7. Replace the O-rings, refit screw C and tighten

securely. Fill the oil chamber with oil to the correct

level. Refit screws A and B and tighten them

securely.

Vertical position

Proceed as follows:

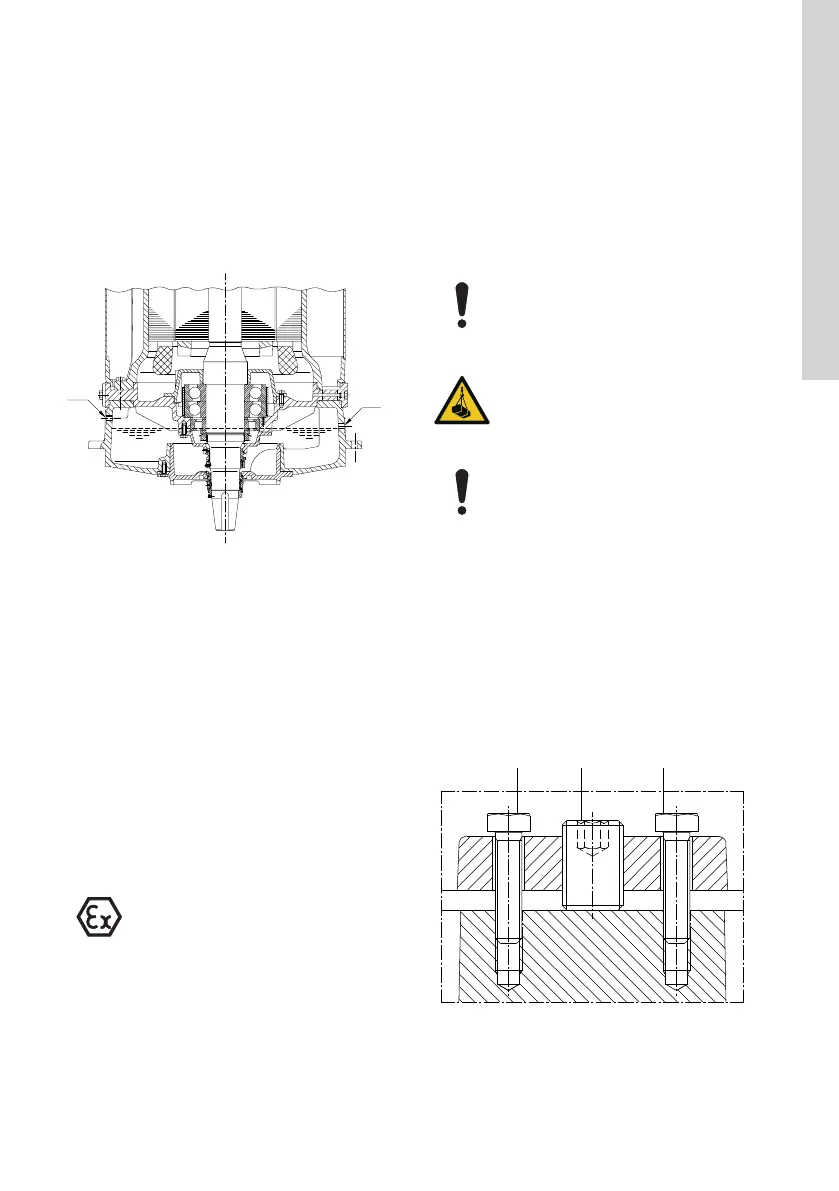

1. Identify the screws A, B and C. See fig. Pump with

inspection screw A upwards.

TM024005

Oil level of a vertical pump

2. Use screw B for indication of the oil level in the oil

chamber. See fig. Oil level of a vertical pump.

3. When the pump is vertical, the oil has to be

pumped out of the oil chamber. Use a suction

pump with a flexible suction hose that can be

inserted deep into the oil chamber.

4. Pump out the oil using all the screw holes in turns

to reach all sections of the oil chamber. Collect the

drained oil in a clean container.

5. Replace the O-rings, refit screw C and tighten

securely. Fill the oil chamber with oil to the correct

level. Refit screws A and B and tighten them

securely.

8.4

Inspection and adjustment of the

impeller clearance

The impeller clearance must be set to 0.7

mm ± 0.2 mm. It must be checked at least

3 different points.

The correct axial clearance is 0.7 mm ± 0.2 mm.

Reset the clearance if it is 0.7 mm or more. The

method for resetting the clearance is different for

submersible pumps, installation types S, C and ST,

and for dry-installed pumps, installation types D and

H.

