English (GB)

10

The operating voltage and frequency are marked on

the pump nameplate. Make sure that the motor is

suitable for the power supply on which it will be used.

Single-phase standard motors incorporate a thermal

switch and require no additional motor protection.

Three-phase motors must be connected to a motor

starter.

Motors of 3 kW and up incorporate thermistors

(PTC). The thermistors are designed according to

DIN 44082.

The electrical connection should be carried out as

shown in the diagram inside the terminal box cover.

The motors of twin-head pumps are to be connected

separately.

6.1 Frequency converter operation

Grundfos motors:

All three-phase Grundfos motors from frame size 90

and up can be connected to a frequency converter.

The connection of a frequency converter will often

have the effect that the motor insulation system is

loaded more and that the motor will be more noisy

than during normal operation. In addition, large

motors are loaded by bearing currents caused by the

frequency converter.

In the case of frequency converter operation, the

following should be considered:

• In 2-, 4- and 6-pole motors of 45 kW and up, one

of the motor bearings should be electrically

isolated to prevent damaging currents from

passing through the motor bearings.

• In the case of noise-critical applications, the

motor noise can be reduced by fitting a dU/dt

filter between the motor and the frequency

converter. In particularly noise-critical

applications, it is recommended to fit a sinusoidal

filter.

• The length of the cable between motor and

frequency converter affects the motor load. It

should therefore be checked that the cable length

meets the specifications laid down by the

frequency converter supplier.

• For supply voltages between 500 and 690 V,

either a dU/dt filter should be fitted to reduce

voltage peaks or a motor with reinforced

insulation should be used.

• For supply voltages of 690 V, a motor with

reinforced insulation should be used and a dU/dt

filter should be fitted.

6.1.1 Other motor makes than Grundfos

Contact Grundfos or the motor manufacturer.

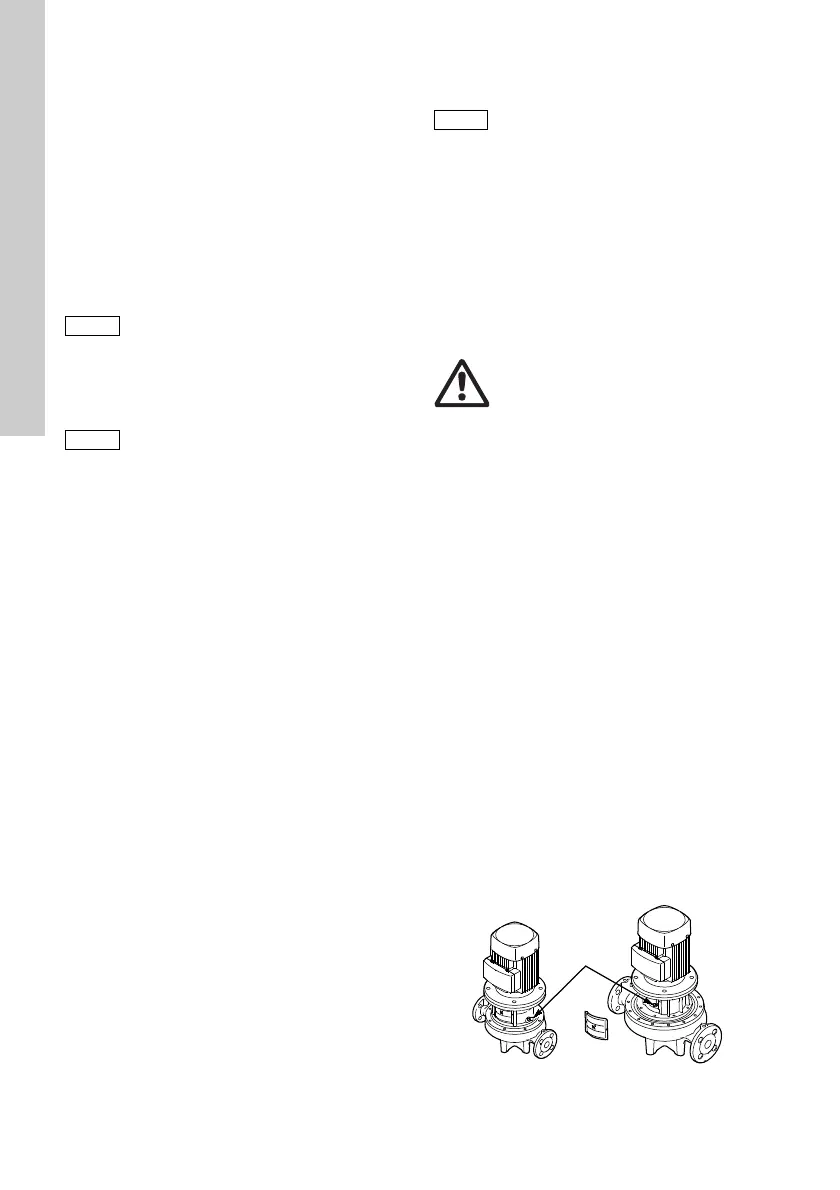

7. Start-up

7.1 Priming

Closed systems or open systems where the

liquid level is above the pump inlet:

1. Close the discharge isolating valve and loosen

the air vent screw in the motor stool. See fig. 13.

2. Slowly open the isolating valve in the suction

pipe until a steady stream of liquid runs out of the

vent hole.

3. Tighten the air vent screw and completely open

the isolating valve(s).

Open systems where the liquid level is below the

pump inlet:

The suction pipe and the pump must be filled with

liquid and vented before the pump is started.

1. Close the discharge isolating valve and open the

isolating valve in the suction pipe.

2. Loosen the air vent screw. See fig. 13.

3. Remove the plug from one of the pump flanges,

depending on the pump location.

4. Pour liquid through the priming port until the

suction pipe and the pump are filled with liquid.

5. Replace the plug and tighten securely.

6. Tighten the air vent screw.

The suction pipe can to some extent be filled with

liquid and vented before it is connected to the pump.

A priming device can also be installed before the

pump.

Fig. 13 Position of air vent screw

Do not start the pump until it has been

filled with liquid and vented.

Motors types MEZ 63, MG 71 and MG 80

for supply voltages up to and including

440 V (see motor nameplate) must be

protected against voltage peaks higher

than 650 V between the supply

terminals.

Do not start the pump until it has been

filled with liquid and vented. To ensure

correct venting, the vent screw should

point upwards.

Warning

Pay attention to the direction of the

vent hole, and ensure that the escaping

liquid does not cause injury to persons

or damage to the motor or other

components.

In hot-liquid installations, pay special

attention to the risk of injury caused by

scalding hot liquid.

In cold-liquid installations, pay special

attention to the risk of injury caused by

the cold liquid.

TM03 8126 0507

Loading...

Loading...