73

GB 14 08 04

Maintenance

T269-0012

T269-0013

T269-0014

T269-0015

T191-0016

T199-0001

T199-0001

RR

RR

R

ee

ee

e

placement ofplacement of

placement ofplacement of

placement of

tr tr

tr tr

tr

ansmission shaftansmission shaft

ansmission shaftansmission shaft

ansmission shaft

prpr

prpr

pr

otection guarotection guar

otection guarotection guar

otection guar

dsds

dsds

ds

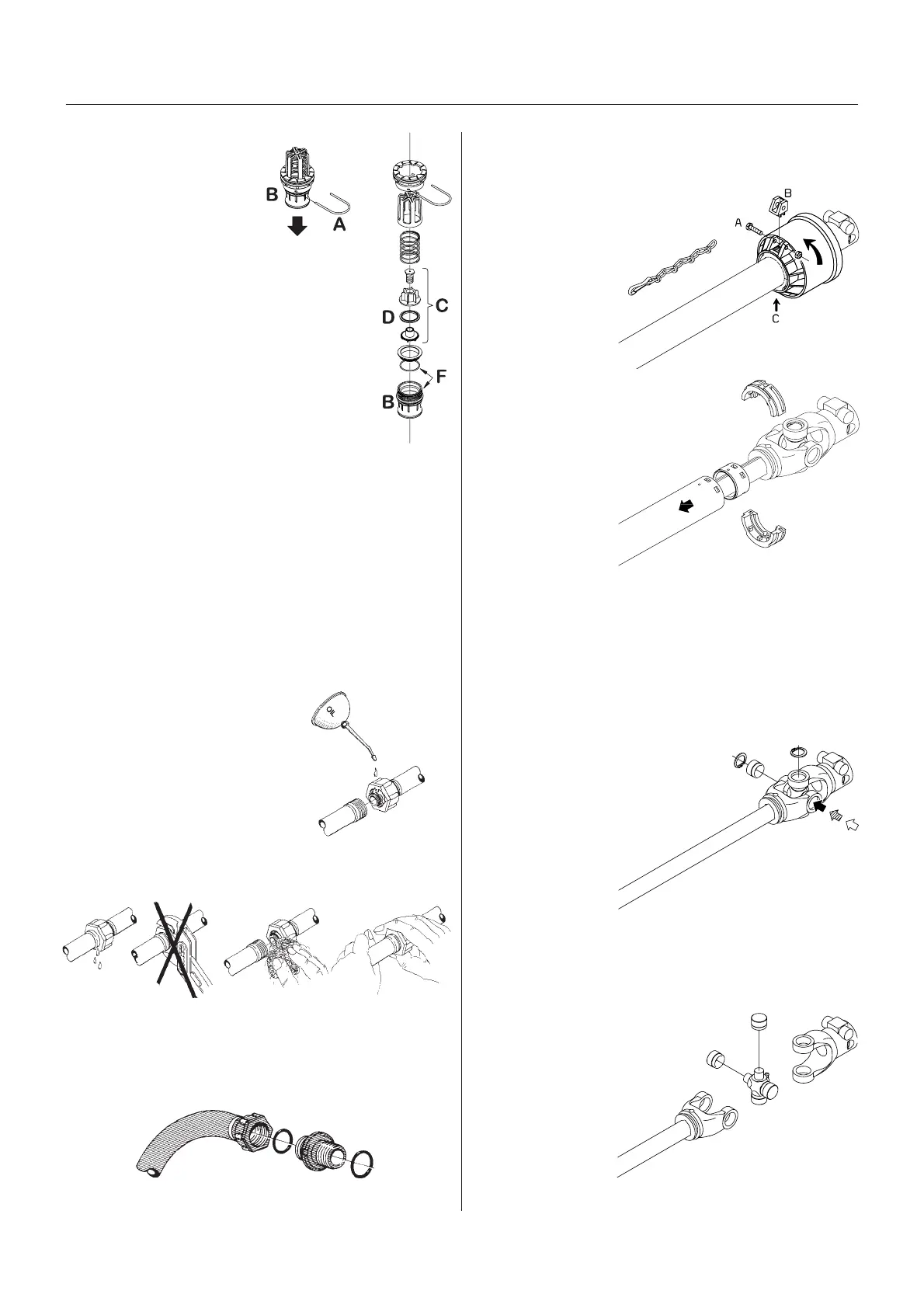

1. Remove bolt A,

lock B and grease

nipple C. Twist uni

CV-joint cover 1/4

turn and pull it

backwards.

2. Remove the

synthetic bearings

and protection

tube.

2a. Remove inner

bush from

protection tube.

3. Assemble again in

reverse order,

using new parts

where necessary.

Remember to fit

chains again.

4. Grease bearings.

NOTE! Only use genuine HARDI spare parts to service

the transmission shaft.

RR

RR

R

ee

ee

e

placement ofplacement of

placement ofplacement of

placement of

tr tr

tr tr

tr

ansmission shaft cransmission shaft cr

ansmission shaft cransmission shaft cr

ansmission shaft cr

ossoss

ossoss

oss

journalsjournals

journalsjournals

journals

..

..

.

1. Remove protec-

tion guard as

described previ-

ously.

