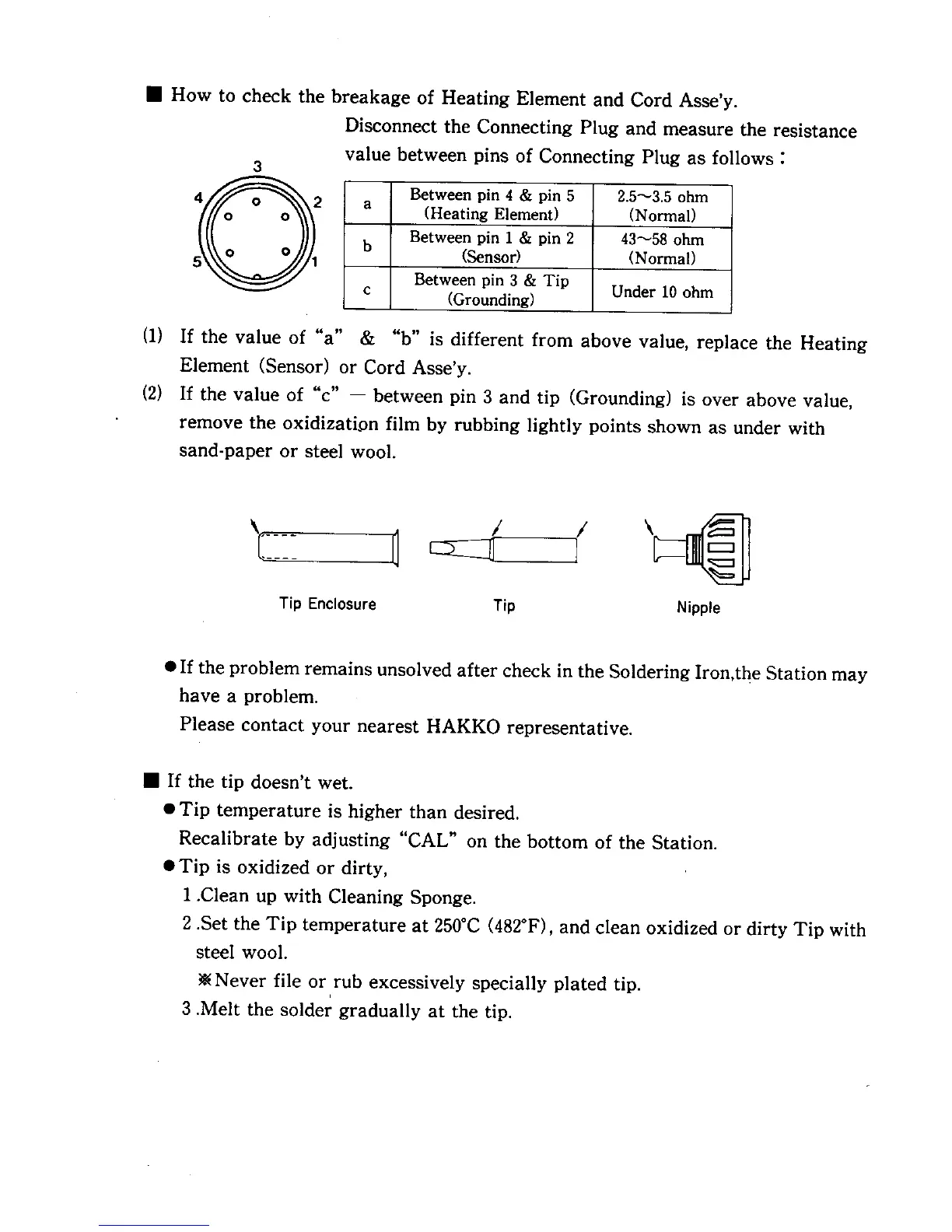

• How to check the breakage of Heating Element and Cord Asse'y.

Disconnect the Connecting Plug and measure the resistance

3

value between pins of Connecting Plug as follows :

Between pin 4 & pin 5 2.5_-3.5 ohm

a (Heating Element) (Normal)

Between pin 1 & pin 2 43_58 ohm

b (Sensor) (Normal)

Between pin 3 & Tip Under 10 ohm

c (Grounding)

(I) If the value of "a" & "b" is different from above value, replace the Heating

Element (Sensor) or Cord Asse'y.

