35HARDI

®

New NAVIGATOR OPERATOR’S MANUAL

Maintenance

Hoses and tubes

Check all hoses and tubes for possible damage and

proper attachment. Replace damaged hoses or tubes.

1000 Hours / Yearly Service

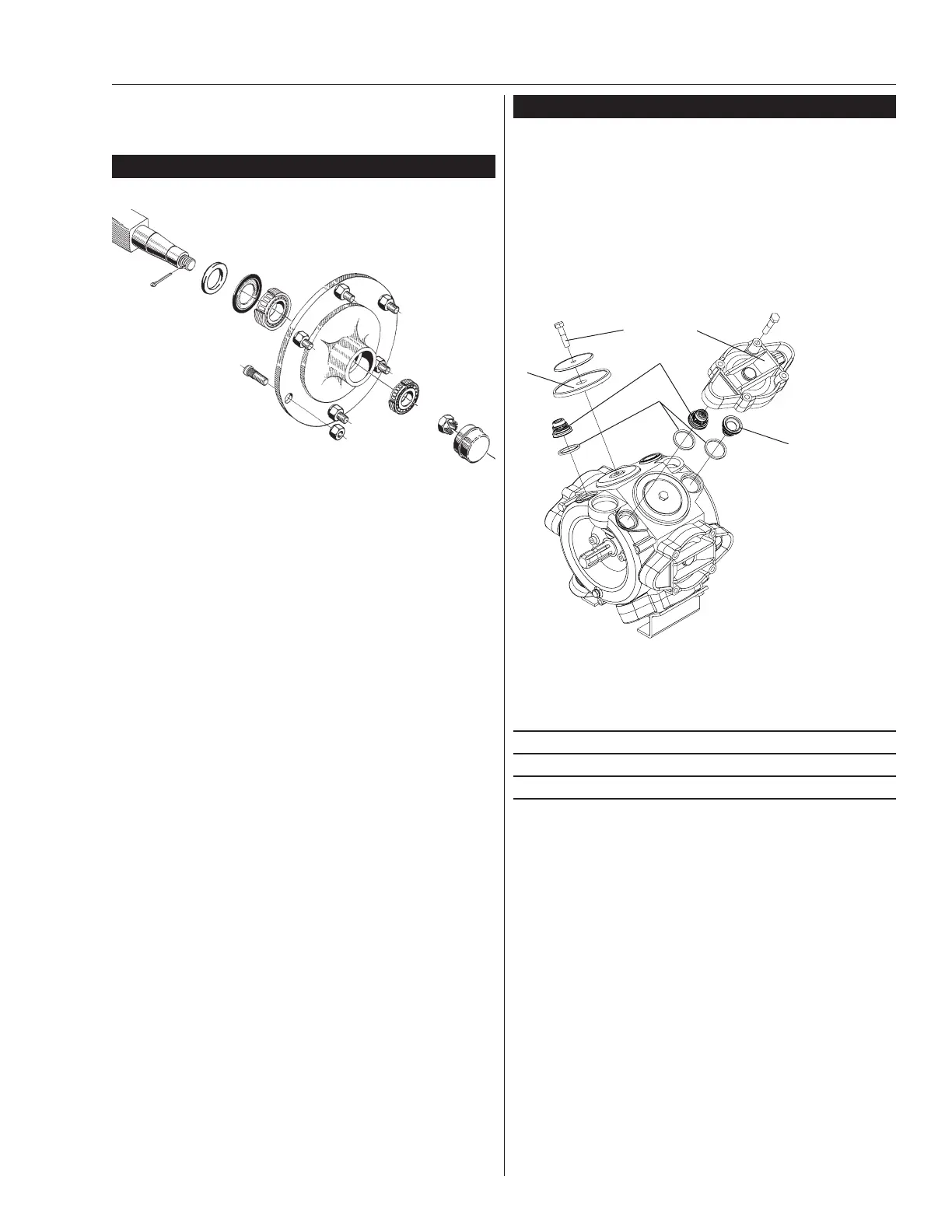

Wheel bearings

Check the condition of the bearings the following way:

1 Place stop wedges in front of and behind the left

hand wheel and jack up the right hand wheel.

2 Support the trailer with axle stands.

3 Remove the wheel.

4 Remove the hub cap (A

Fig 36

), cotter pin

(B

Fig 36

) and castle nut (C

Fig 36

).

5 Pull off wheel hub. Use a wheel puller if necessary.

6 Check roller bearings for discoloration and wear

- replace if worn or damaged.

7 Assemble the hub and bearings using a new sealing

ring (D

Fig 36

).

8 Fill the hub and bearings with fresh grease before

fi tting to the shaft.

9 Fit castle nut. Rotate hub and tighten the castle nut

until a slight rotation resistance is felt.

10 Loosen the castle nut again until the fi rst notch is

aligned with the cotter pin hole in the shaft.

NOTE! The shaft has a vertical and a horizontal

cotter pin hole. Use the one fi rst aligned with the

notch when loosening the castle nut.

11 Fit a new cotter pin and bend it.

12 Fill the hub cap with fresh grease and carefully

press it onto the hub.

13 Fit the wheel again and tighten the wheel nuts.

(Refer

50 Hours / Weekly Service

(Page 34) for

torque wrench setting. Tighten all bolts to half

the specifi ed torque fi rst, then to the full specifi ed

torque.

