Technical Manual VERSION 2.0 -10-18-2018

59

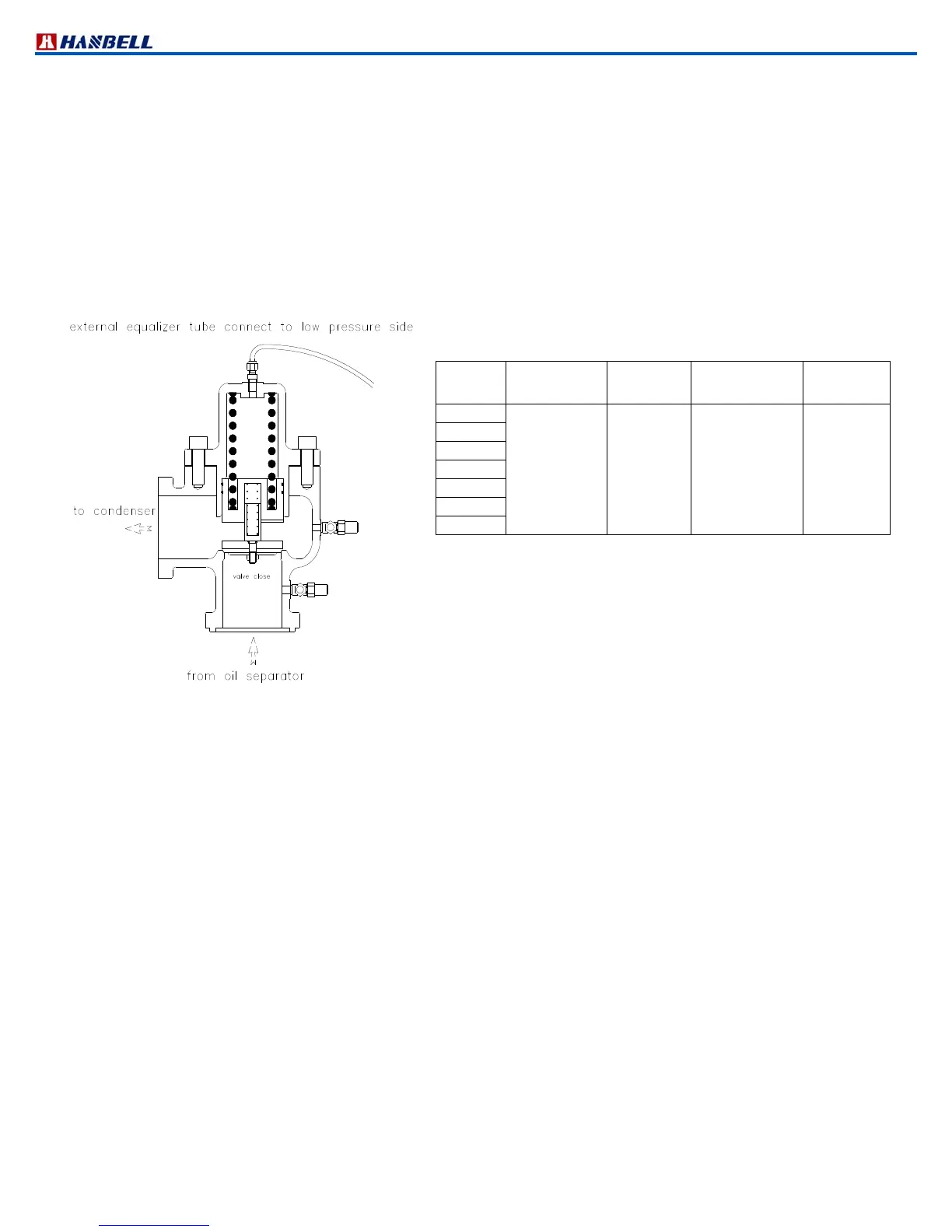

t. Minimum pressure valve(MPV)

Minimum pressure valve is useful in cold start condition. During the cold start period, because the system’s condensing

temperature is still low, the discharge pressure will stay at a quite low level which means the pressure differential

between discharge and suction side will not be enough for compressor to act normally. Under such working condition,

compressor might have difficulties to load itself. Oil supply to bearings and internal cooling might be not enough which

will cause severe damage to those moving parts in the end. With minimum pressure valve, the pressure differential can

be built shortly after the start up, so the capacity control and oil supply to those moving parts won’t be a problem.

