35

Procedure

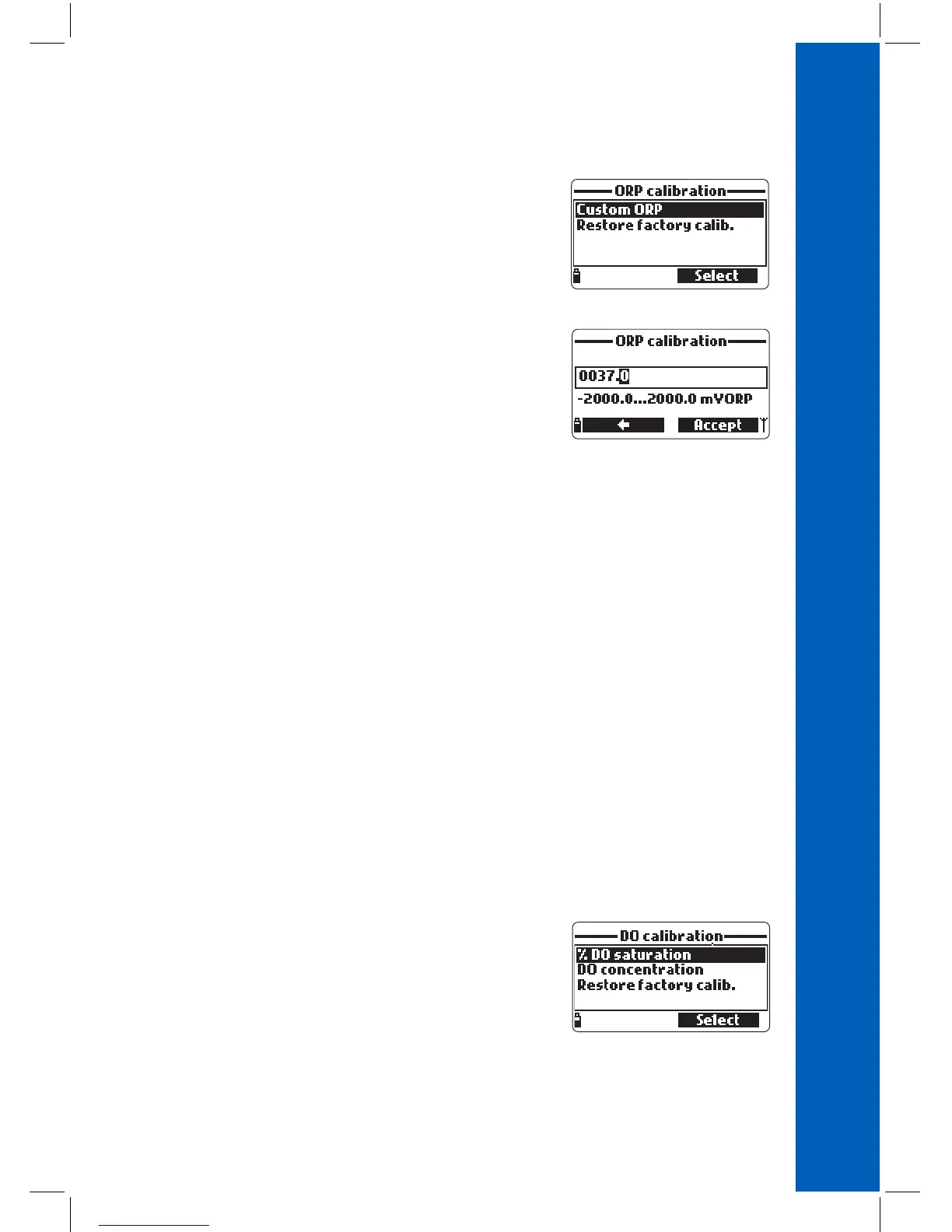

• From the “Calibration” menu select “Single param.

calibration” and then “ORP calibration”. The display shows

two options: “Custom ORP” and “Restore factory calib.”.

• For a user calibration select “Custom ORP”.

• Fill a beaker with an ORP test solution (see APPENDIX C

“Accessories”).

• Using the keypad, insert the numerical ORP value and then

press Accept to confirm.

• The stability counter will count down and the message

“Ready” and Confirm will be displayed.

• Press Confirm to accept the calibration point.

• After confirmation, the following messages are displayed:

“Storing” and “Calibration completed”.

• Press OK to return to the Calibration menu.

• Press Measure to return to the measurement screen.

• To restore the factory calibration data, select the corresponding option in the “ORP calibration”

menu and then press Select.

DISSOLVED OXYGEN CALIBRATION (HI98194, HI98196 only)

The accuracy of dissolved oxygen measurements is directly related to membrane cleanliness and

calibration technique. Oily coating and biological contaminants are the primary cause of calibration

drift in dissolved oxygen sensors.

