Installation

Grundfos CUE

35

The lengths stated apply to the motor cable.

Motor cable

Use a shielded/armored motor cable to comply with

EMC emission specifications (or install the cable in a

metal conduit). Keep the motor cable as short as possi-

ble to reduce the noise level and leakage currents.

C

onnect the motor cable shield/armor to both the

decoupling plate of the adjustable frequency drive and

to the metal of the motor. (Same applies to both ends of

the metal conduit if used instead of a shield.)

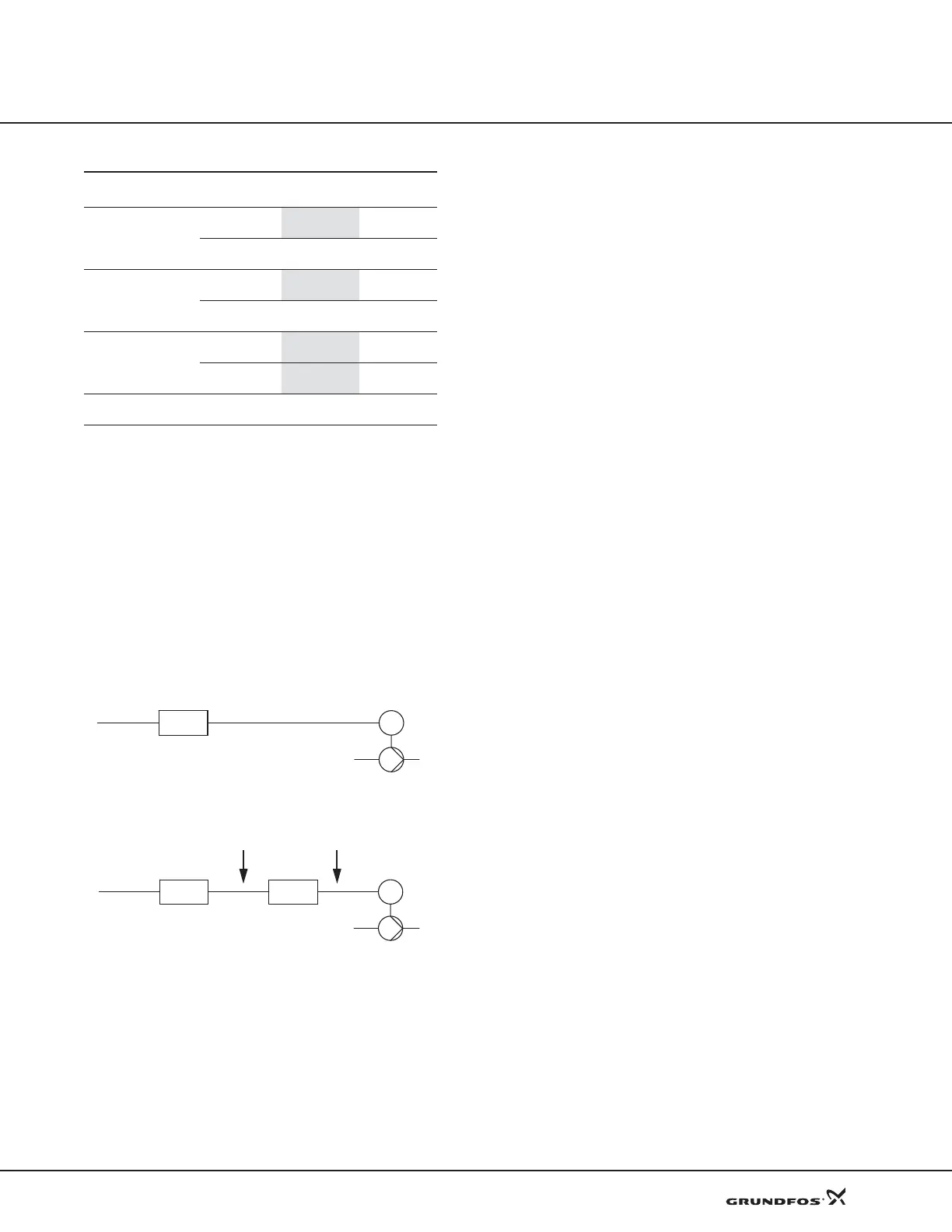

Fig. 41 Example of installation without filter

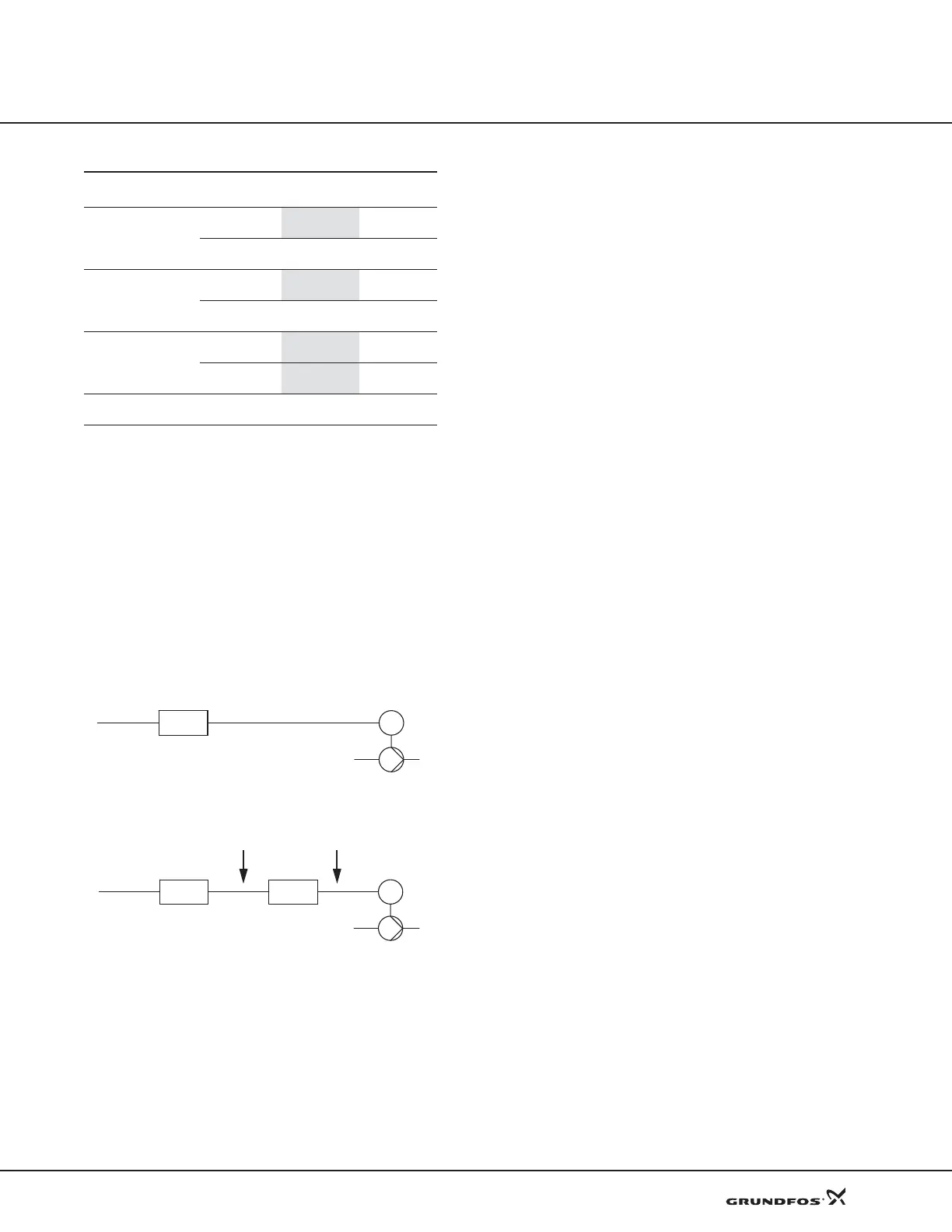

Fig. 42 Example of installation with filter. The cable be-

tween the CUE and filter must be short

EMC-correct installation

This section gives guidelines for good practice when

installing the CUE. Follow these guidelines to meet EN

61800-3, first environment.

• Use only motor and signal cables with a braided

m

etal screen in applications without output filter.

• There are no special requirements to supply cables,

ap

art from local requirements.

• Leave the screen as close to the connecting termi-

nals as possible. See fig. 43.

• Avoid terminating the screen by twisting the ends.

See fig.

44. Use cable clamps or EMC screwed ca-

ble entries instead.

• Connect the screen to frame at both ends for both