Therefore, the compressor protection can be achieved. In addition to protection function, it can also act as check valve

to reduce the reverse running time after compressor’s stopping.

Flange on minimum pressure valves are provided for the ease of installation. It can be installed on either compressor’s

discharge port or external oil separator’s discharge port (F type compressor only). The installation and specification are

shown as below:

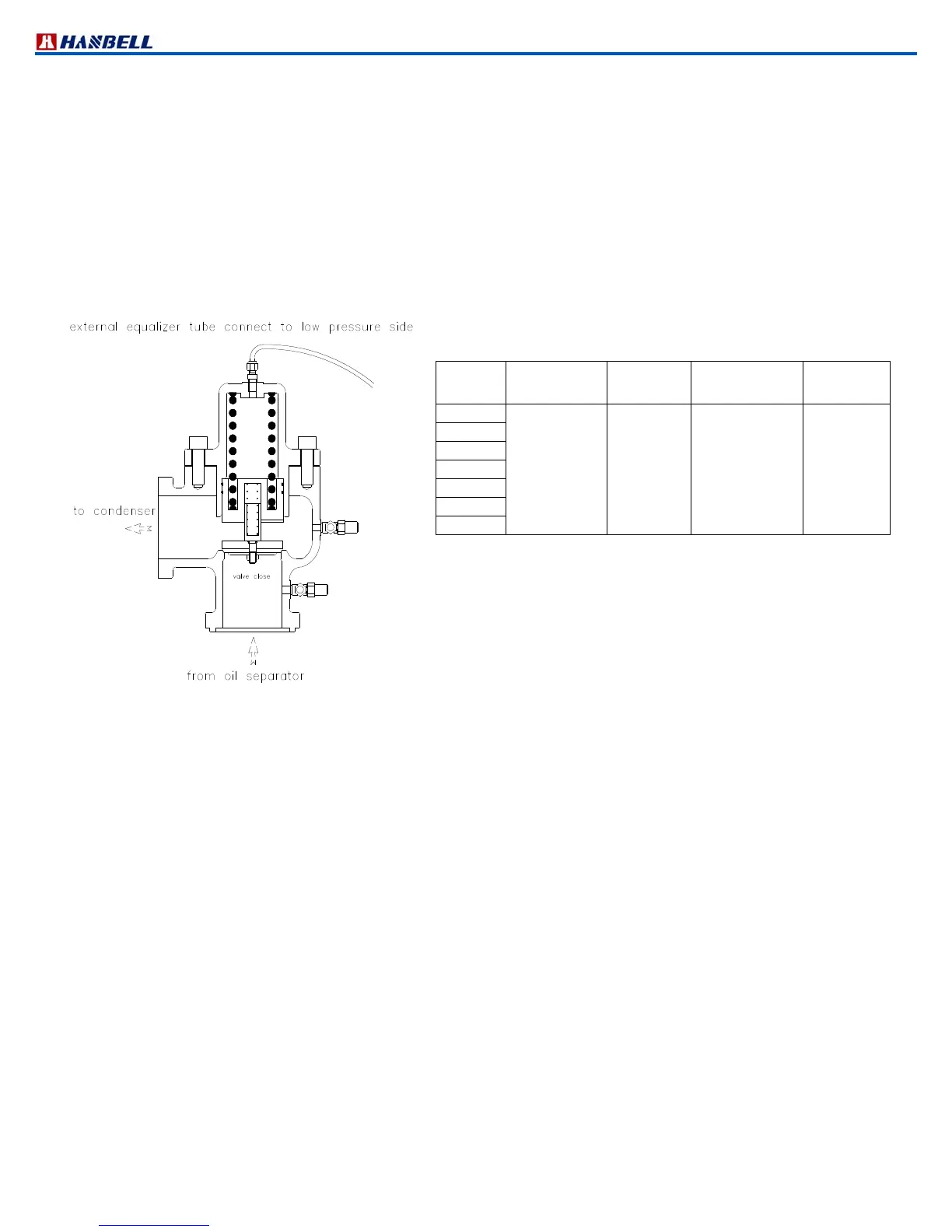

Model

Opening

pressure

Max.

pressure

Working

temperature

Pressure

drop

1 1/2"

3.6±0.3Bar

28Bar

<120℃

<0.1Bar

2"

2 1/2 "

3"

4"

5"

6"

Figure 53 Installation of MPV

Please consult Hanbell representatives for the detailed

outline and application

Loading...

Loading...