37

32

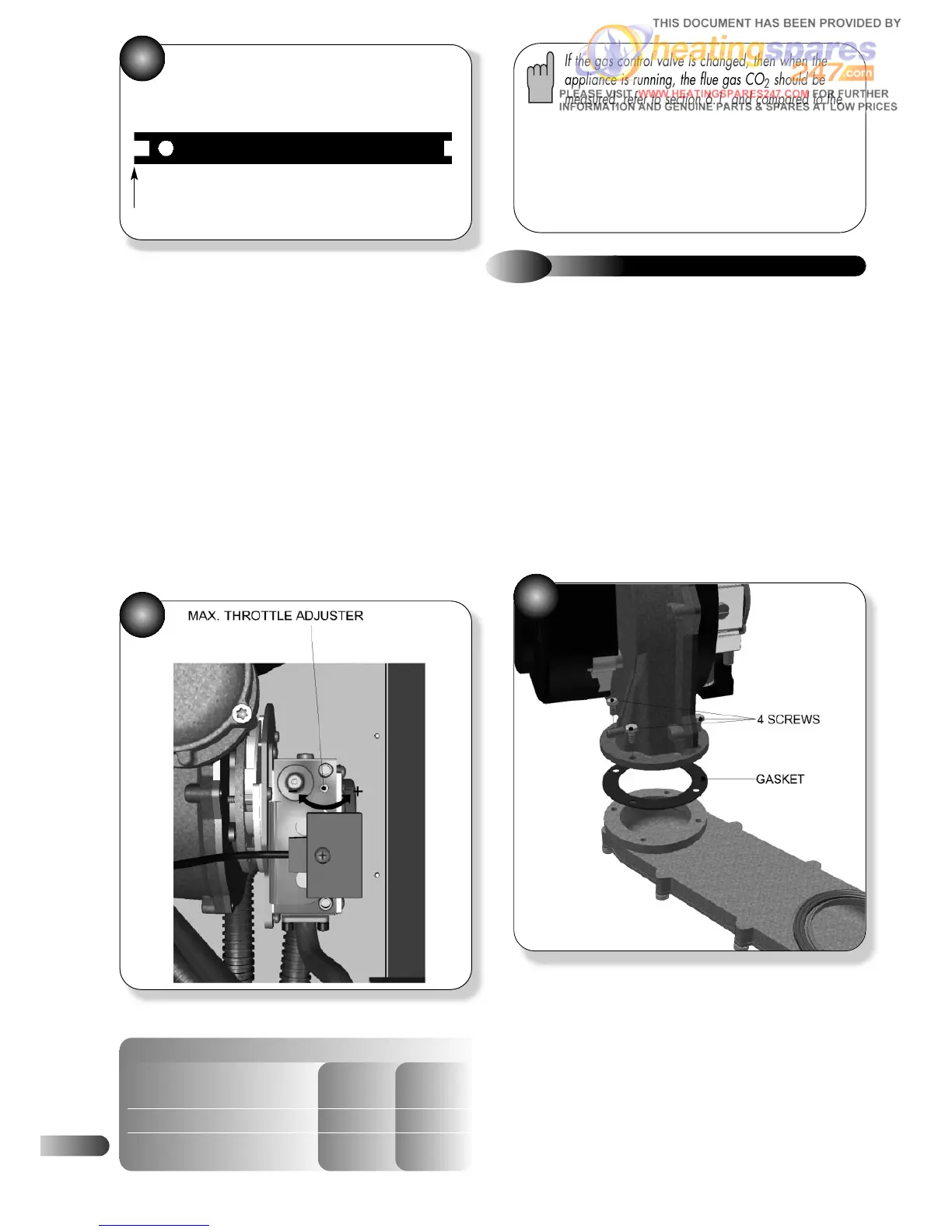

e) Check that the CO

2

reading is within the required values shown

below in the table. If it is outside the required values adjust the

CO

2

by turning the max throttle adjuster as follows:-

Anti-clockwise to increase CO

2

Clockwise to decrease CO

2

f) Once the CO

2

is stable it is necessary to check it again at

maximum CH input.

g) Turn the CH control knob back to normal operation mode and

within 3 seconds back to ‘Service mode’. The fan speed will now

increase.

h) Check CO

2

at max CH heat input. The CO

2

value should be

between 0.2% & 0.8% greater than the measured CO

2

value at

minimum CH heat input (Combustion set-up table).

i) If the CO

2

at max CH heat input requires adjusting, steps b to f

above must be repeated.

38

Combustion Set up table

Ace HE24 Ace HE30

CO

2

value (min CH input) 7.9 – 8.5 % 8.3 – 8.9 %

CO

2

value (max CH input) (Case off) 8.8 – 9.2 % 8.8 – 9.2 %

X (measured from valve body 4.5mm 4.5mm

to top of screw)

If the gas control valve is changed, then when the

appliance is running, the flue gas CO

2

should be

measured, refer to section 6.1, and compared to the

values stated section 2.3. If the measured value does

not correspond to the Performance Data, then contact:

Halstead Boilers Ltd. Service Help line: 01926 834834.