motor and signal cables. See fig. 45. If the controller

has no cable clamps, connect only the screen to the

CUE. See fig. 46.

• Avoid unscreened motor and signal cables in elec-

trical cabinets with frequency converters.

• Make the motor cable as short as possible in appli-

cations without output filter to limit the noise level

and mini

mize leakage currents.

• Screws for frame connections must always be tight-

ened whether a cable is connected or not.

• Keep main cables, motor cables and signal cables

separated in the installation, if possible.

Other installation methods may give similar EMC

r

esults if the above guidelines for good practice are fol-

lowed.

Pump type

Typical shaft

power P2

dU/dt filter

Sine-wave

filter

SP, BM, BMB with

380 V motor and up

Up to 10 Hp

–

0-1000 ft

(0-300 m)

15 Hp and up

0-500 ft

(0-150 m)

500-1000 ft

(150-300 m)

Other pumps, noise

reduction

Up to 10 Hp

–

0-1000 ft

(0-300 m)

15 Hp and up

0-500 ft

(0-150 m)

500-1000 ft

(150-300 m)

Other pumps, higher

noise reduction

Up to 10 Hp

–

0-1000 ft

(0-300 m)

15 Hp and up

–

0-1000 ft

(0-300 m)

Pumps with 690 V

motor

All

0-500 ft

(0-150 m)

500-1000 ft

(150-300 m)

TM03 8802 2507TM03 8803 2507

CUE

Mains cable,

unscreened

Motor cable,

screened

M

CUE

Filter

Mains cable,

unscreened

Motor cable,

screened

M

Loading...

Loading...