English (GB)

6

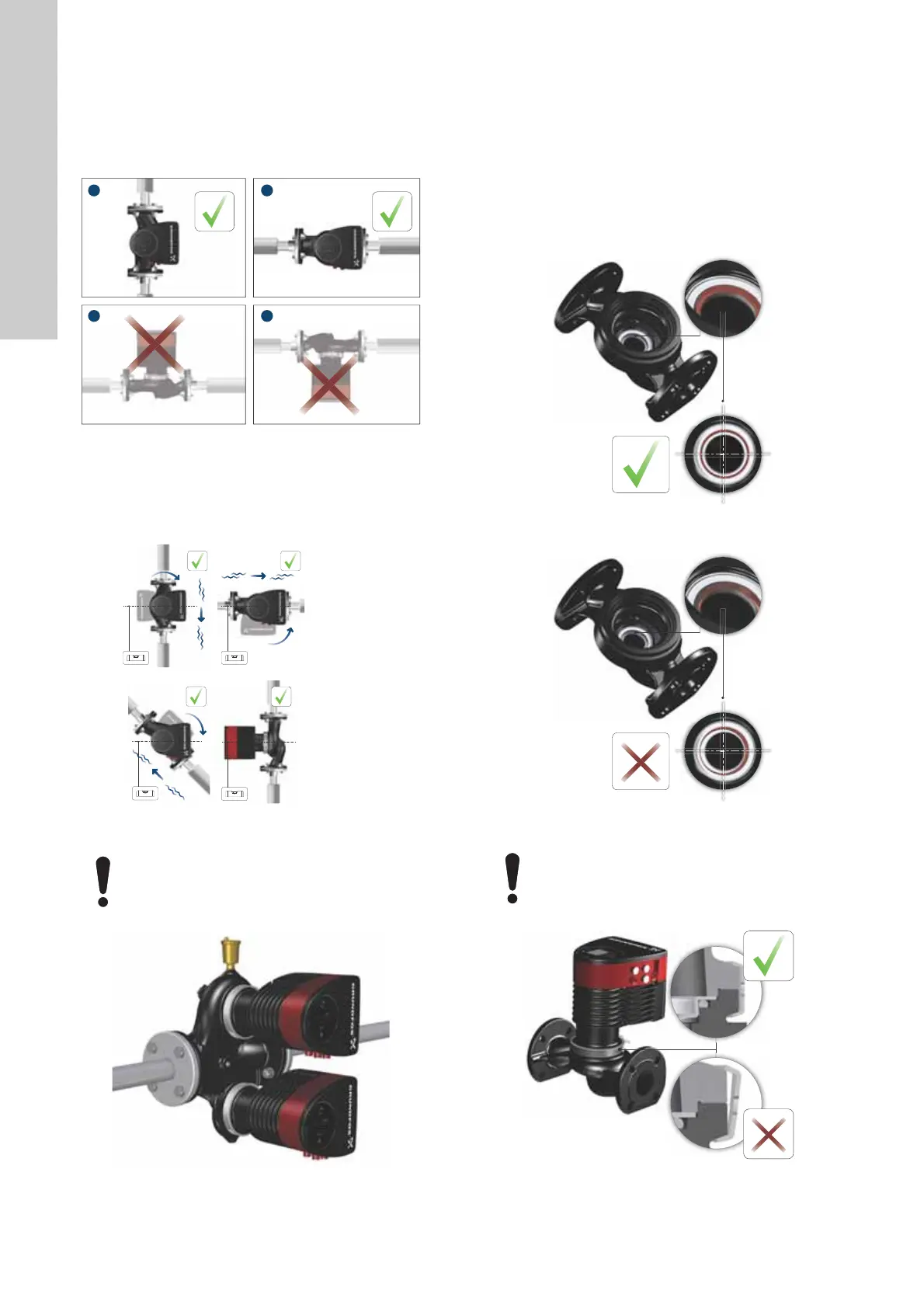

3.3.1 Pump positions

Always install the pump with horizontal motor shaft.

• Pump installed correctly in a vertical pipe. See fig. 6, pos. A.

• Pump installed correctly in a horizontal pipe. See fig. 6, pos. B.

• Do not install the pump with vertical motor shaft. See fig. 6,

pos. C and D.

Fig. 6 Pump installed with horizontal motor shaft

3.3.2 Control box positions

To ensure adequate cooling, make sure that the control box is in

horizontal position with the Grundfos logo in vertical position. See

fig. 7.

