2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 26

MM10001

Dated 1/1/08

Rev L dated 5/21/15

9.3.3 NOZZLE SPRAY TEST

NOTE: At 2000hr/10yr overhaul, nozzle must be replaced.

WARNING: Keep atomized fuel away from a spark, etc., or a fire will result.

Screw the spray nozzle into the nozzle holder and tighten to 75-100 inch-pounds. This

torque is very important as incorrect tightening could cause an improper spray pattern or

could cause nozzle core to become loose. No thread sealant is necessary between nozzle

and nozzle holder.

Connect the fuel feed and nozzle holder assembly tube to a source of fuel; 7±.5 PSI

minimum for AV gas, 100 PSI for jet fuel. No thread sealant is necessary between nozzle

and nozzle holder.

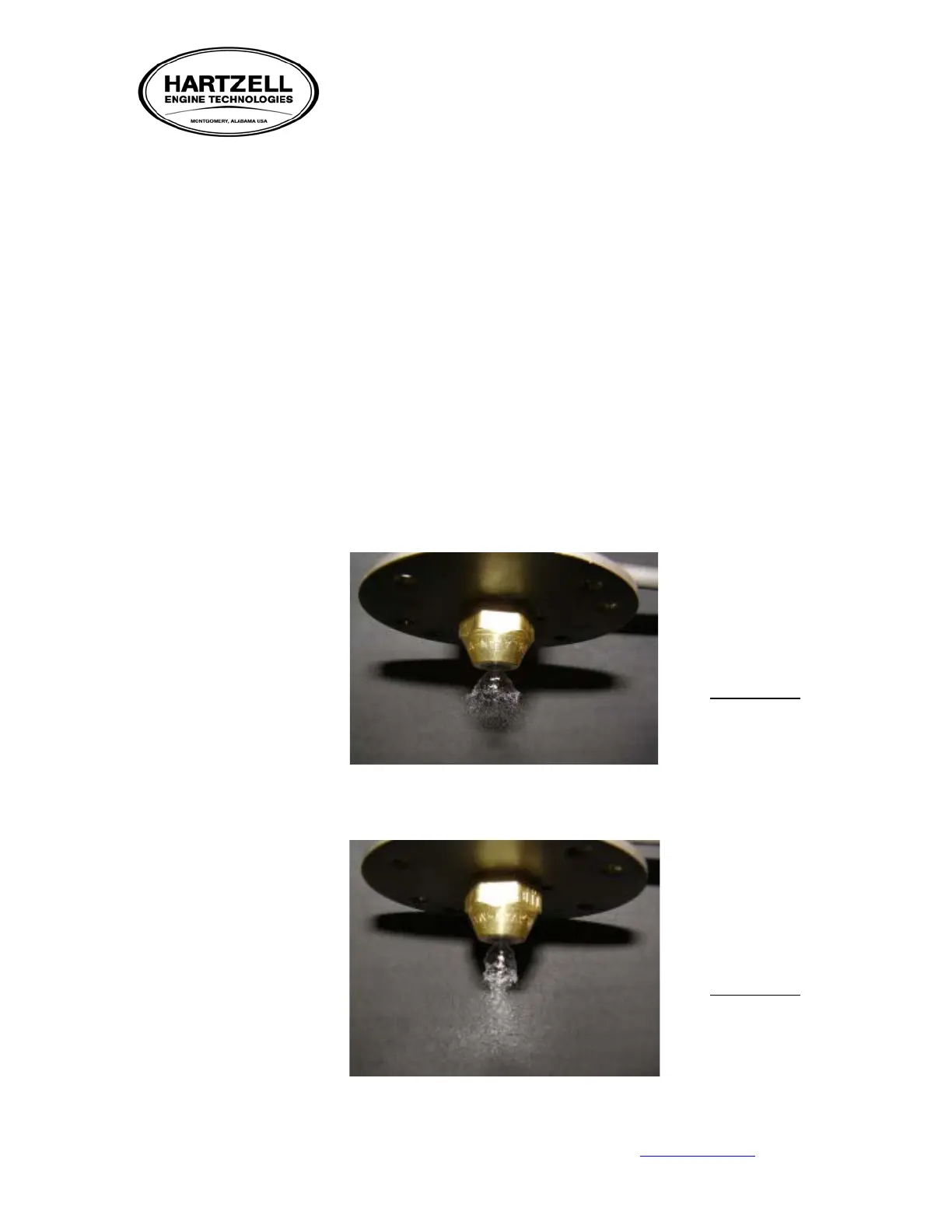

Observe the spray patterns of the nozzle. It should be conical in shape with an even, fine

mist pattern in all directions. NO 'ONION' SHAPE.

