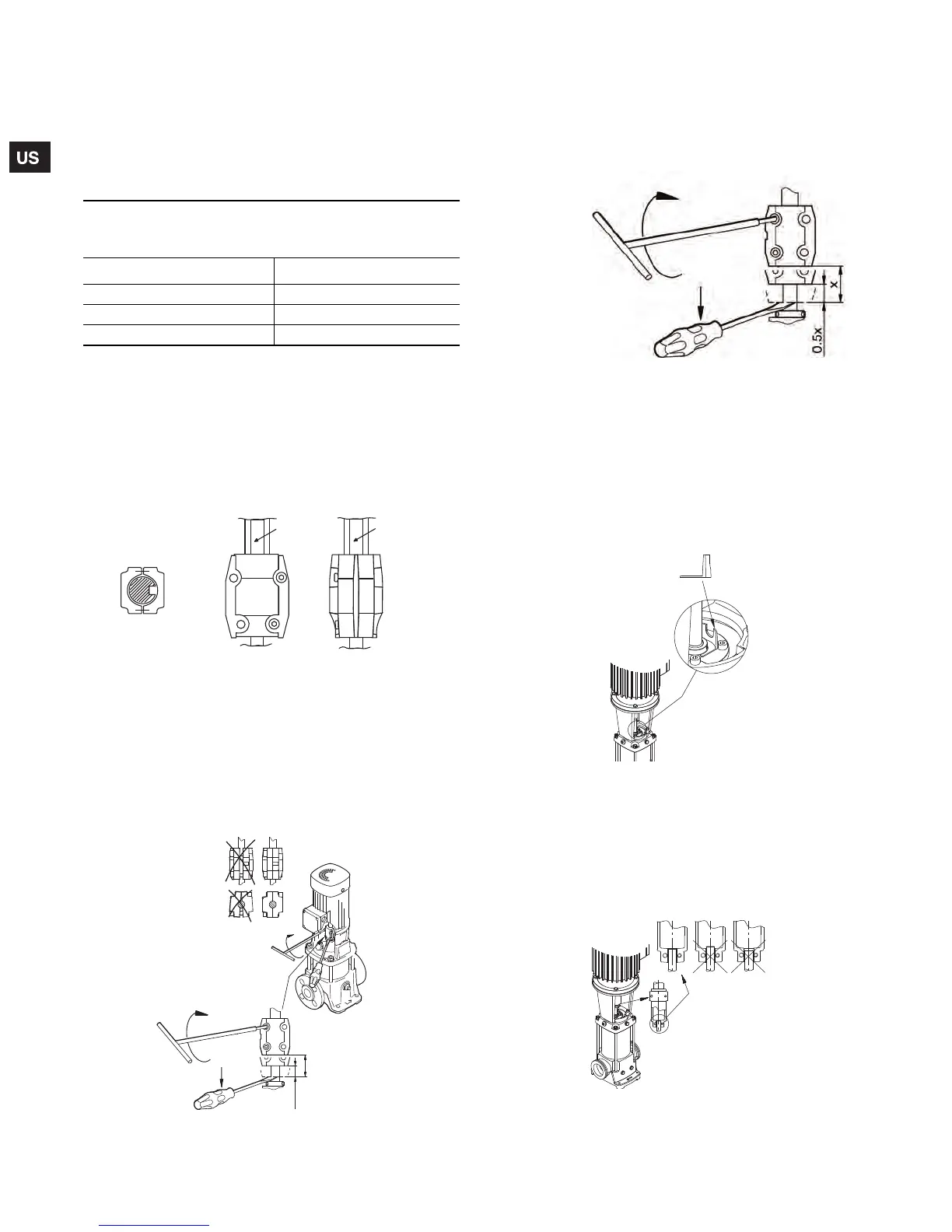

10.2.3 CRT 2, 4, 8 and 16

Reinstall coupling halves. Make sure the shaft pin is located in

the pump shaft. Put the cap screws loosely back into the coupling

halves.

Using a large screwdriver, raise the pump shaft by placing the tip

of the screwdriver under the coupling and carefully elevating

coupling to its highest point; see fig. 17.

Fig. 17 Coupling adjustment CRT 2, 4, 8, and 16

Note: The shaft can only be raised approximately 0.20 in (5mm).

Now lower the shaft halfway back down the distance you just

raised it and tighten the coupling screws (finger tight) while

keeping the coupling separation equal on both sides. When the

screws are tight enough to keep the couplings in place, then

torque the screws evenly in a criss-cross pattern.

Fig. 18 Coupling adjustment clearance CRT 2, 4, 8, and 16

10.2.4 CR(N) 32, 45, 64, 90, 120, and 150

1. Make sure shaft is all the way down. TIghten the set screws on

the mechanical seal.

2. Place the plastic adjustment fork under the cartridge seal

collar; see fig. 19.

Fig. 19 Coupling adjustment

CR(N) 32, 45, 64, 90, 120, and 150

3. Fit the coupling on the shaft so that the top of the pump shaft

is flush with the bottom of the clearance chamber in the

coupling; see fig. 20.

Note: To avoid damaging the coupling halves, ensure that no

portion of the keyway on the motor shaft lies within the gap

between the two coupling halves.

Fig. 20 Coupling adjustment clearance

CR(N) 32, 45, 64, 90, 120, and 150

Torque specifications

CR(I)(N) 1s, 1, 3, 5, 10, 15, and 20

CRT 2, 4, 8, and 16

Coupling bolt size Min. torque

M6 10 ft-lb

M8 23 ft-lb

M10 46 ft-lb

TM04 3919 0409

TM02 1051 0501

CORRECT

CORRECT NOT CORRECT

TOP

View

Gap between coupling

Keyway Keyway

M6 - 13 Nm

M8 - 31 Nm

M10 - 62 Nm

0.5x

x

TM02 1051 0501TM04 3913 0409

TM04 3914 0409

• Note the

clearance

below the

coupling

• Raise the

coupling higher,

as far as it will go

• Lower it halfway

back down

(1/2 the distance

you just raised it)

• Tighten screws

(see torque

specifications

below)

Grundfos.bk Page 18 Wednesday, March 18, 2009 10:38 AM

Loading...

Loading...