2. Remove Seeger

circlip rings

3. Press the cross

journal sidewards

- use hammer and

mandrel if neces-

sary.

4. Remove needle bearing cups and cross journal can

now be removed.

5. Carefully remove needle bearing cups from new cross

journal and install it in reverse

order. Before fitting the needle

bearing cups again, check

that needles is placed

correctly. Avoid dust and

dirt in the new bearings.

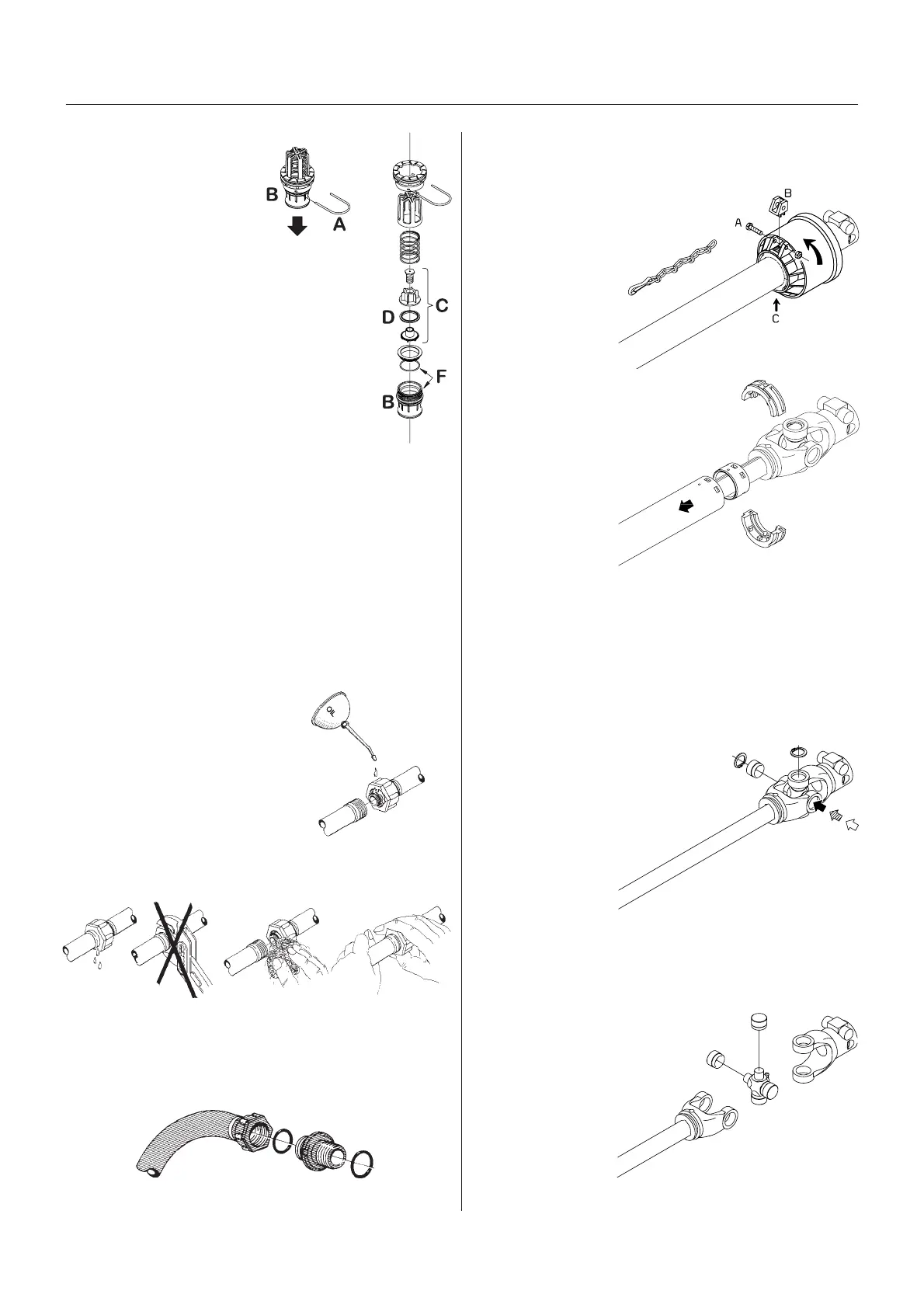

3. Pull out the clip A and pull

down connecting piece B.

The entire valve assembly

can now be pulled out.

4. Check cord and valve flap

assembly C for wear,

replace seal D and as-

semble again.

5. Assemble the valve

assembly again using a

new valve seat E. Lubri-

cate O-rings F before

assembly.

6. Fit clip A again.

NOTE! Check function of

valve with clean water before

filling chemicals into the tank.

Nozzle tubes and fittings

Poor seals are usually caused by:

Missing O-rings or gaskets

Damaged or incorrectly seated O-rings

Dry or deformed O-rings or gaskets

Foreign bodies

In case of leaks:

DO NOT overtighten. Disas-

semble, check condition and

position of O-ring or gasket.

Clean, lubricate and reassem-

ble.

The O-ring must be lubricated

ALL THE WAY ROUND before

fitting on to the nozzle tube. Use

non-mineral lubricant.

For RADIAL connections only hand-tighten them.

For AXIAL connections, a little mechanical leverage may

be used.

T199-0002

Loading...

Loading...