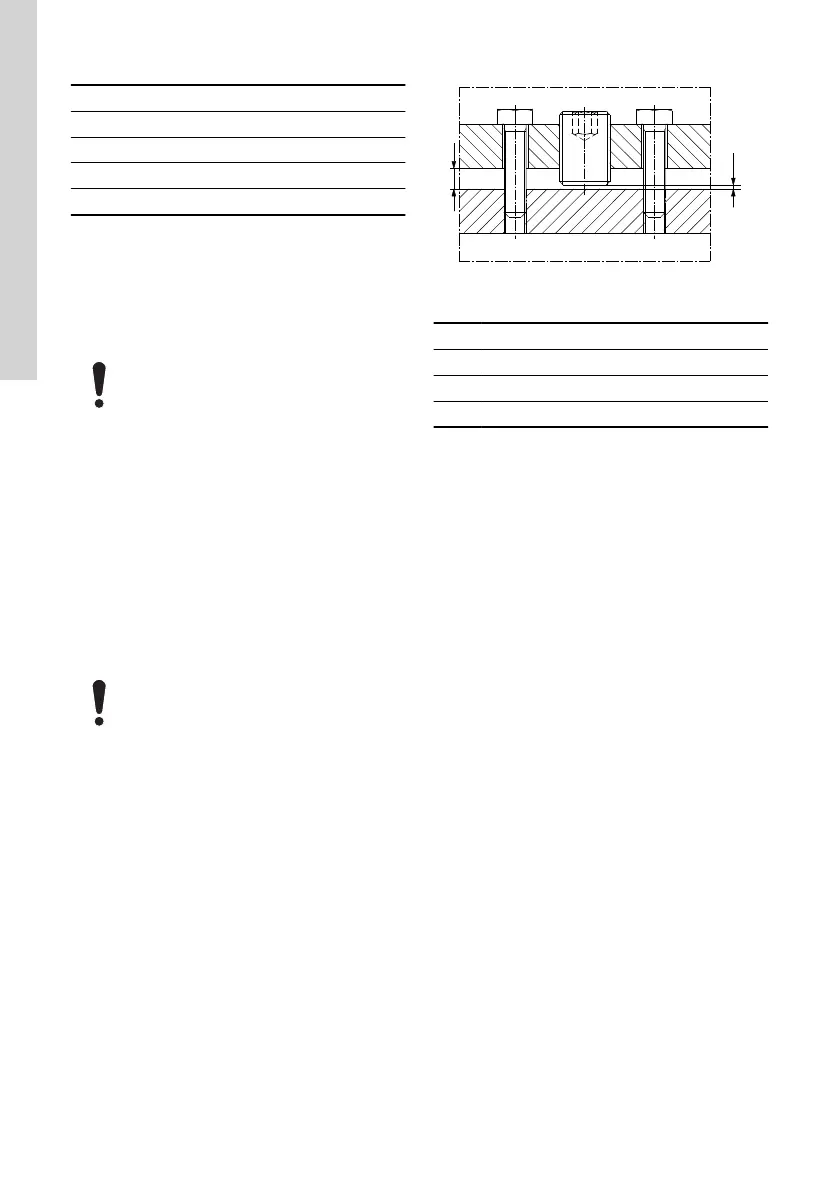

Pos. Description

1 0.7

2 Set screw

3 Fastening screw

4 Fastening screw

8.4.2 Dry-installed pumps, installation types D

and H

Depending on the pump range, there are two ways to

set the impeller clearance. Method 1 is for range

50-54 and method 2 is for range 58-70.

Method 1

Do not use undue force when tightening

the fastening screws as this may damage

the bearings. The movement is usually 1

to 3 mm.

1. Loosen the set screws by two full turns for each.

2. Close the impeller clearance by lightly tightening

the fastening screws diagonally until the impeller

reaches the pump housing.

3. Loosen the fastening screws to make a 0.7 mm

gap under the heads of the fastening screws. See

fig. Impeller clearance adjustment.

4. Tighten the set screws tightly.

5. Tighten the fastening screws diagonally.

Method 2

Do not use undue force when tightening

the fastening screws as this may damage

the bearings. The movement is usually 1

to 3 mm.

