English (GB)

4

2.2.1 Shaft seal

Mechanical shaft seal with assembly length to EN 12756.

The following variants are available as standard:

2.2.2 Codes for shaft seal

The positions (1) - (4) cover four pieces of information about the

shaft seal:

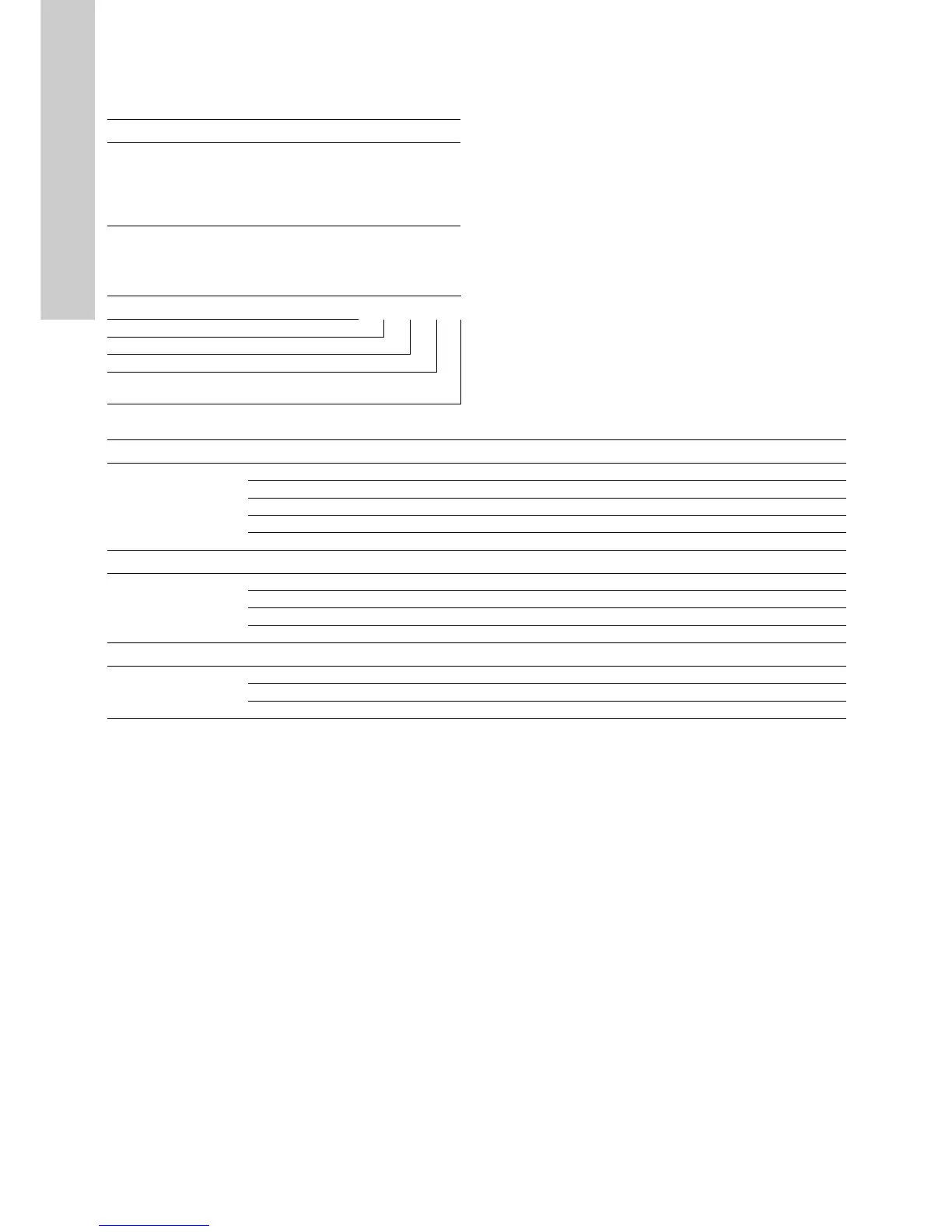

The following table explains the positions (1), (2), (3) and (4).

Pump Shaft diameter Variant code

TP Series 300,

flange

∅ 28

∅ 38

∅ 48

∅ 55

∅ 60

BAQE

BQQE

GQQE

Example (1) (2) (3) (4)

Grundfos type designation

Material, rotating seal face

Material, stationary seat

Material, secondary seal and other rubber and plastic parts,

excluding the neck ring

Position Type Short description of seal

(1)

A O-ring seal with fixed driver

B Rubber bellows seal

D O-ring seal, balanced

G Bellows seal, type B, with reduced seal faces

R O-ring seal, type A, with reduced seal faces

Position Type Material

(2) and (3)

A Carbon, metal-impregnated (antimony)

B Carbon, resin-impregnated

U Tungsten carbide

Q Silicon carbide

Position Type Material

(4)

EEPDM

FFXM

V FKM

Loading...

Loading...