2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 13

MM10001

Dated 1/1/08

Rev L dated 5/21/15

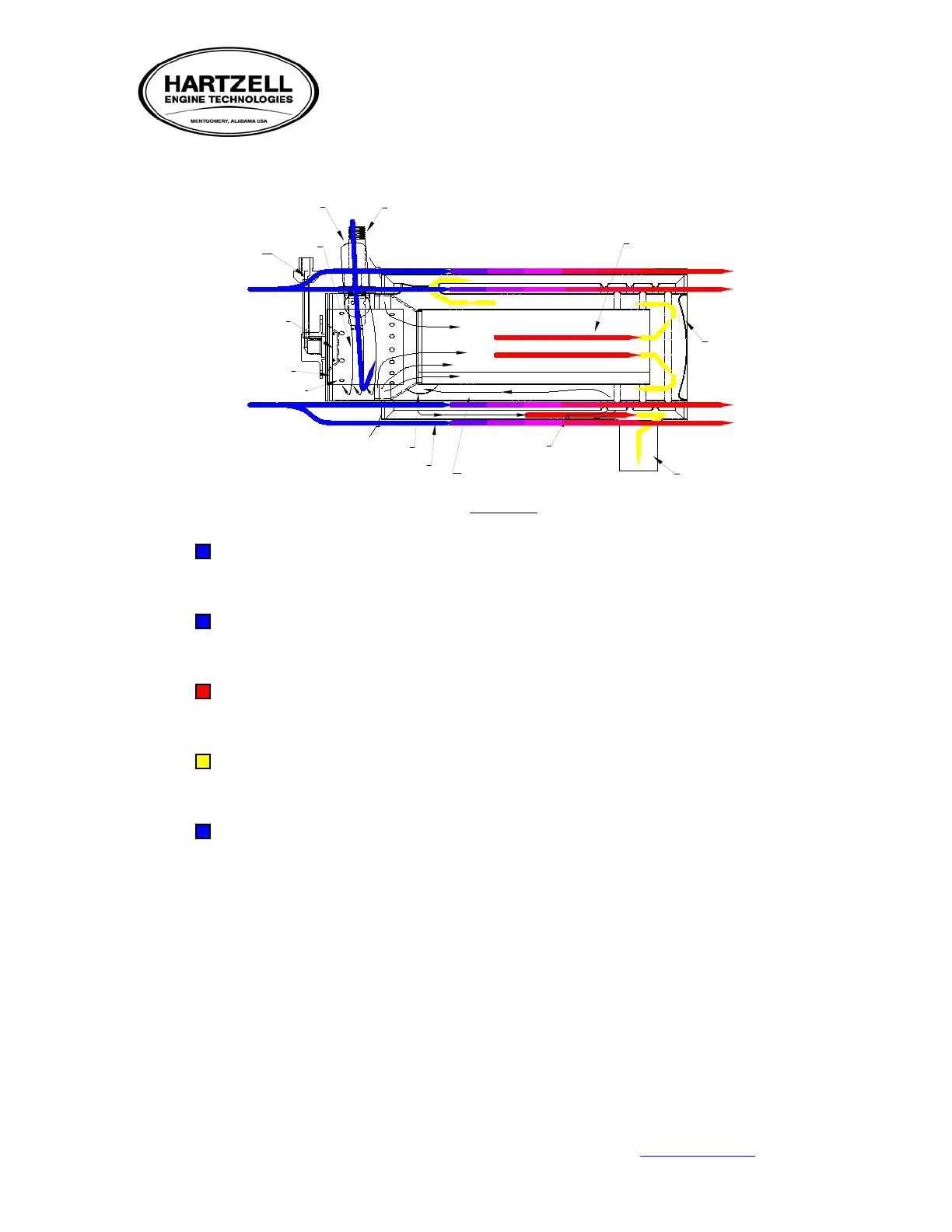

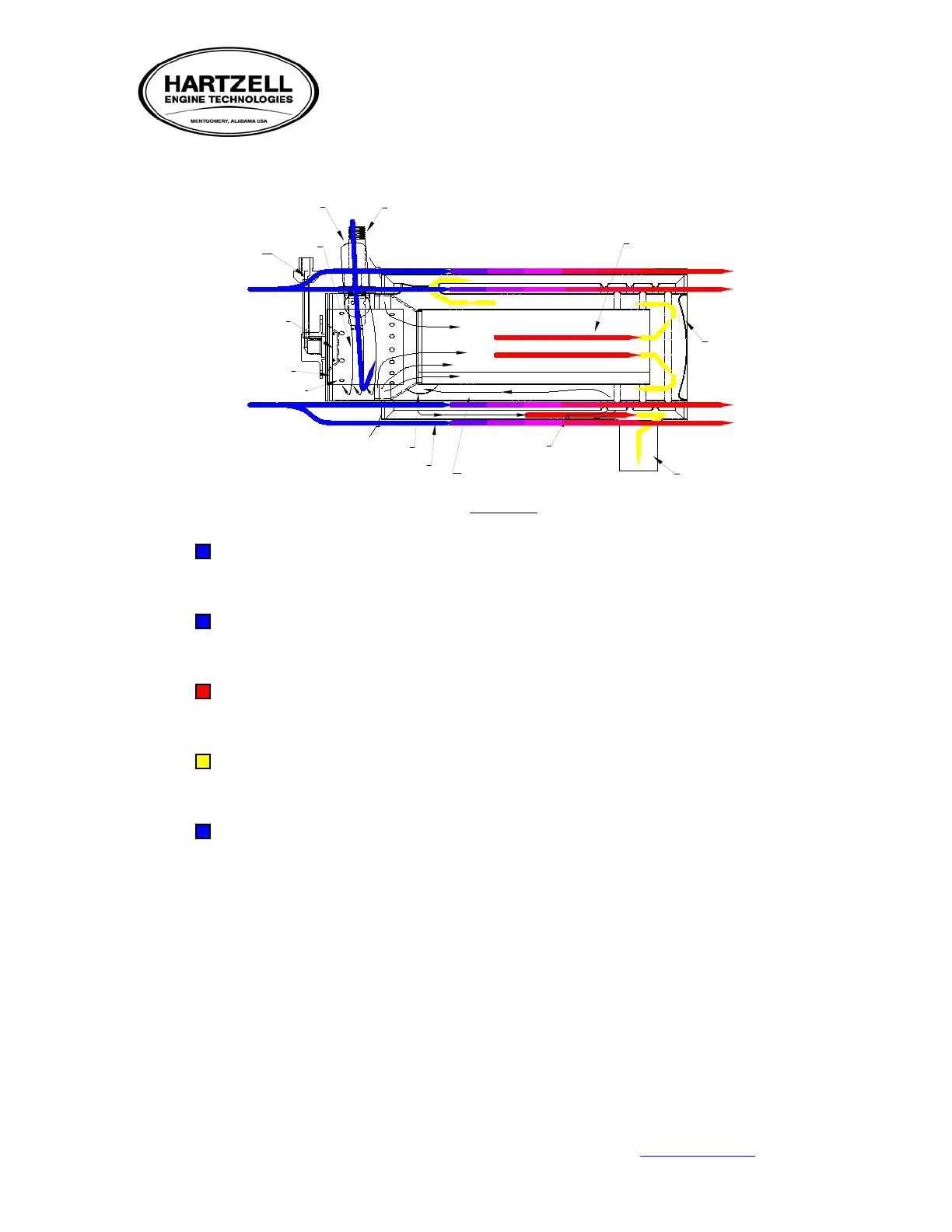

A

B

C

D

D

CONVEX

END DOME

EXHAUST

COMBUSTION

CHAMBER/FLAME TUBE

BAFFLES

HEAT

EXCHANGER

CROSSOVER

MIXER ASSEMBLY

HEAD

ASSEMBLY

FUEL

INJECTOR

REVOLVING

SPARK

FUEL SUPPLY

INCOMING

COMBUSTION

AIR

IGNITOR

JACKET

E

E

HEATED AIR

VENT/FRESH AIR

FIGURE 2

A. Combustion Air Supply. This is provided by way of an external ram air scoop and or a blower

assembly independent of the vent/fresh air supply. Combustion air enters the head assembly, and

then is metered into the mixer chamber.

B. Ignition is supplied via high-voltage oscillating current, this coupled with the igniter design, create

a revolving continuous spark located in the head assembly. This igniter is positioned in the path of

an internal fuel injector designed to atomize the fuel at a pre-determined pressure.

C. This ignited fuel/air mix is then dragged from mixer assembly as additional combustion air

channels through the head assembly into the combustion chamber portion of the liner. The

majority of combustion is created at this point in the combustion chamber or flame tube area.

D. The flame travels full length of the flame tube hitting the end dome, it then doubles back along the

inside wall and on into the outer layer of the heat exchanger. The spent gasses again travel the

length of the tube around a series of baffles then exiting out the exhaust.

E. Air for the ventilation system is picked up via an external ram air scoop and/or a blower assembly

typically mounted on the inlet end of the jacket. Air is forced through the heated external passages

of the combustion chamber. Ventilating air thus comes in contact with the heated cylindrical

surfaces subsequently pushing heated air into the cabin.

Loading...

Loading...