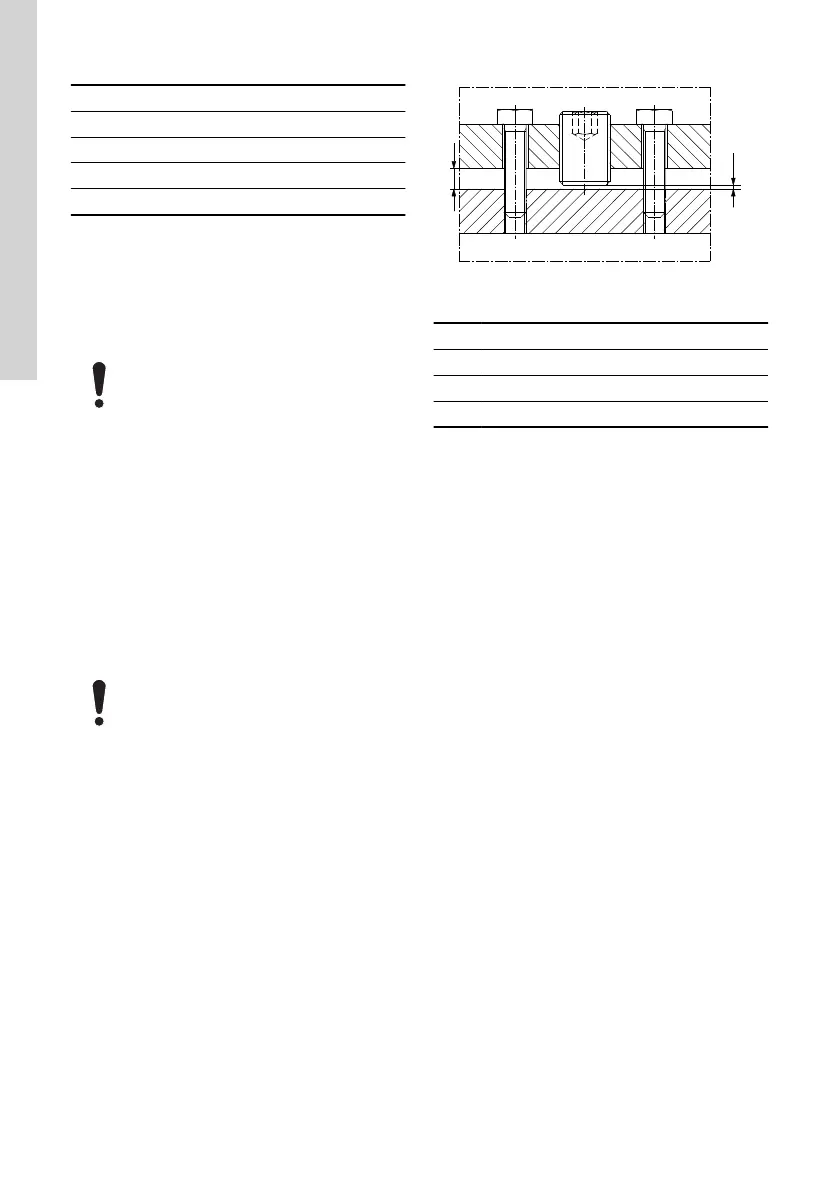

1. Loosen the six fastening screws and close the

impeller clearance by tightening the three set

screws. Tighten the screws diagonally to move

the inlet cover evenly.

2. Measure the distance "L" between the inlet cover

and pump housing at three points next to the set

screws, using feeler gauges or calipers, then note

the distance.

3. Loosen the set screws and draw back the inlet

cover between 0.5 and 0.9 mm using the six

fastening screws (approximately one 270° turn of

an M12 fastening screw) and the distance "L" as

reference. See fig. Impeller clearance adjustment.

4. Tighten all set screws and check that the distance

"L" at the three reference points is stable at the

new value.

TM051915

Impeller clearance adjustment

Pos. Description

1 Set screw

2 Fastening screw

H 0.5 - 0.9

Related information

8.4.1 Submersible pumps, installation types S, C

and ST

8.5 Pump cleaning and inspection

Clean the pumps at regular intervals. In case of wet-

installed pumps, lift the pumps out of the pit and clean

them on site. Hose down the pump externally using a

high-pressure jet cleaner at a maximum of 100 bars.

Remove caked dirt from the motor to ensure proper

heat conductivity. A mild detergent approved for

disposal into the sewage system can be used. The

pumps can be scrubbed, using a soft brush, if

necessary.

Visual inspection of the pump must include the

following:

• Search for cracks or other external damage.

• Check the lifting bracket and lifting chain for wear

and corrosion.

• Make sure the motor cables are not damaged.

• Inspect visible parts of the cable entries for

cracks.

• Check if the cables are firmly connected to the

motor top cover.

• Check all visible screws for self-loosening and

tighten, if necessary.

The pumps are fitted with a vent valve at the top of

the cooling jacket. The valve may be removed and

cleaned, if necessary. Clean the vent hole before

refitting the valve.

8.6

Motor cables

Use only suitable and manufacturer-approved cables.

36

English (GB)

Loading...

Loading...