Fig. 7 Pump with control box in horizontal position

Fig. 8 Automatic vent

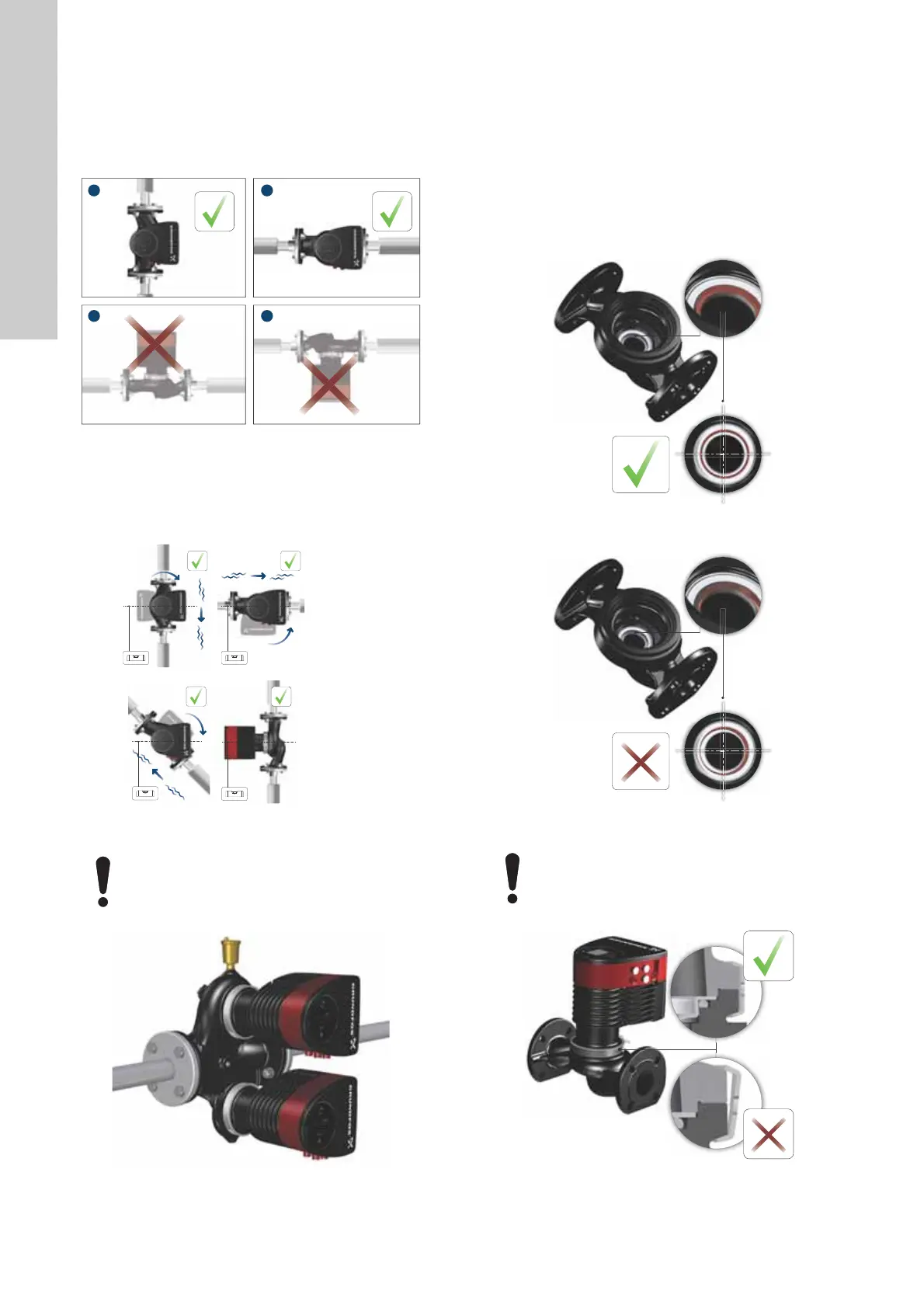

3.3.3 Pump head position

If you remove the pump head before installing the pump in the

pipes, pay special attention when fitting the pump head to the

pump housing:

1. Visually check that the floating ring in the sealing system is

centred. See figs 9 and 10.

2. Gently lower the pump head with rotor shaft and impeller into

the pump housing.

3. Make sure that the contact face of the pump housing and that

of the pump head are in contact before you tighten the clamp.

See fig. 11.

Fig. 9 Correctly centred sealing system

Fig. 10 Incorrectly centred sealing system

Fig. 11 Fitting the pump head to the pump housing

TM05 5518 3016TM05 5522 3016

Fit twin-head pumps installed in horizontal pipes with

an automatic air vent, Rp 1/4, in the upper part of the

pump housing. See fig. 8.

TM05 6062 3016

TM05 6650 3016TM05 6651 3016

Check the position of the clamp before you tighten it.

Incorrect position of the clamp will cause leakage

from the pump and damage the hydraulic parts in the

pump head. See fig. 11.

TM05 5837 3016

Loading...

Loading...