Functions

Grundfos CUE

23

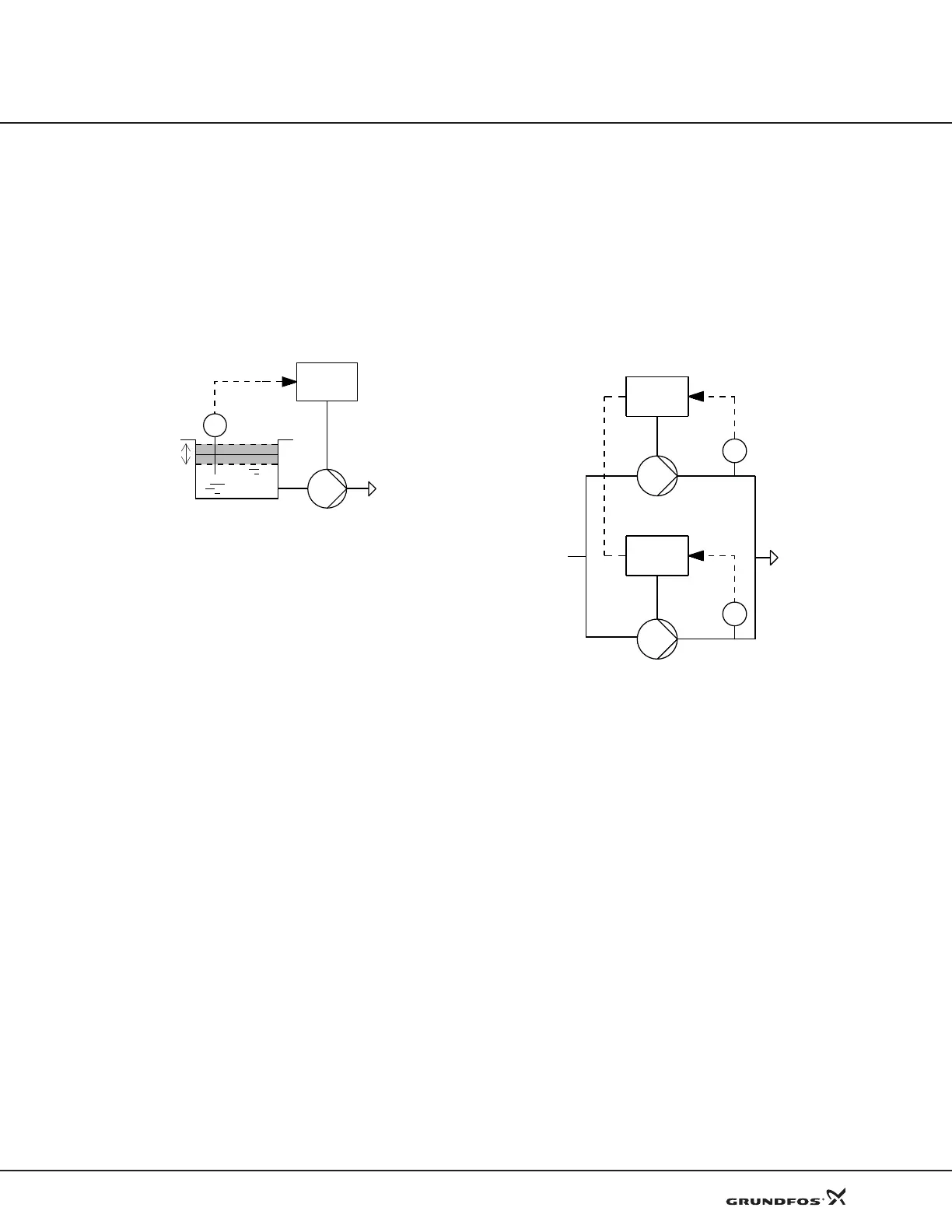

Constant level with stop function

The purpose of the stop function is to stop the pump

when low or no flow is detected.

Note: It

is only possible to set constant level with stop

function if the system incorporates a level sensor, and

all valves can be closed.

When low flow is detected, the pump is in on/off opera-

tion. If there is flow, the pump will continue operating

accord

ing to the setpoint. See fig. 25.

Fig. 25 Constant level with stop function. Difference be-

tween start and stop levels (ΔH)

Low flow can be detected in two different ways:

• with the built-in low-flow detection function

• with a flow switch connected to a digital input.

Low-flow detection function

The low-flow detection function will check the flow reg-

ularly by measurement of speed and power.

Low-flow detection with flow switch

When a flow switch detects low flow, the digital input

w

ill be activated.

Dry-running protection

This function protects the pump against dry running.

When lack of inlet pressure or water shortage is

detected, the pump will be stopped before being dam-

aging.

Lack of inlet pressure or water shortage can be

dete

cted in two ways:

• With a switch connected to a digital input configured

t

o dry-running protection.

• The CUE checks if the shaft power is below a dry-

pump limit for a configurable time (setting via PC

Tool).

