9.5

BURNER

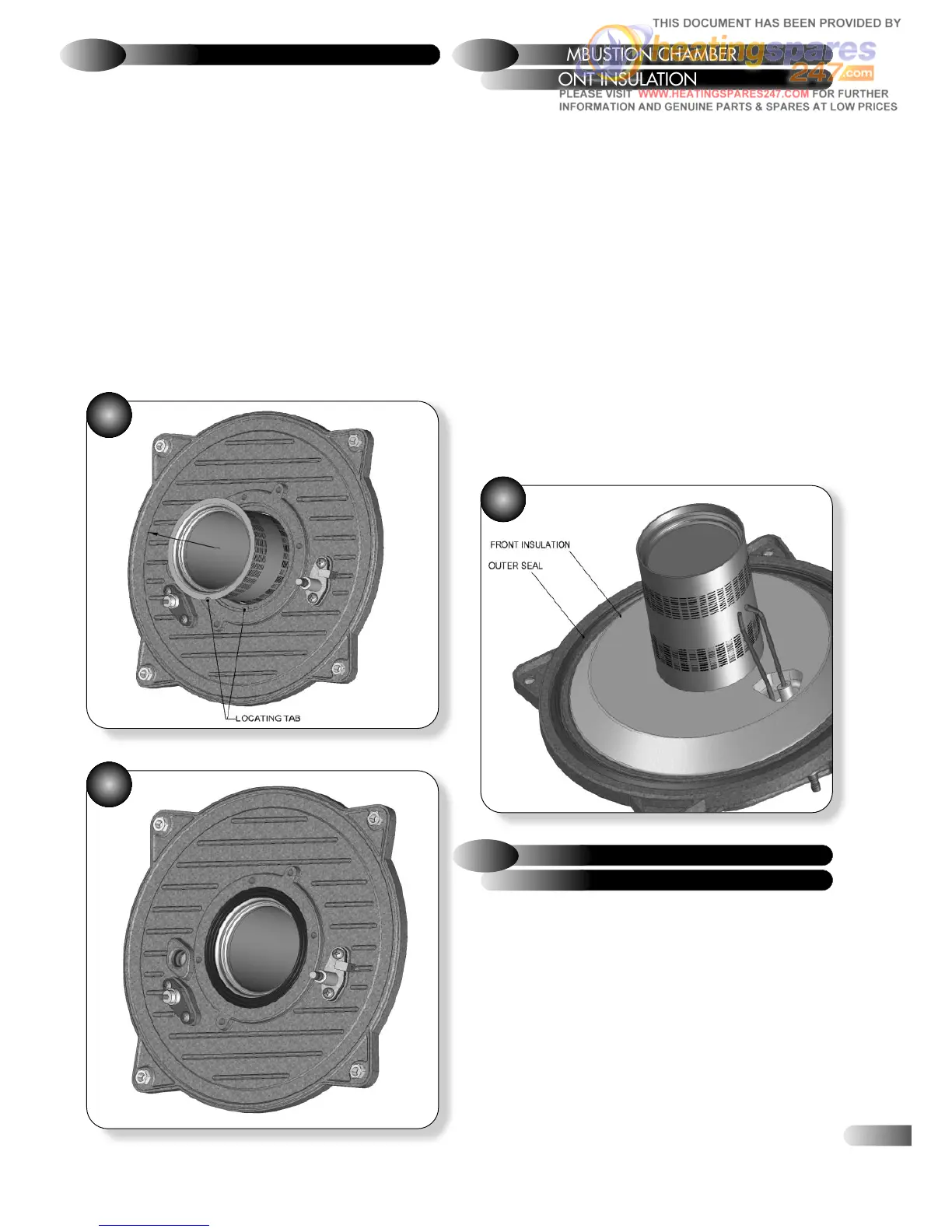

Refer to Figures 34, 40 & 41

a)

Ensure supply voltage is isolated, and that the gas supply is

isolated.

b) Remove the gas control valve, fan & burner assembly; refer to

section 6.2.

c) Unscrew the three Torx screws, (T-25), holding the manifold to the

combustion chamber door, and remove the manifold; refer to Figure

34.

d) Remove the gasket, and withdraw the burner; refer to Figure 39.

e) Fit replacement burner, taking care not to damage the insulation,

and ensure burner is correctly located by lining up the locating tab.

f) Fit new gasket; refer to Figure 40.

g) Re-assemble in reverse order; ensure that all joints and seals are

correctly re-fitted.

40

41

The design of the appliance is such that the combustion chamber

insulation should not require replacement unless mechanically

damaged. It is recommended that to prevent dust, the insulation is

dampened prior to removal, and that a protective mask is worn

when changing or handling the insulation material.

