6.3 Motor protection

The pump incorporates current- and temperature-

dependent motor protection. If the pump is blocked or

otherwise overloaded, the built-in thermal switch will

cut out. When the motor has cooled sufficiently, it will

restart automatically.

No external motor protection is required.

7. Starting up the product

Do not turn on the power supply until the

pump has been filled with liquid.

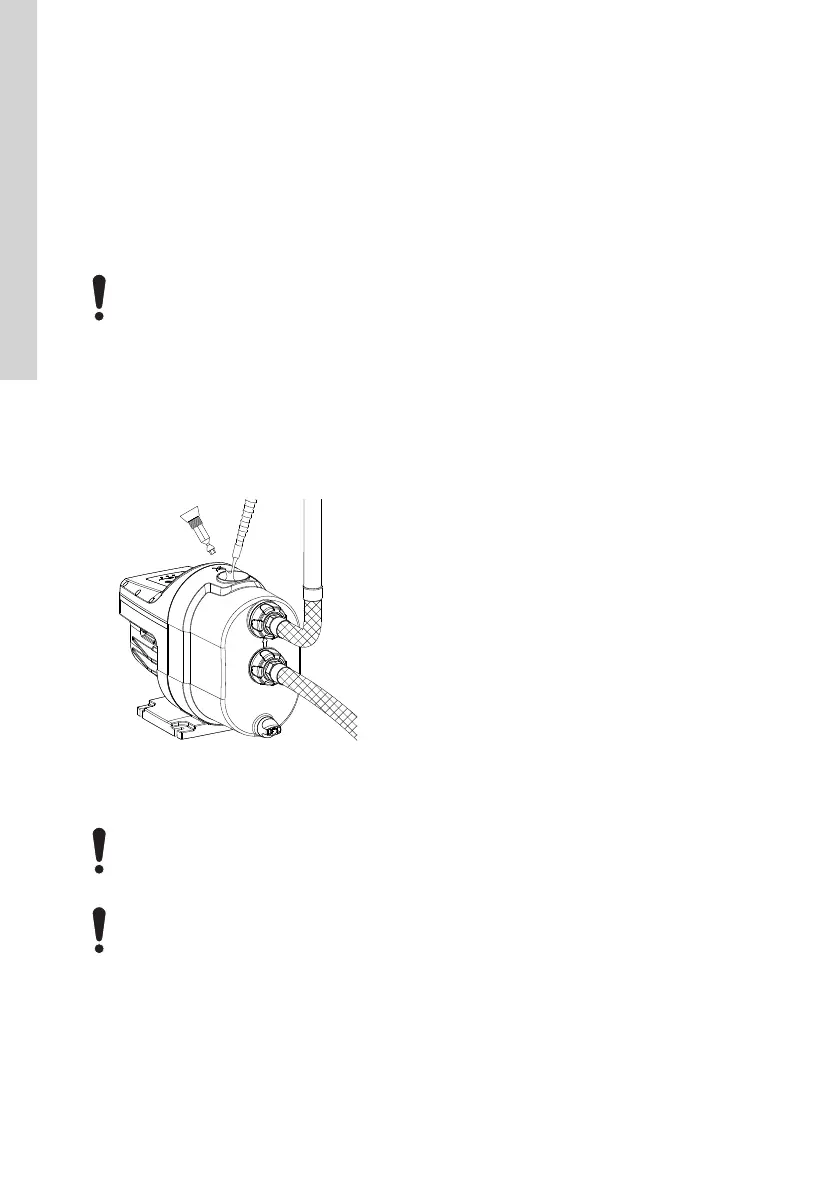

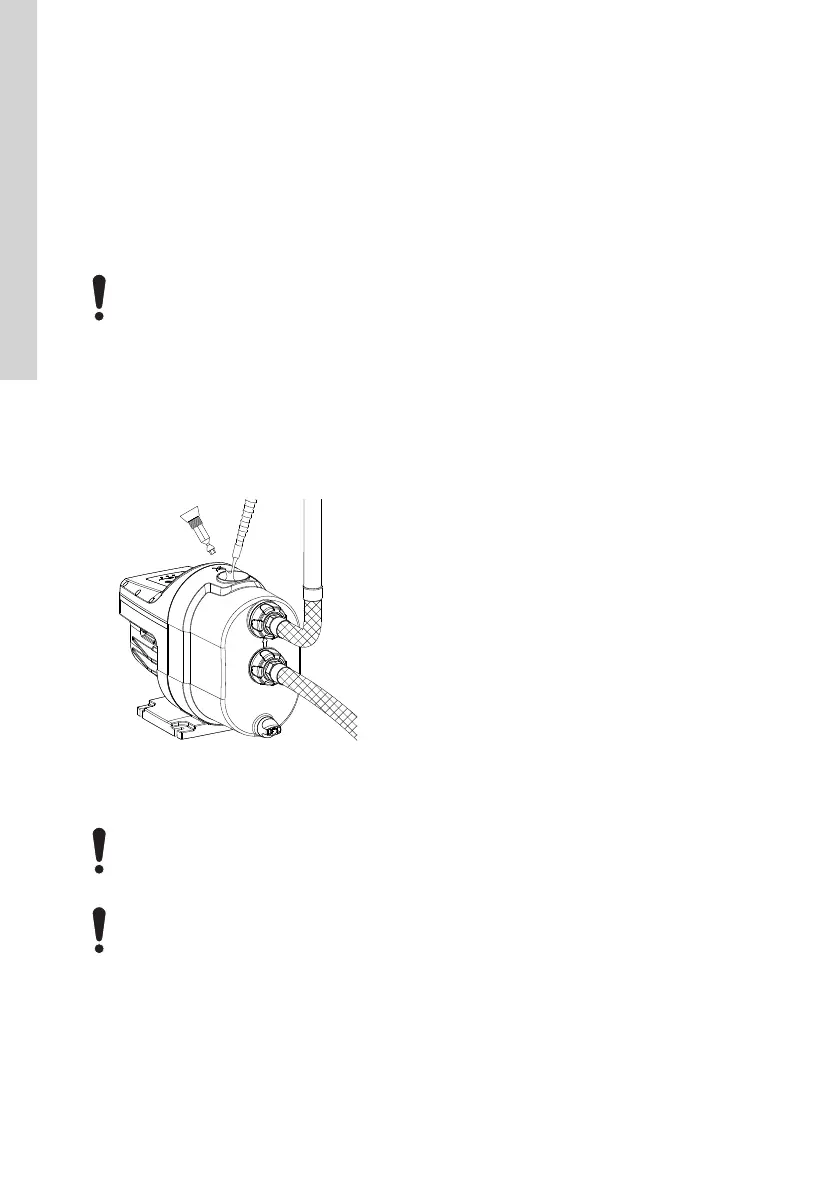

7.1 Priming the product

1. Unscrew the priming plug and pour at least 1.7

litres (0.45 gallons) of water into the pump

housing.

2. Screw the priming plug on again.

Example:

TM075342

Priming the pump

If the suction depth exceeds 6 m (20 ft), it

may be necessary to prime the pump more

than once.

Always tighten priming and drain plugs by

hand.

7.2 Starting up the pump

After installing and priming, follow the following steps

to start up the pump.

1. Prime the pump according to the priming

instructions.

2. Open all isolating valves.

3. Open the tapping point that is the highest or

furthest away from the pump to let out air trapped

in the system.

4. Turn on the pump's power supply. All the

symbols on the operating panel will light up

briefly. The Stop icon remains on.

5. Press the Start/Stop button to start the pump. If

there is a suction lift, it may take up to five

minutes before the pump delivers water

depending on the length and diameter of the inlet

pipe.

6. When the water flows through the tapping point

without air, close the tapping point. The pump will

