6 - Maintenance

66

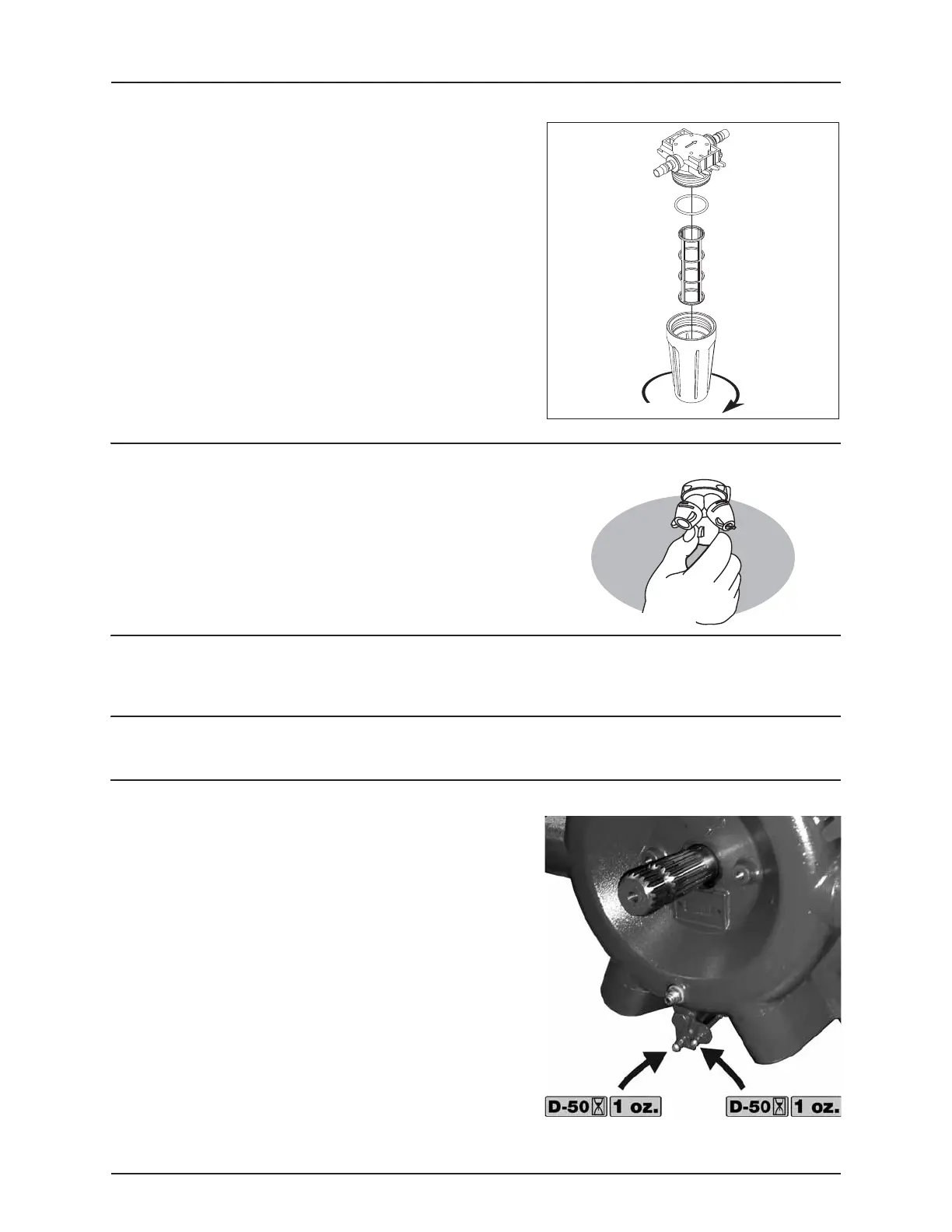

10 hours service -In-Line filter

If the boom is equipped with In-Line Filters, unscrew the filter bowl to

inspect and clean the filter. When reassembling, the O-ring should be

greased.

Alternative filter meshes are available. See “Filters and nozzles” on

page 83.

±

WARNING! Be careful not to splash out liquid when unscrewing

the filter bowl.

±

WARNING! Always wear protective clothing and gloves before

opening the filter!

10 hours service - Nozzle filters

Check and clean.

10 hours service - Spraying circuit

Fill with clean water, operate all functions and check for leaks using higher spray pressure than normal. Check nozzle spray

patterns visually using clean water.

