38

8

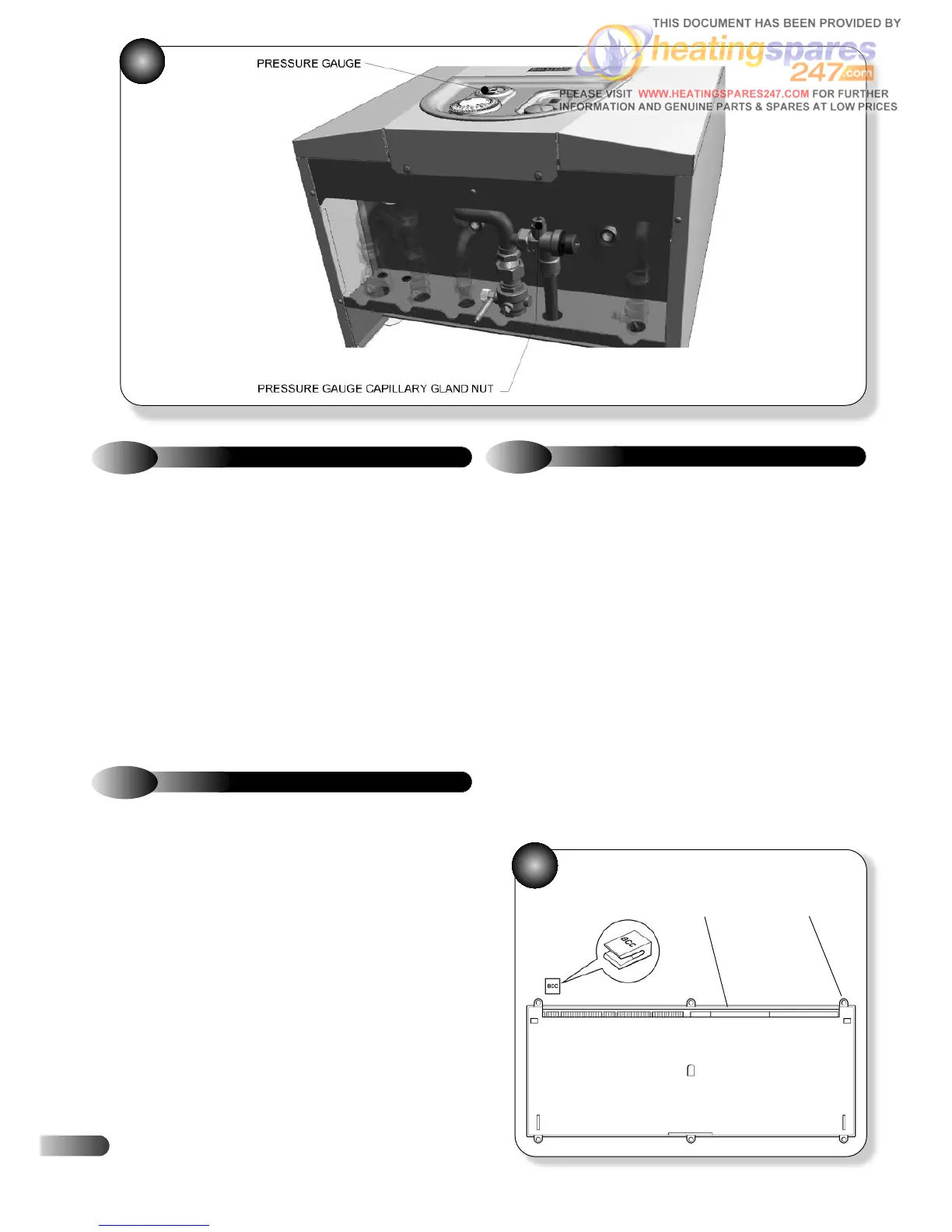

51

9.18

PRESSURE GAUGE

Refer to Figure 51

a)

Ensure supply voltage is isolated.

b) Drain down the appliance; refer to section 9.24.

c) Disconnect the pressure gauge capillary gland nut from the

pressure relief valve.

d) Having removed the decorative front and lowered the control

fascia disengage the pressure gauge from the fascia panel, and

remove the gauge.

e) Fit the new pressure gauge and re-assemble in reverse order.

f) Open the isolating cocks and vent air from the system using the

manual air vent. Re-pressurise the system as necessary and check for

water leaks.

9.19

AUTO AIR VENT

Refer to Figure 47

a)

Ensure supply voltage is isolated.

b) Drain down the appliance; refer to section 9.24.

c) Disconnect the vent tube from the auto air vent and check that it

is free from blockage.

d) Unscrew the auto air vent, and fit replacement.

e) Re-assemble in reverse order; ensure that all joints and seals are

correctly re-fitted.

f) Open the isolating cocks and vent air from the system using the

manual air vent. Re-pressurise the system as necessary and check for

water leaks.

