6.5 STO installation, optional

DANGER

Exposure to high pressure or toxic liquids

Death or serious personal injury

‐ Failure to remove the jumper will disable the STO

function and the motor might not stop as intended and

can cause severe injury or death.

‐ Failure to use safety-monitoring relay compliant with

Category 3 /PL "d", ISO 13849-1 or SIL 2, EN 62061

and IEC 61508. Perform a functional test every 12

months to ensure that the system works properly.

To enable the integrated STO, follow these steps:

1. Remove the jumper wire between control terminals 37 and 12

or 13. Cutting or breaking the jumper is not sufficient to avoid

short-circuiting.

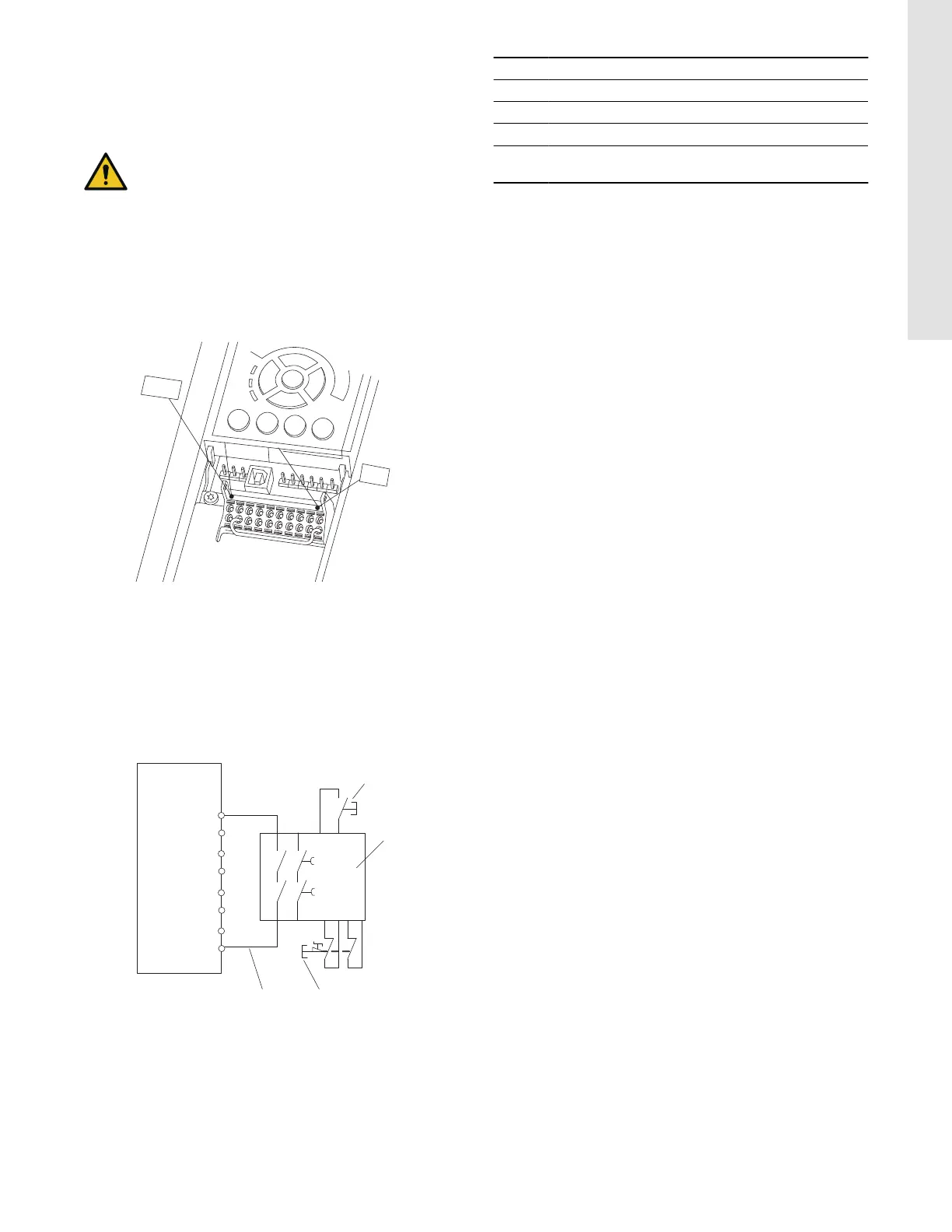

TM074595

Remove jumper

2. Connect an external safety-monitoring relay via a NO safety

function to terminal 37 (STO) and either terminal 12 or 13, 24 V

DC.