With the fuel pressure being shut off several times, there should only be one or two

droplets at the nozzle tip.

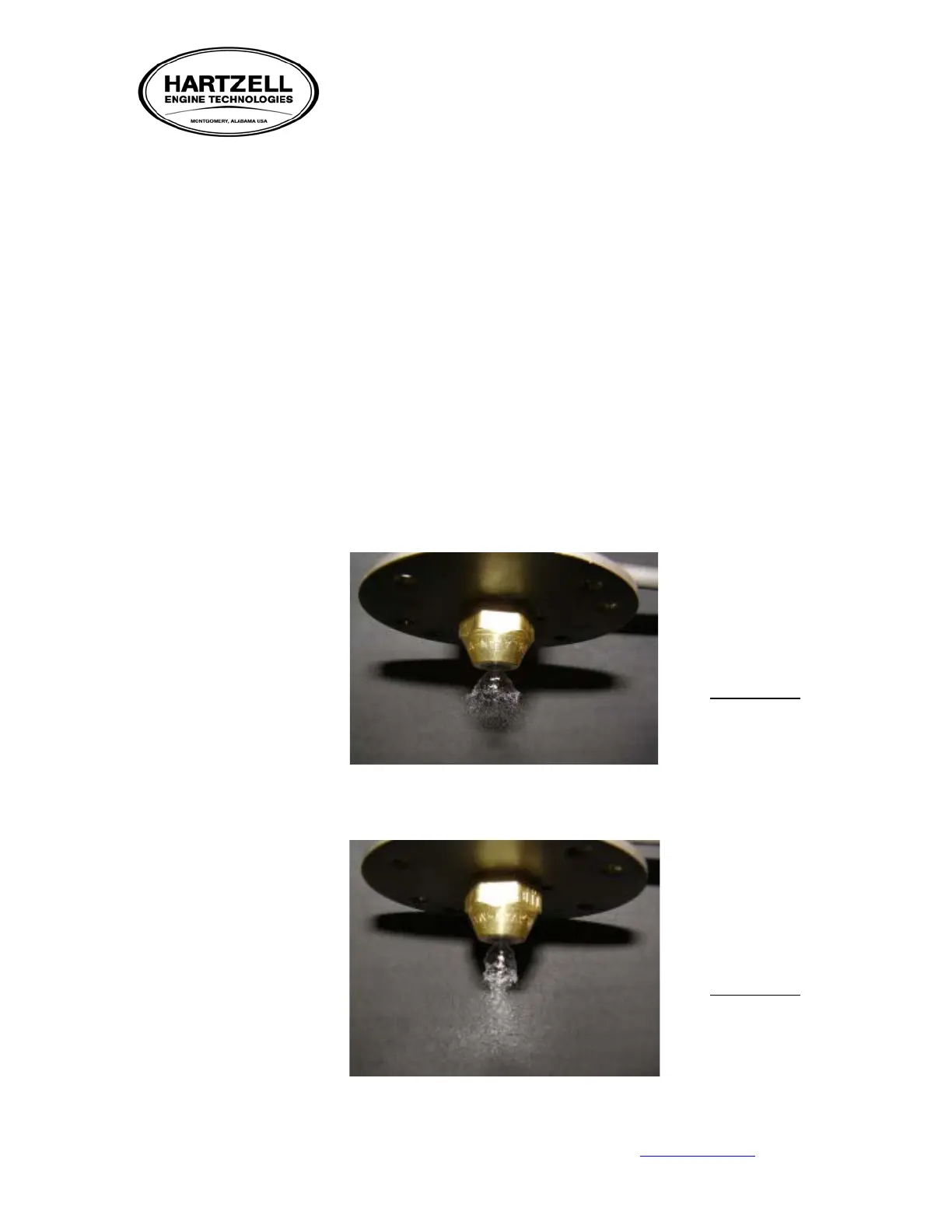

If the spray pattern is distorted, replace the nozzle.

Proper spray pattern is as shown in figure 15 with approximately ¼” of even sheet, or

funneling of the fuel. At this point atomization will occur producing a fine mist.

Improper spray pattern is as shown in figure 16. Typically the sheet or funneling action

would be distorted or “onioning”, i.e. closing in on itself or atomizing prematurely.

FIGURE 15

FIGURE 16

Loading...

Loading...