50 hours service - Transmission shaft

Check function and condition of the transmission shaft protection guard. Replace any damaged parts.

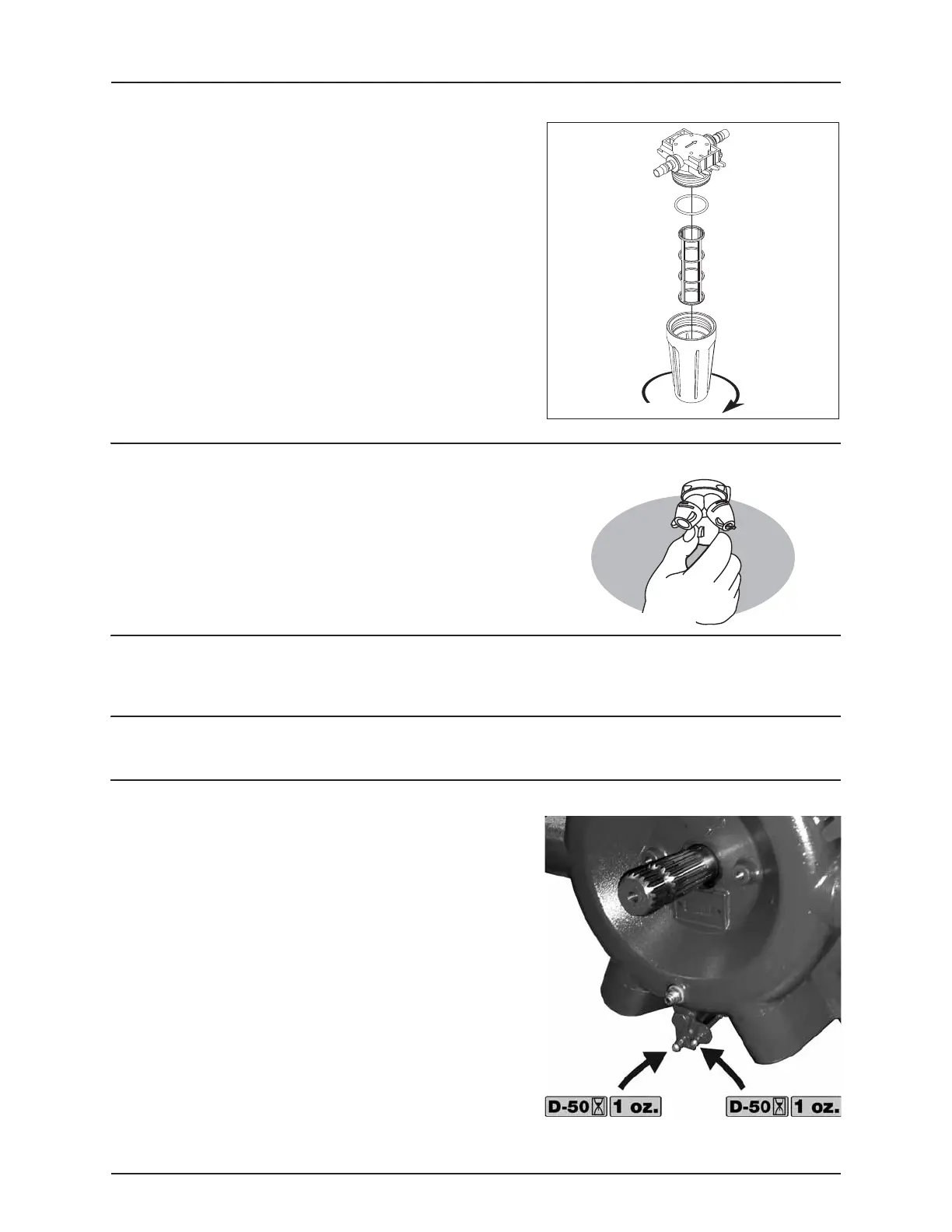

50 hours service - Greasing the 464 pump

When operating the 464 pump, it MUST be greased every 50 hours with

1 oz. (30 grams) grease into each lubrication point.

ATTENTION! In order to avoid excessive wear, it is important to

use a recommended lubricant (i.e. HARDI® part no. 28164600).

See “Recommended lubricants” on page 63.

ATTENTION! The pump MUST be stopped during greasing!

Loading...

Loading...