Value Explanation

Measurement evalu-

ation

0 mA

Cable break /

Sensor fault

Change the WIO sen-

sor.

3.8 mA

No oil in oil

chamber

Do the test when the

oil chamber is empty.

4-10 mA

Normal opera-

tion

Do the test when the

oil chamber is full.

>10 mA

Water in oil, pos-

sible leak

Check the seals, pos-

sible water leak.

Related information

8.3 Oil check and change

8.4 Inspection and adjustment of the impeller

clearance

8.3 Oil check and change

The oil chamber is filled with oil acting as a lubricant

and a coolant for both mechanical seals.

Check the oil in the oil chamber every

3000 operating hours or at least once a

year, or if the shaft seal is changed.

Low oil level may indicate that the upper mechanical

shaft seal is defective. Contact an authorised service

workshop for further overhaul of the pump and repair,

if required.

Lack of oil may cause overheating and

damage to the mechanical shaft seals.

The WIO sensor in the oil chamber trips

the alarm if the oil quality or quantity is in-

adequate, or there is no oil in the oil cham-

ber.

Oil auto-ignition temperature must be

above 250 °C. Use any of the following:

• Elf Performance Polytraffic 10W-40

• Total Rubia Polytraffic 10W-40

• Pennzoil SAE 10W-40.

Range

Oil quantity

Installation type

S [litres] C, D and H [litres]

50 2.6 1.9

54 3.5 2.5

58 4.6 3.8

62 9.0 7.1

66 12.5 9.2

70 12.4 9.0

The oil in the oil chamber can be changed while the

pump is in either horizontal or vertical position.

However; it is recommended to carry out the oil

change while the pump is in a horizontal position.

This way, it is easier to drain all the used oil out of the

chamber.

Horizontal position

Proceed as follows:

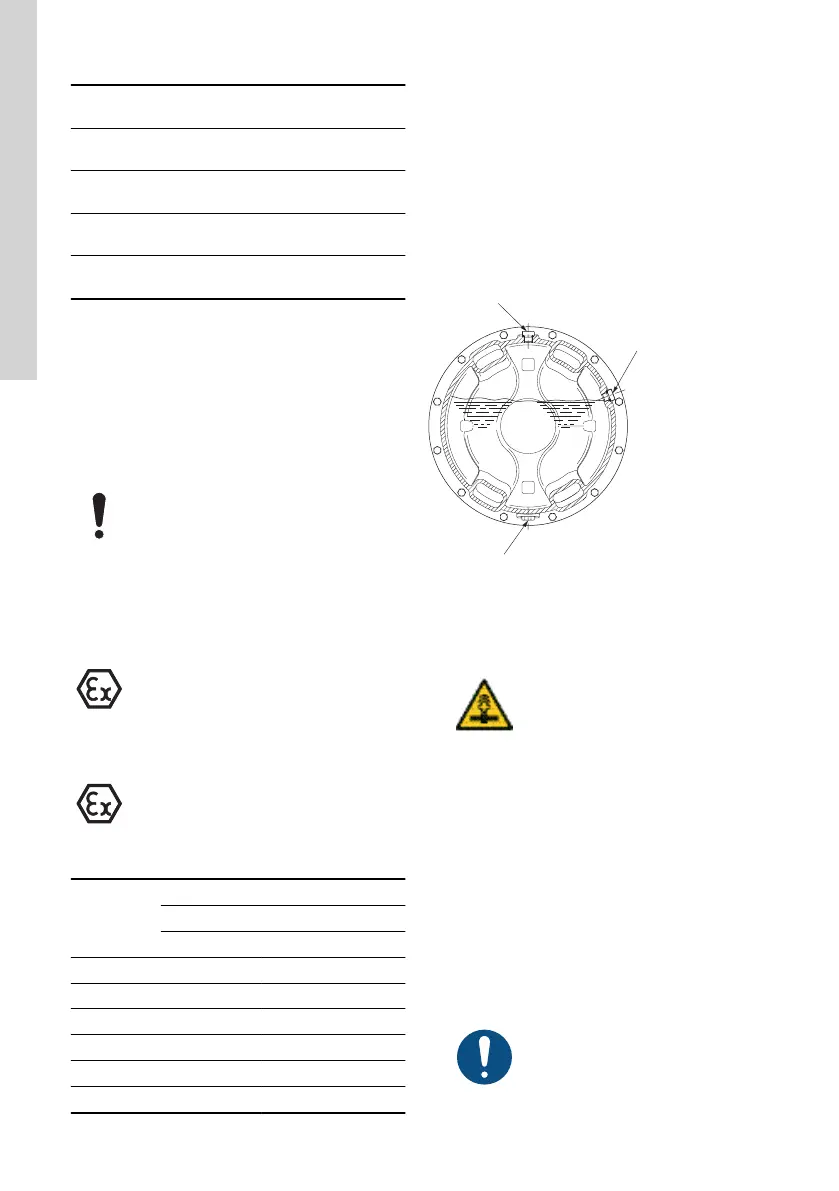

1. Place the pump in a position that inspection screw

A is pointing upwards.

TM031628

Pump with inspection screw A upwards

CAUTION

Pressurised system

Minor or moderate personal injury

‐ The oil chamber may be under

pressure. Loosen the screws care-

fully and do not remove them until

the pressure has been fully re-

lieved.

2. Loosen and remove screw A.

3. Remove screw B and check the oil level.

4. Inspect the oil coming out of the motor. If the

colour is greyish white, the oil may contain water.

If the oil contains water, the shaft seal is defective

and must be replaced. Oil not containing water

can be reused.

5. If the oil needs to be changed, place a clean

container under the pump to collect all the

drained-off oil.

6. Remove screw C and allow all the oil to drain from

the chamber into the container. Emulsified oil

must be changed and disposed of.

Used oil must be disposed of in ac-

cordance with local regulations.

34

English (GB)

Loading...

Loading...