Unfortunately, brushes or other cleaning objects may damage the membrane.

Replacing the membrane cap and electrolyte is the best way to perform periodic maintenance.

Although it may be easier to calibrate the D.O. sensor prior to deployment, it is advised to calibrate

at the site of deployment. Errors in measurement may result if altitude and barometric pressure differ

between the calibration and measurement site.

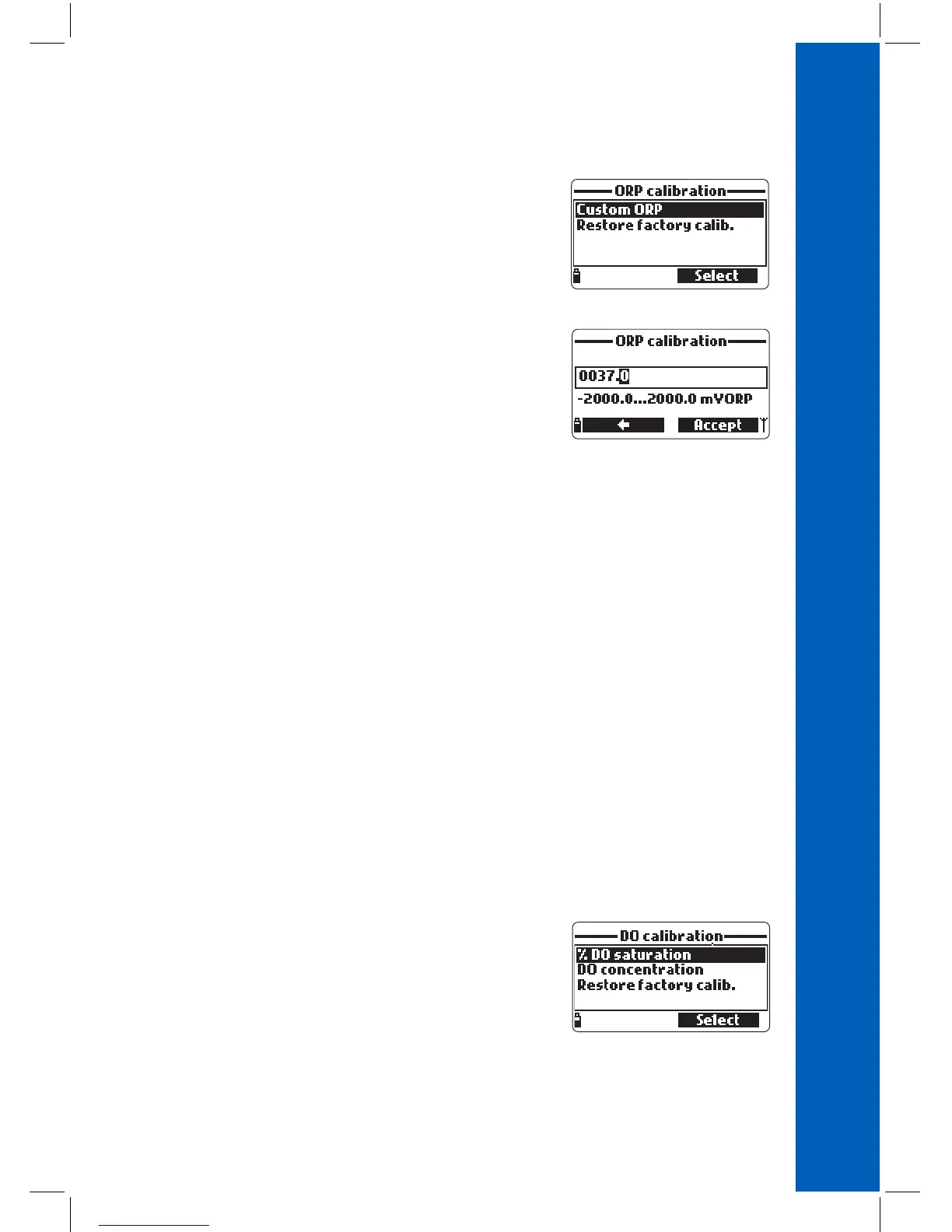

Note: Perform either the % D.O. saturation or D.O. concentration calibration.

If the % D.O. saturation range is calibrated, the D.O.

concentration range will also be calibrated, and vice

versa. Dissolved oxygen concentration values are based on

% D.O. saturation, temperature, salinity and atmospheric pres‑

sure. A standard solution or a reference D.O. meter may be used

to compare readings during calibration.

RELATIVE mV CALIBRATION

D.O. CALIBRATION (HI98194, HI98196 only)

Loading...

Loading...