stop after approx. 10 seconds.

7. The startup is now completed, and the pump is

ready for operation.

7.3 Operation

7.3.1 Normal operation

When water is consumed in the water supply system,

the pump starts if the starting conditions of the pump

are fulfilled. This happens, for example, when a tap is

opened, making the pressure in the system drop.

The pump stops when the consumption stops, i.e.

when the tap is closed.

7.3.1.1 Starting and stopping conditions

Starting conditions

The pump starts when at least one of the following

conditions is fulfilled:

• The flow is higher than Qmin (1.5 l/min).

• The pressure is lower than pstart.

Stopping conditions

The pump stops with a time delay of 10 seconds

when both of the following conditions are fulfilled:

• The flow is lower than Qmin (1.5 l/min).

• The pressure is higher than pstart.

The pstart values are shown in Technical data.

7.4

Shaft seal run-in

The shaft seal faces are lubricated by the pumped

liquid. A slight leakage from the shaft seal of up to 10

ml per day or 8 to 10 drops per hour may occur.

Under normal conditions, the leaking liquid will

evaporate. As a result, no leakage will be detected.

When the pump is started for the first time, or when

the shaft seal has been replaced, a certain run-in

period is required before the leakage is reduced to an

acceptable level. The time required for this depends

on the operating conditions, that is, every time the

operating conditions change, a new run-in period will

be started.

14

English (GB)

Loading...

Loading...