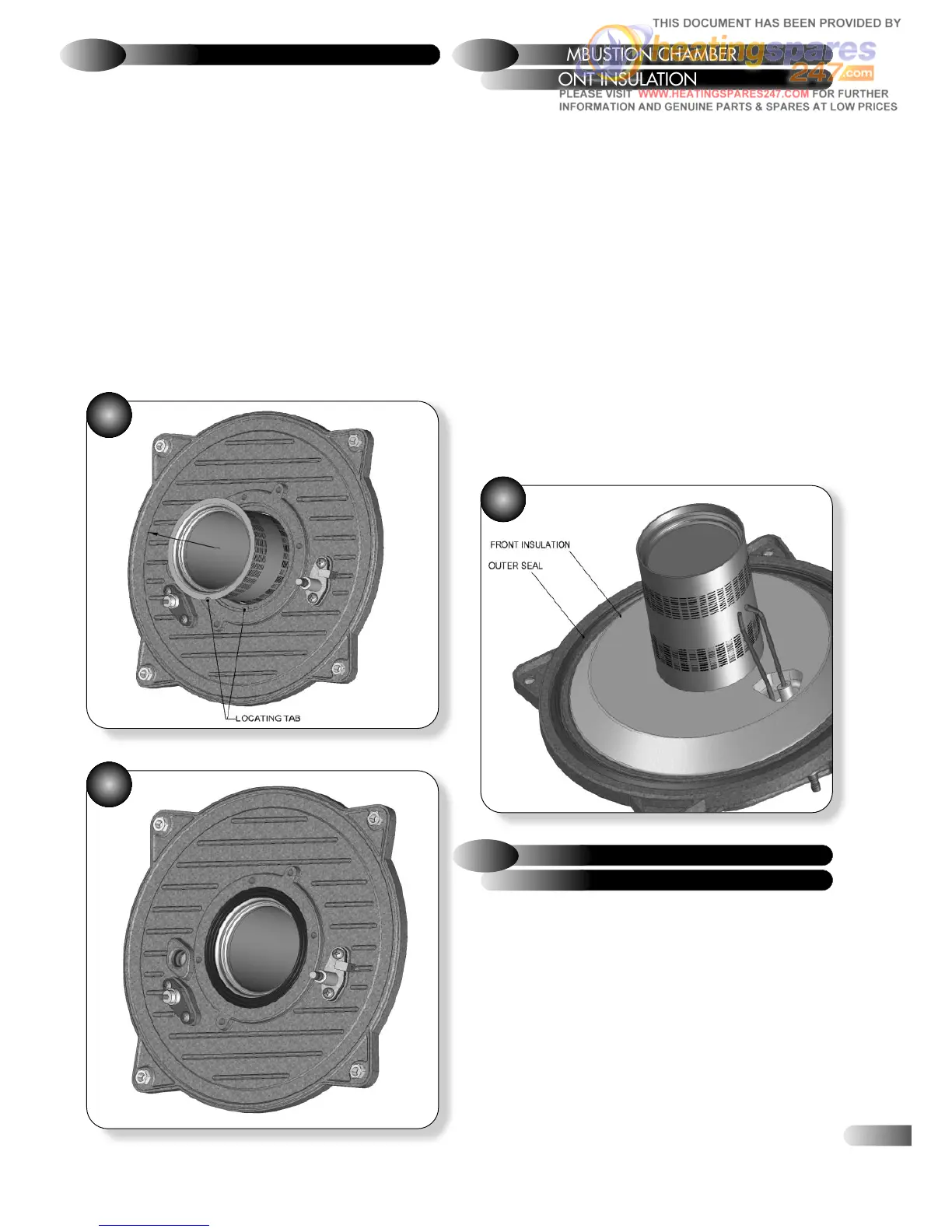

Refer to Figure 42

a)

Ensure supply voltage is isolated, and that the gas supply is

isolated.

b) Remove the gas control valve, fan & burner assembly; refer to

section 6.2.

c) Remove the electrodes; refer to section 9.1.

d) Remove the burner: refer to section 9.5.

e) Replace the combustion chamber front insulation.

f) Re-assemble the burner and electrodes, using new gaskets.

g) Check the position of the electrodes: refer to section 6.4.

h) Re-assemble in reverse order; ensure that all joints and seals are

correctly re-fitted.

FRONT INSULATION

9.6

COMBUSTION CHAMBER

42

Refer to Figure 43

a)

Ensure supply voltage is isolated, and that the gas supply is

isolated.

b) Remove the gas control valve, fan & burner assembly; refer to

section 6.2.

c) Use an Allen key to undo the central screw holding the rear

insulation in place.

d) Remove old insulation and fit replacement, ensuring locating

washer is in front.

e) Re-assemble in reverse order; ensure that all joints and seals are

correctly re-fitted.

REAR INSULATION

9.7

COMBUSTION CHAMBER

33

Loading...

Loading...