Select and apply the components in the safety control system

appropriately to achieve the desired level of operational safety.

Before integrating and using STO in an installation, carry out a

thorough risk analysis on the installation to determine whether the

STO functionality and safety levels are appropriate and sufficient.

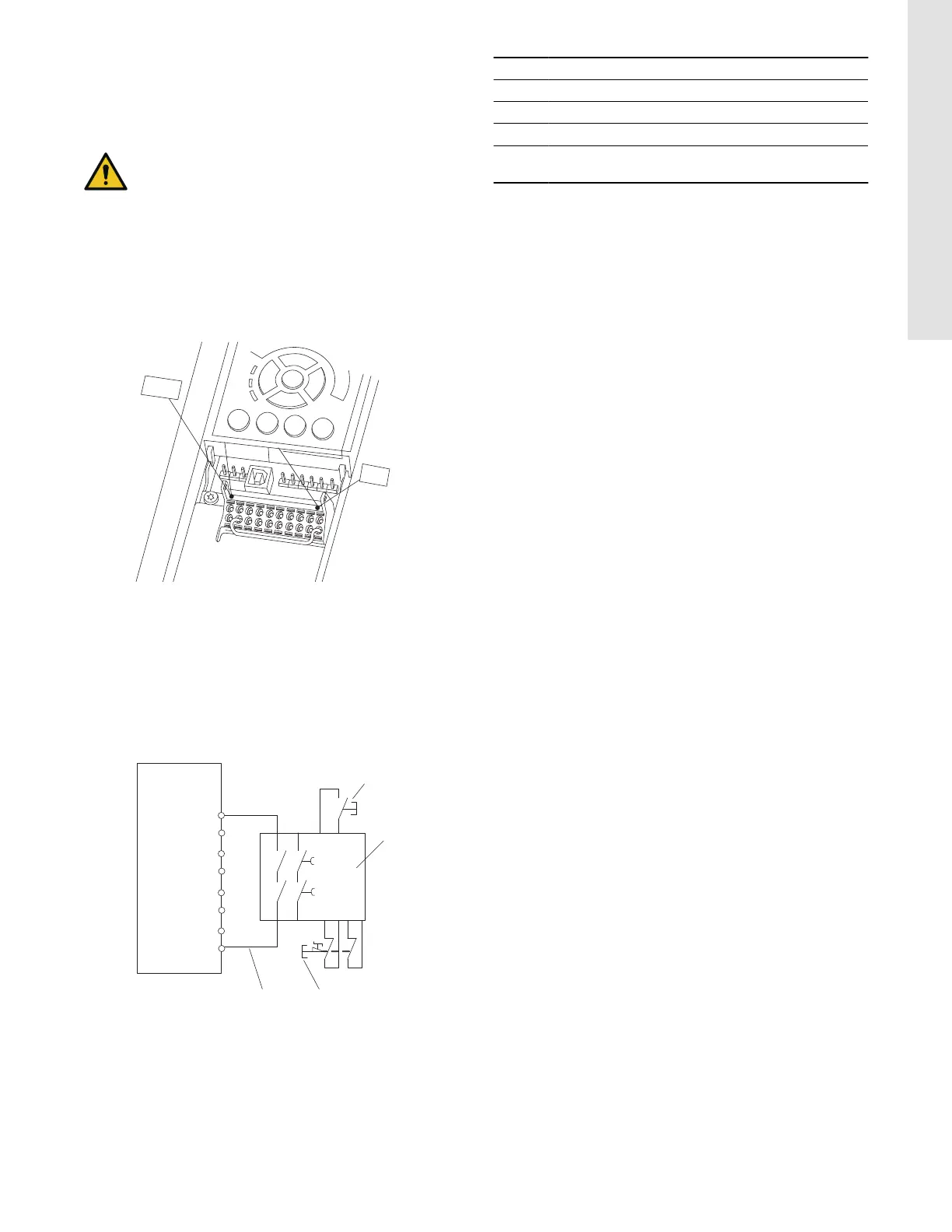

TM074594

STO wiring

Pos. Description

1 Reset button

2 Safety relay (category 3, PL d or SIL2)

3 Emergency stop button

4

Short-circuit protected cable if the product is not installed

inside an IP54 cabinet.

13

English (US)

Loading...

Loading...