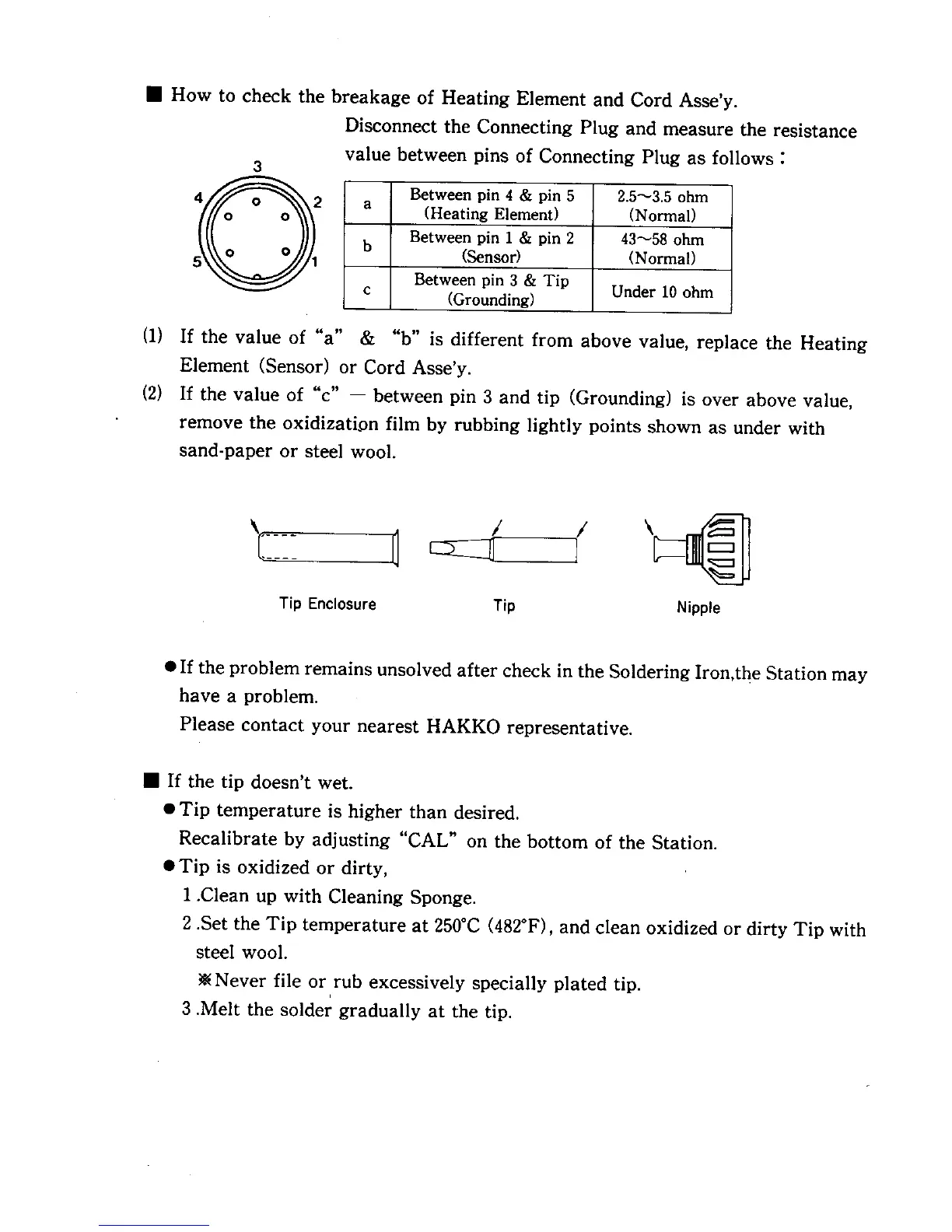

(2) If the value of "c" -- between pin 3 and tip (Grounding) is over above value,

remove the oxidizatipn film by rubbing lightly points shown as under with

sand-paper or steel wool.

Tip Enclosure Tip Nipple

• If the problem remains unsolved after check in the Soldering Iron,the Station may

have a problem.

Please contact your nearest HAKKO representative.

• If the tip doesn't wet.

• Tip temperature is higher than desired.

Recalibrate by adjusting "CAL" on the bottom of the Station.

• Tip is oxidized or dirty,

1 .Clean up with Cleaning Sponge.

2 .Set the Tip temperature at 250°C (482°F), and clean oxidized or dirty Tip with

steel wool.

• Never file or rub excessively specially plated tip.

i

3 .Melt the solder gradually at the tip.

Loading...

Loading...