Always seal the gas valve adjustment screw with paint

after adjustment

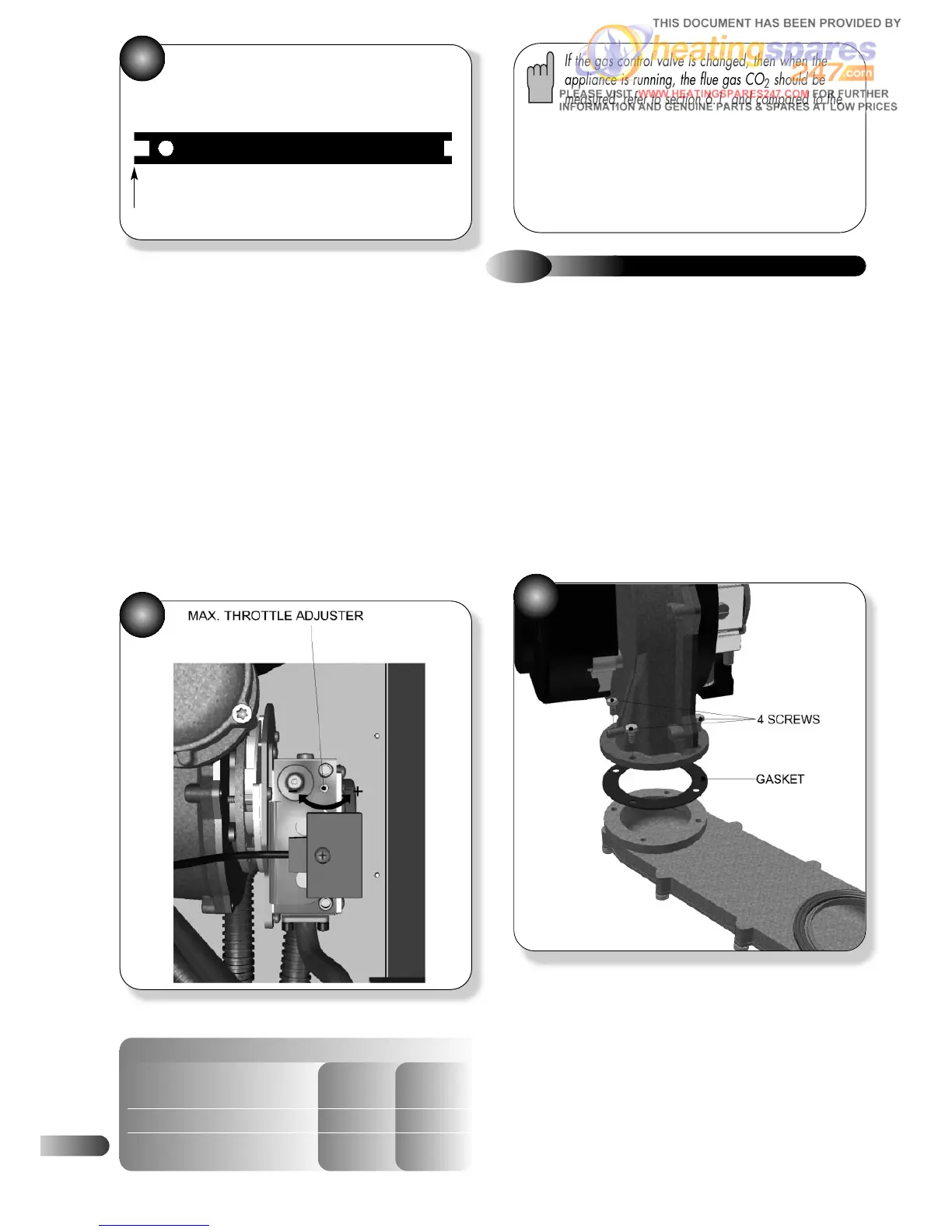

9.4

FAN

Refer to Figures 36 & 39

a)

Ensure supply voltage is isolated, and that the gas supply is

isolated.

b) Remove the gas control valve, fan & burner assembly; refer to

section 6.2.

c) Remove the gas control valve; refer to section 9.3.

d) Unscrew the three screws holding the gas valve mounting

plate, remove plate; refer to Figure 36.

e) Unscrew the four screws holding the fan to the burner

manifold, and remove fan; refer to Figure 39.

f) Attach and secure the replacement fan, replace the gasket.

g) Re-assemble in reverse order; ensure that all joints and seals

are correctly re-fitted.

39

THROTTLE ADJUSTMENT TOOL

Use this end for Nat Gas

Loading...

Loading...