The use of a digital input requires an accessory, such

as:

• a Grundfos Liqtec

®

dry-running switch

• a pressure switch installed on the suction side of the

pump

• a float switch installed on the suction side of the

pump.

The pump cannot restart as long as the input is acti-

vated. Restart may be delayed by up to 30 minutes,

dep

ending of the pump family.

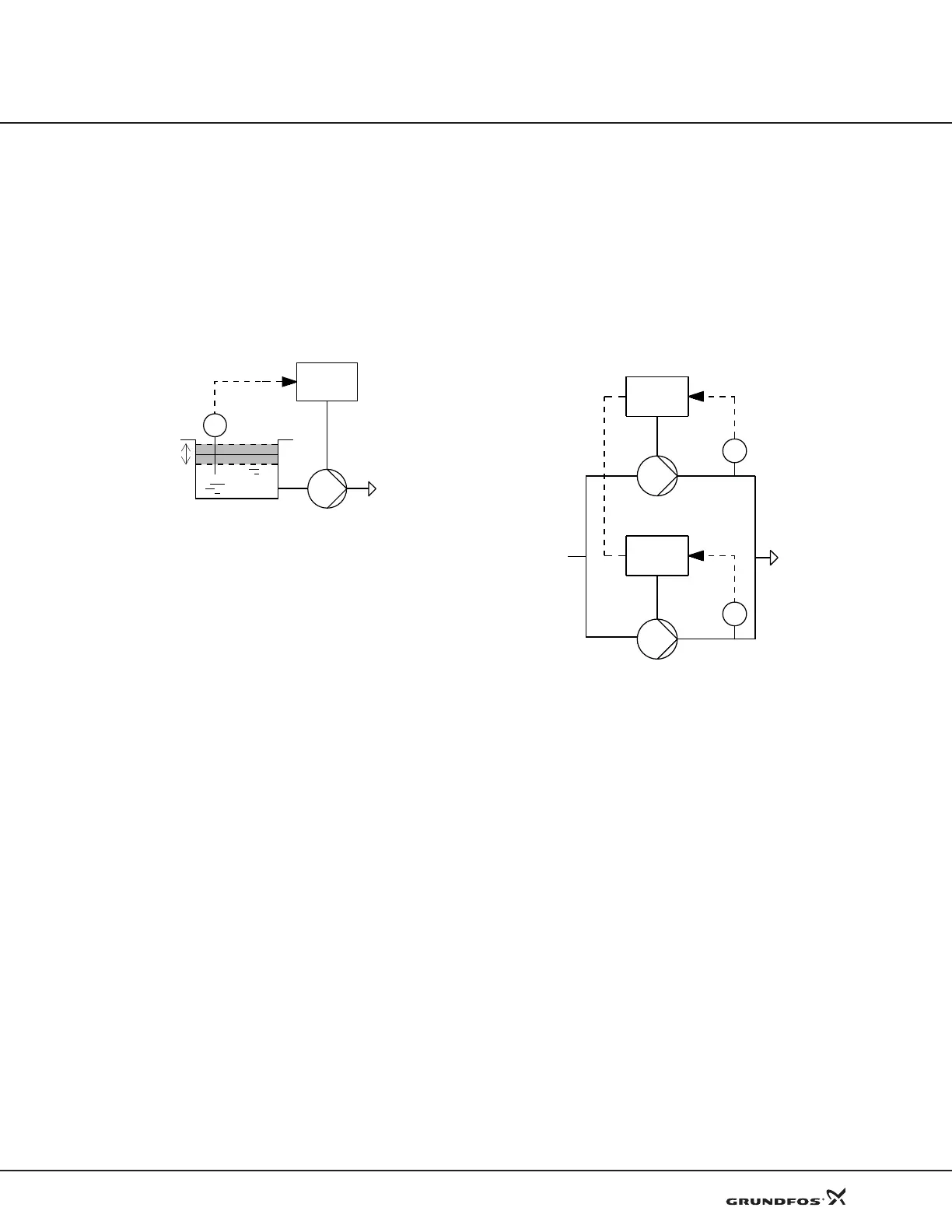

Duty/standby

The built-in duty/standby function applies to two pumps

connected in parallel to ensure reliability of supply. See

fig. 26.

Fig. 26 Two pumps connected in parallel and controlled

via GENIbus

These are the primary purposes of the function:

• To let one pump run at a time.

• To start the standby pump if the duty pump stops

due to an alarm.

• To alternate the pumps at least every 24 hours.

Description

The two pumps are electrically connected by means of

th

e GENIbus interface. Each pump must be connected

to its own CUE and sensor.

Note: The t

wo pumps running duty/standby in this way

cannot use the GENIbus interface for remote communi-

cation.

The function is activated via the control panel.

Operating mode

The two pumps use their own local operating mode. For

inst

ance, pump 1 can operate in Normal mode, and

pump 2 can operate in Max. mode.

Control mode

Both pumps must have the same control mode.

TM03 8809 2607

Start level

ΔH

Stop level

CUE

L

TM04 0368 0608

CUE

p

CUE

p

Loading...

Loading...