8.4.1

Submersible pumps, installation types S, C

and ST

Submersible pumps have a separate, adjustable

pump inlet cover, which may be shaped as an inlet

bell. Locate the six fastening screws of the inlet cover

and the three set screws.

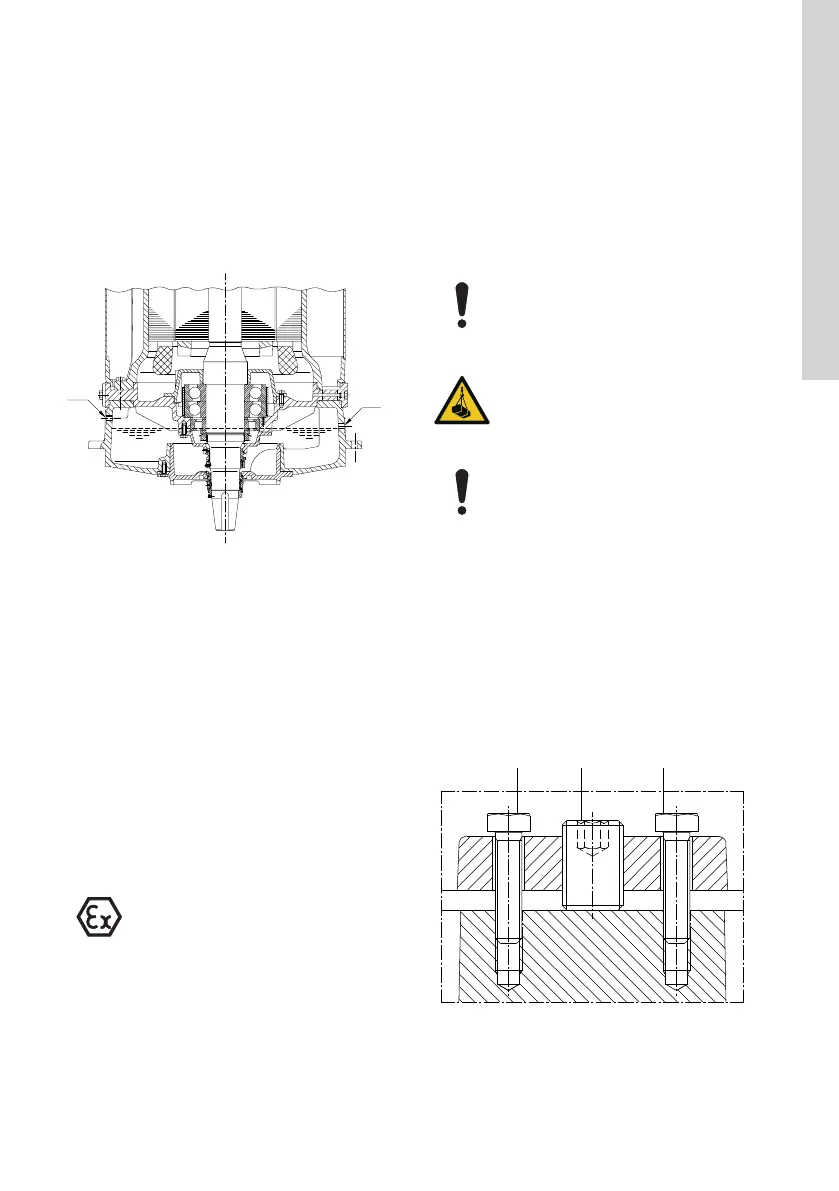

Use a feeler gauge to check the clearance between

the impeller and the inlet cover all around the

perimeter of the inlet opening. See fig. Impeller

clearance adjustment.

Do not use force when tightening the fas-

tening screws as this may damage the

bearings. The movement is usually 1 to 3

mm.

DANGER

Overhead load

Death or serious personal injury

‐ Never work under a pump when it is

hanging from a crane.

Before adjusting the clearance, clean the

gap between the impeller and the inlet

cover.

1. Loosen the set screws by two full turns for each.

2. Close the impeller clearance by lightly tightening

the fastening screws diagonally until the impeller

reaches the pump housing.

3. Loosen the fastening screws to make a 0.7 mm

gap under the heads of the fastening screws. See

fig. Impeller clearance adjustment.

4. Tighten the set screws tightly.

5. Tighten the fastening screws diagonally.

TM051916

Impeller clearance adjustment

35

English (GB)

Loading...

Loading...