English (GB)

12

Lubrication:

The bearings of motors up to 11 kW are greased for

life and require no lubrication.

The bearings of motors of 11 kW and up must be

greased in accordance with the indications on the

motor nameplate.

The motor should be lubricated with a lithium-based

grease meeting the following specifications:

• NLGI grade 2 or 3.

• Viscosity of basic oil: 70 to 150 cSt at 40 °C

(~ +104 °F).

• Temperature range: –30 °C (~ –22 °F) to 140 °C

(~ +284 °F) during continuous operation.

8.3 Service

If Grundfos is requested to service the pump,

Grundfos must be contacted with details about the

pumped liquid, etc. before the pump is returned for

service. Otherwise Grundfos can refuse to accept

the pump for service.

Possible costs of returning the pump are paid by

the customer.

8.4 Shaft adjustment

If the motor has been removed during installation or

for repair of the pump, the pump shaft must be

adjusted after the motor has been replaced.

8.4.1 Pumps with two-part coupling

Pumps Series 100 and 200

Make sure that the shaft pin is fitted in the pump

shaft.

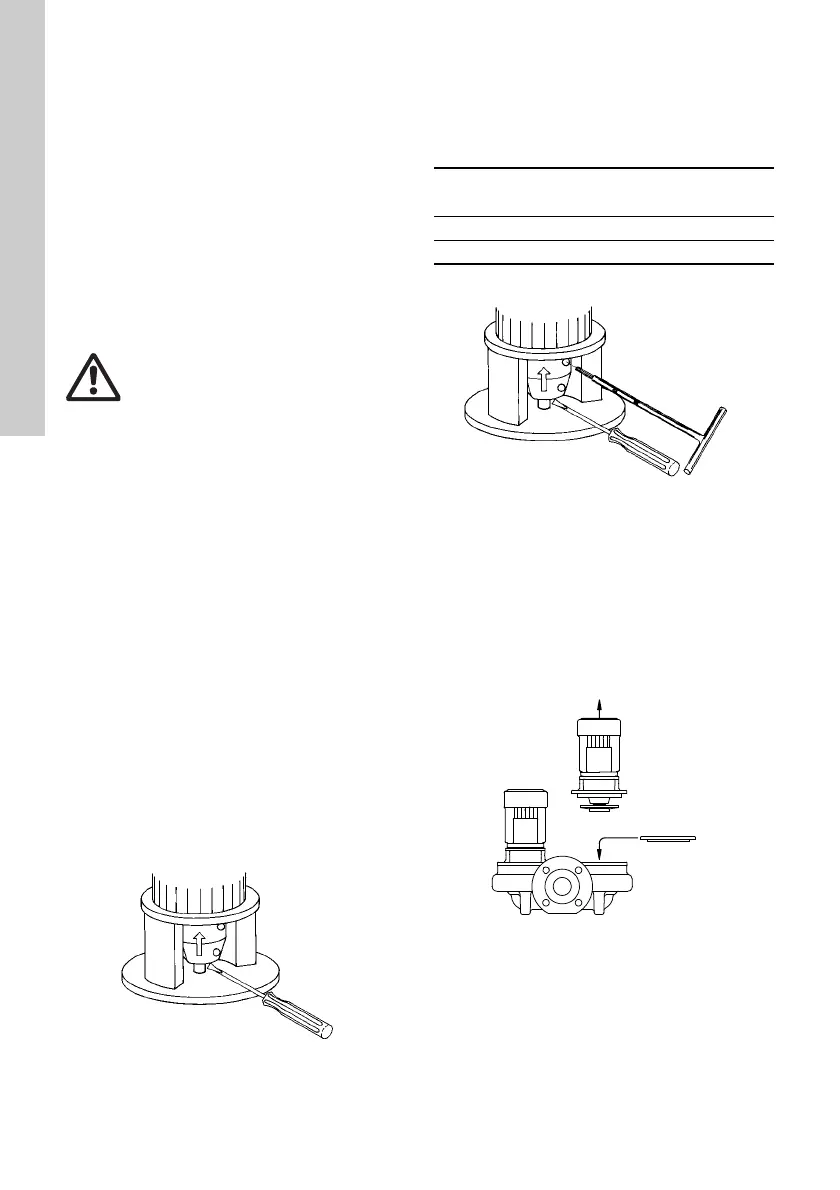

Adjust the pump shaft as follows:

1. Remove the coupling guards using a screwdriver.

2. Fit the hexagon socket head screws in the

coupling and leave loose.

3. Raise the coupling and the pump shaft as far as

possible (towards the motor) with a screwdriver

or a similar tool so that the pump and motor

shafts touch each other. See fig. 14.

