1.3.3Driving axle assemble removal and installation

! WARNING

Be careful when removal and installation driving axle as it is heavy.

1) Raise front end of forklift truck and support frame with wooden blocks.

2) Remove mast assembles.

3) Slightly raise axle with a hoist and place wooden blacks under differential gear carrier and

transmission case.

4) After placing a pan under axle case, loose oil plug, drain oil from axle case.

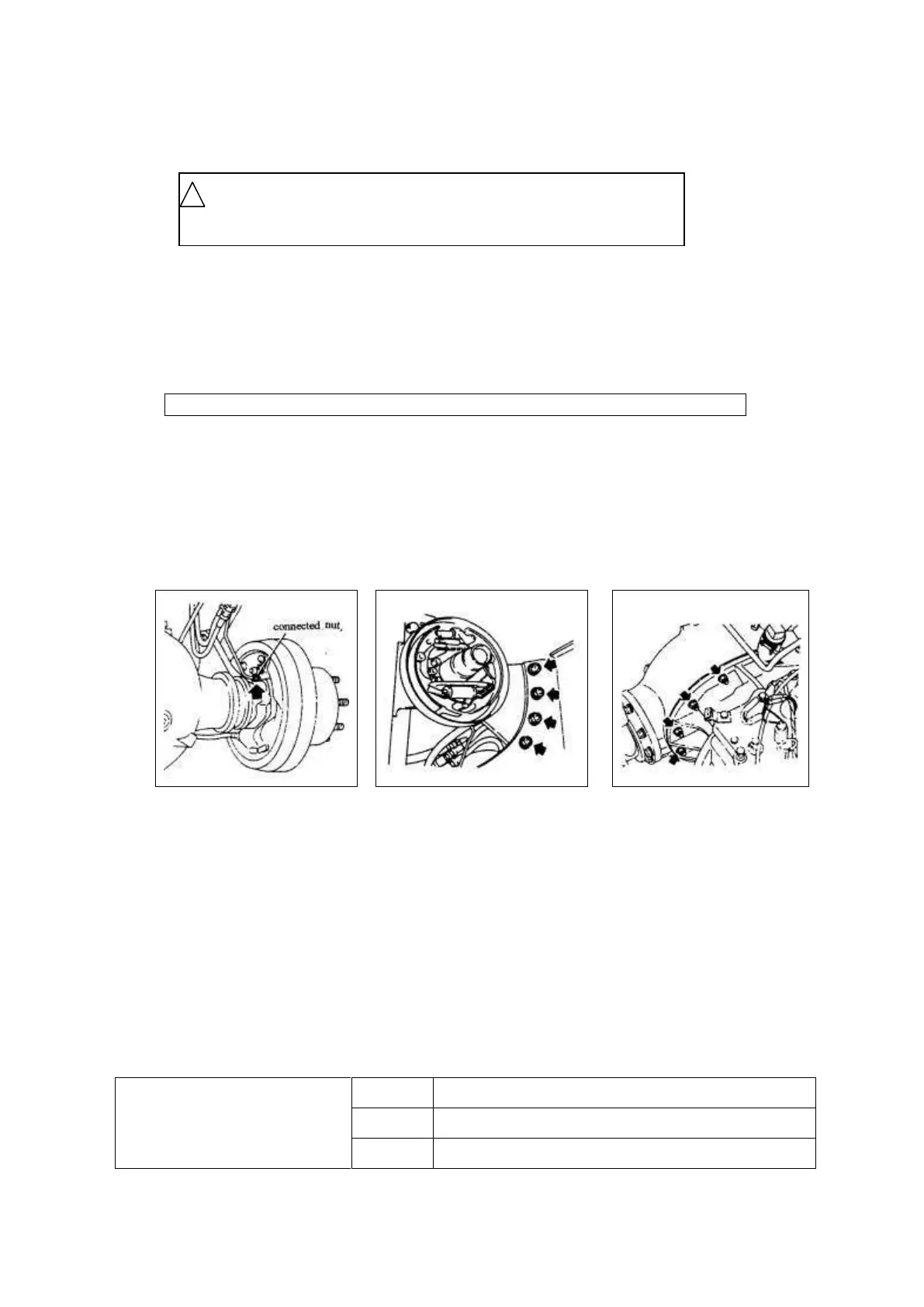

5) Disconnect brake nuts from left and right cylinders.(see fig.5-1)。

CAUTION:Plug brake tube openings to prevent oil from flowing out.

6) Disconnect brake cable at hand brake lever.

7) Remove front wheels.

8) Remove axle shaft.

9) Support driving axle with wire ropes and lifting device.