14 Tighten again after 10 hours of work. Check the

torque every day until it is stabilized.

15 If you do not feel totally confi dent changing wheel

bearings, contact your HARDI

®

dealer’s workshop.

Occasional maintenance

Maintenance and replacement intervals for the next

points depend very much on conditions under which

sprayer operates, and are therefore impossible to

specify.

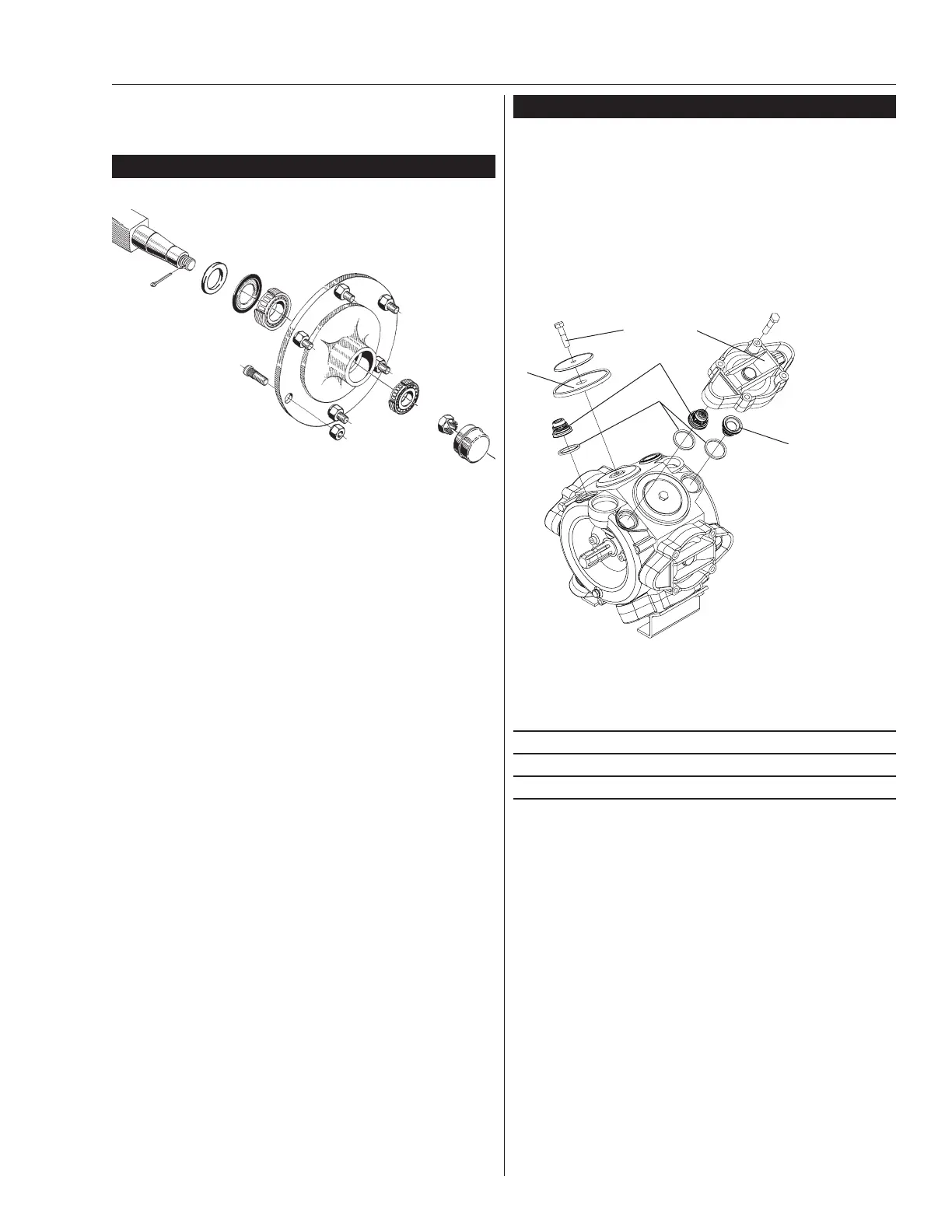

Pump valves and diaphragms replacement

(363/463 pumps)

NOTE! It is recommended that if one or more

diaphragms and/or valves need replacing they all

should be replaced

Diaphragm pump overhaul kit (valves, seals,

di a phragms, etc.)

Pump model HARDI

®

part No.

363 750342

463 750343

Changing valves

1 Remove the valve covers (A

Fig 37

). Before

chang ing the valves (B & B1

Fig 37

) note their

orientation so they are replaced correctly.

2 The two white fl ap valves (B1

Fig 37

) must be

placed in the valve openings as shown. It is

rec om mend ed to use new O-rings (C

Fig 37

) when

chang ing or checking the valves.

Changing diaphragms

1 With the valve covers removed as explained above,

remove the diaphragm bolts (D

Fig 37

).

2 The diaphragms (E

Fig 37

) may now be changed.

3 If fl uids have reached the crankcase, re-grease the

pump thoroughly. Also check the drain hole at the

bottom of the pump is not blocked.

E

A

B

B1

C

D

A = Valve Cover

B = Valves

B1 = White Flap Valves

C = O-rings

D = Di a phragm Bolt

E = Diaphragm

A

B

C

D

Fig 36

Fig 37

Loading...

Loading...