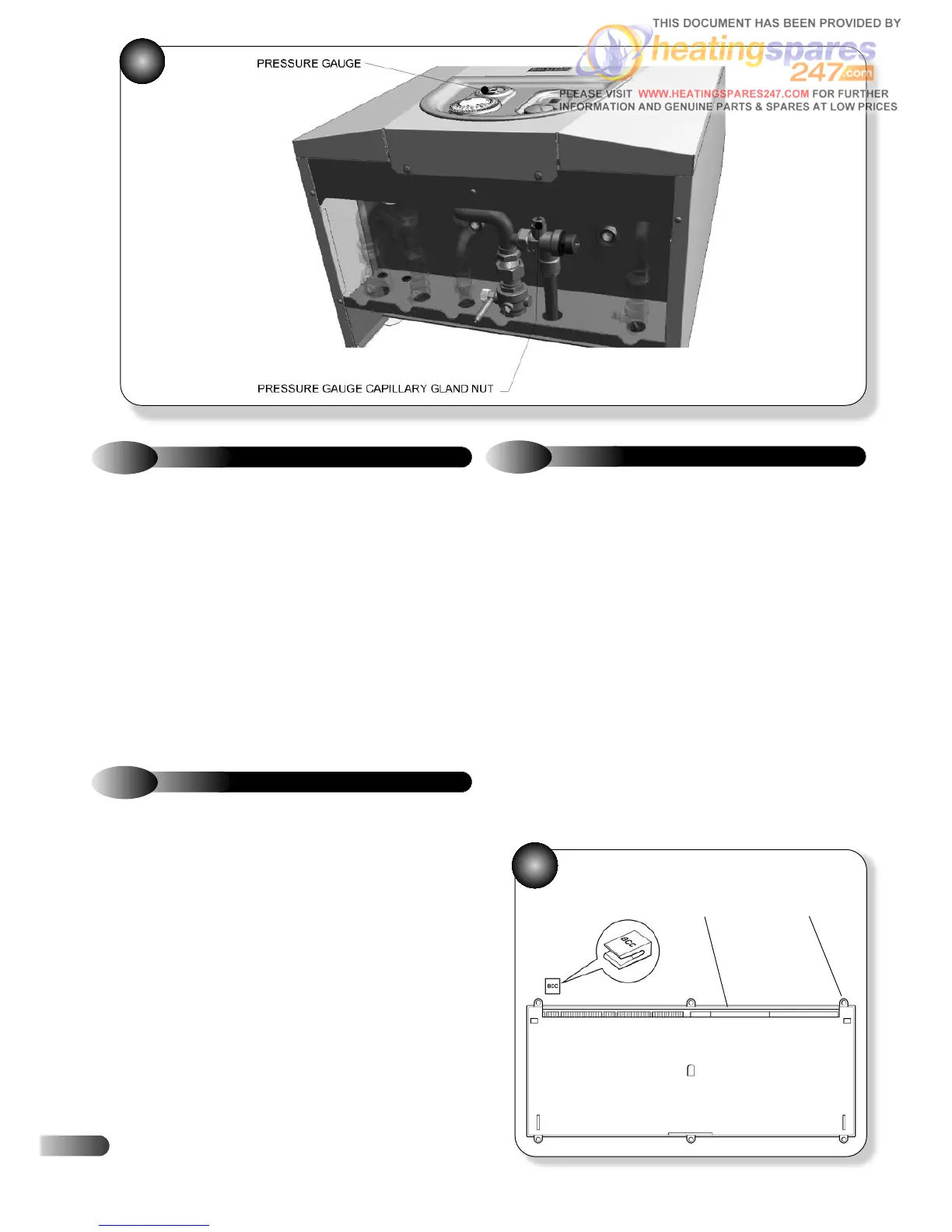

9.20

CONTROL PCB

Refer to Figures 21, 29 & 52

a)

Ensure supply voltage is isolated.

b) Remove the casing front panel, unscrew and lower the control

fascia panel.

c) Unplug the electrical leads from the PCB. Refer to section 7.

d) Unplug the BCC if fitted.

e) Unscrew and remove the PCB plastic cover.

f) Unclip the user interface ribbon cable.

g) Unclip the PCB and withdraw.

h) Fit the new PCB and plug in the BCC if previously used.

i) Re-assemble in reverse order, ensuring user interface ribbon

cable is attached securely.

If the boiler requires resetting turn the control knob anti-clockwise to

'STANDBY' position and then back to 'ON' within two seconds.

Refer to section 5.4.

52

PCB HOUSING

BCC

Electrical

Connectors

Securing

Screws

•

•

Loading...

Loading...