Fig. 14 Raising the coupling and the pump shaft

4. Tighten the hexagon socket head screws in the

coupling to 5 Nm (0.5 kpm).

5. Check that the gaps either side of the coupling

halves are equal.

6. Tighten the screws two and two (one side at a

time) to the torque stated below. See fig. 15.

7. Fit the coupling guards.

Fig. 15 Tightening the screws

8.4.2 Pumps with integral shaft/coupling

For pumps with integral shaft/coupling, it is advisable

not to remove the motor. If the motor has been

removed, it is necessary to remove the motor stool in

order to refit the motor correctly. Otherwise the shaft

seal may be damaged.

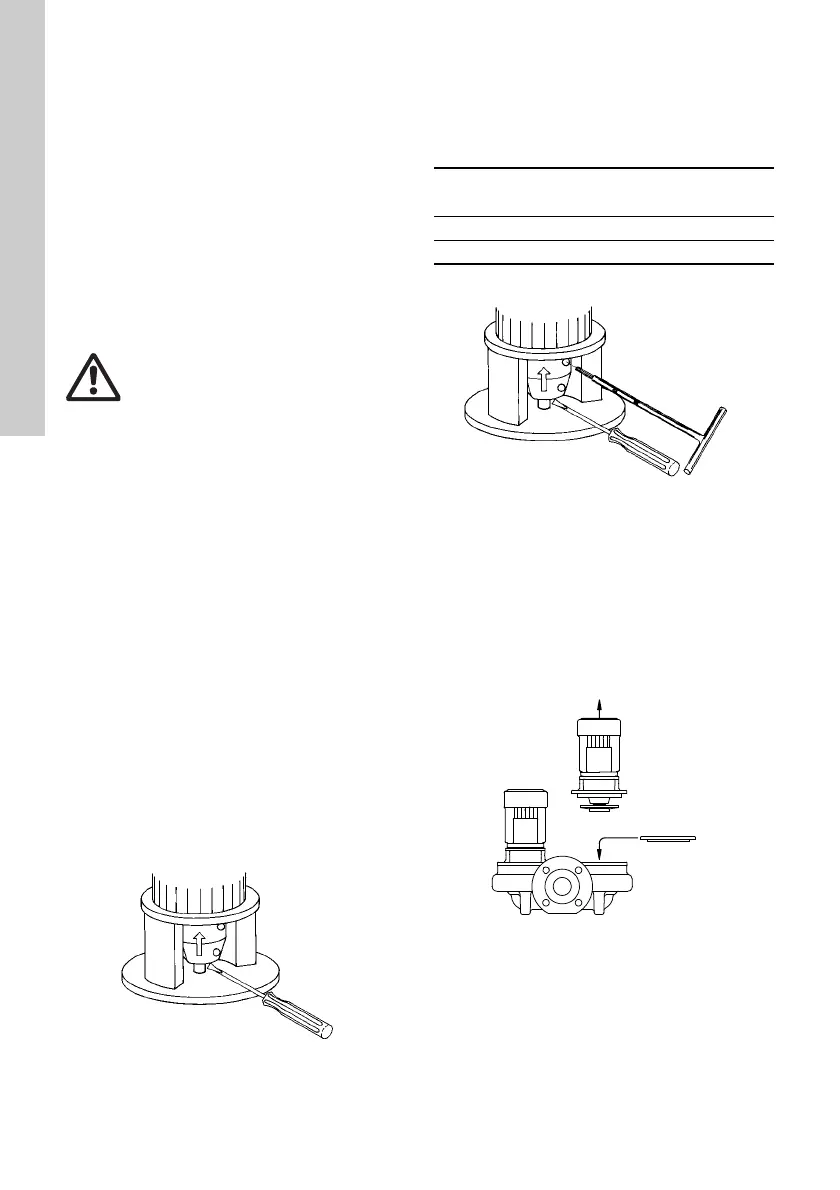

8.5 Blanking flanges

For twin-head pumps, a blanking flange with a pump

housing gasket is available. See fig. 16.

Fig. 16 Fitting the blanking flange

If one pump requires service, the blanking flange is

fitted to allow the other pump to continue operating.

Warning

If the pump has been used for a liquid

which is injurious to health or toxic, the

pump will be classified as

contaminated.

TM00 6415 3695

Hexagon socket head

screw

Torque

M6 x 20 13 Nm (1.3 kpm)

M8 x 25 31 Nm (3.1 kpm)

TM00 6416 3695 TM00 6360 3495

Loading...

Loading...