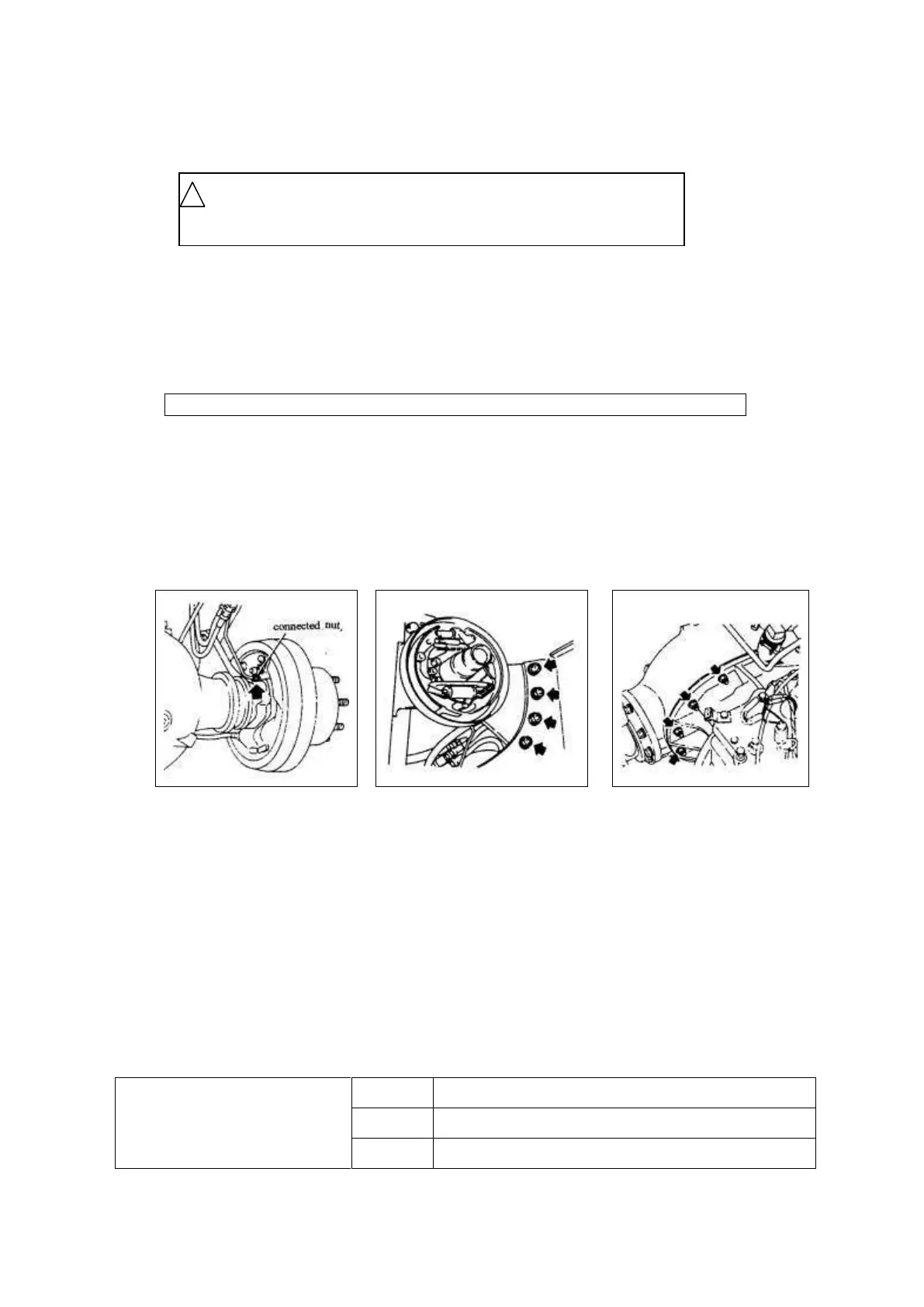

10) Remove bolts securing axle mounting bracket to frame.(see fig.5-2).

11) Remove nuts securing axle case to differential gear carrier.(see fig.5-3).

12) Remove driving axle assemble.

Fig.1-1 Fig.1-2 Fig.1-3

13)Remove brake drum,remove wheel hub.

14)Remove axle mounting bracket and brake component from axle tube.

15)Remove oil seal from axle tube.

16)To install driving axle assemble in the reverse order of removal. Observe the following:

① When installing axle mounting bracket and brake component, apply a coat of calcium grease to axle

tube.

② Apply 1/3~2/3 of volume of calcium grease to wheel hub,then install them on axle tube.

③ Install oil seal with its part number facing to the inside of forklift truck.

④ attach seal tape (PVC, white)to drain plug then installed after cleaned it.

⑤ Replenish axle case with gear oil. Tighten vent plug after clearing.

Loading...

Loading...