19

3.2 Service

In order to function satisfactorily the tractor must be

properly maintained.

The necessary daily lubrication and routine checks,

can, of course, be carried out by the driver.

Where adjustments and repairs are necessary

which require the attention of a qualified mechanic

and the use of special tools, it is advisable to relay

on a workshop. In this case we advice you to

consult your local dealer as to how your tractor

should be looked after as he is in a position to give

you the best possible service. Through service

bulletins and special training courses he is kept

constantly informed of the factory’s

recommendations regarding care of the tractor.

3.2.1. Cost-free service

Before leaving the factory the tractor was thoroughly

tested and adjusted to ensure it is in first-class

condition when delivered to you.

However, it is important that the tractor is given

further checks during the first period of operation.

Bolts must be checked for tightness, various

settings inspected and other minor adjustment

made. Your dealer therefore gives one cost free

service inspection (excluding oil and filter costs)

after 100 hours running.

3.3. Engine

(Please check the Perkins engine manual

)

The tractors have 4 − stroke direct injection diesel

engines

The principle of the turbocharged engine is that

exhaust gases from the engine cylinders drive the

turbo unit which forces air into the cylinders. This

means that a higher power output can be obtained

with economical fuel consumption.

3.4. Power transmission

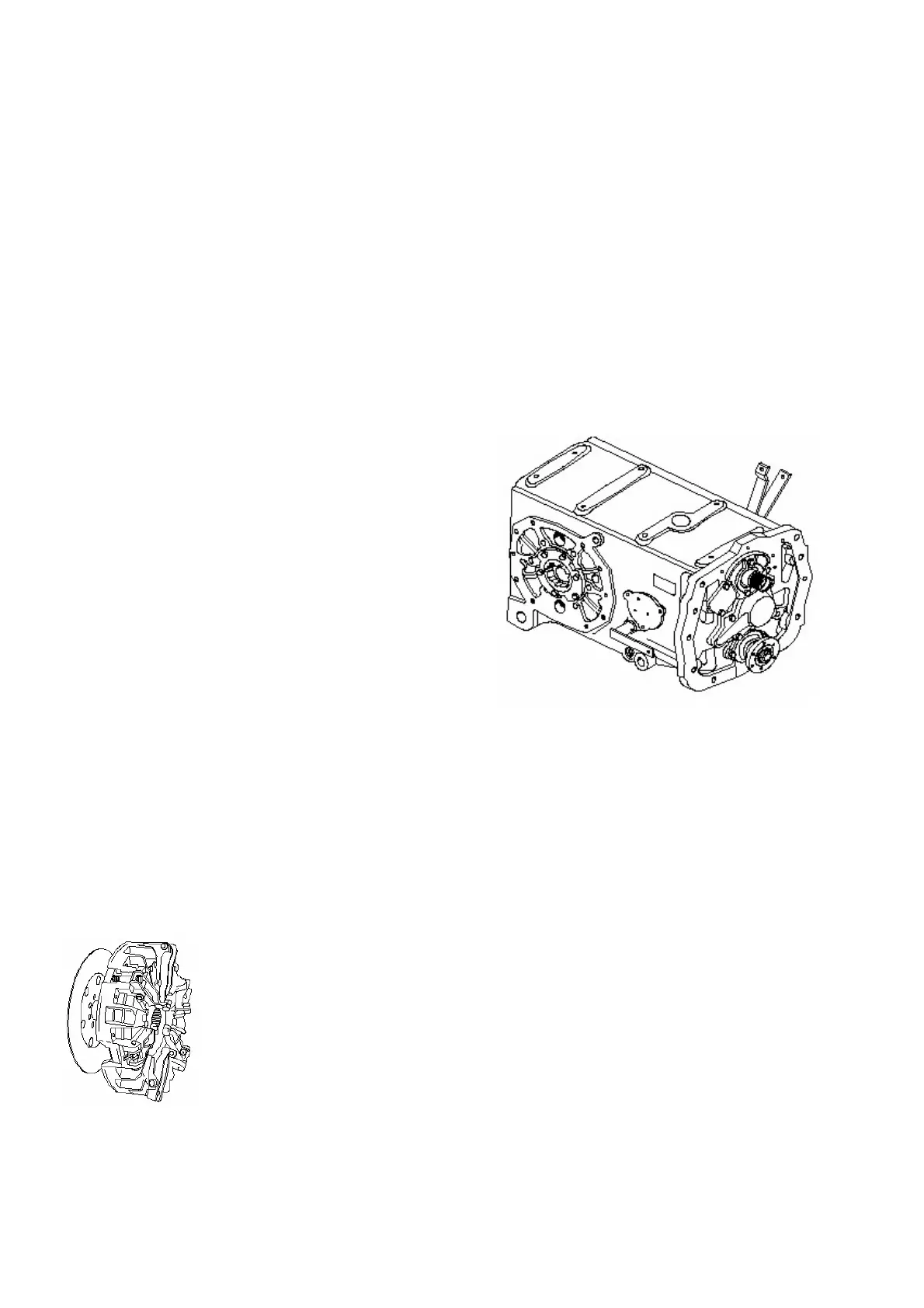

3.4.1 Clutch

The clutch is of the double type

and is attached to the engine

flywheel. There are separate

discs for the propulsion clutch

and power take − off. Both

clutches are operated

mechanically independently of

each other, the propulsion

clutch being controlled by

means of a pedal and the power take − off clutch

with a lever. The clutch plates are both axel and rad

springed

.

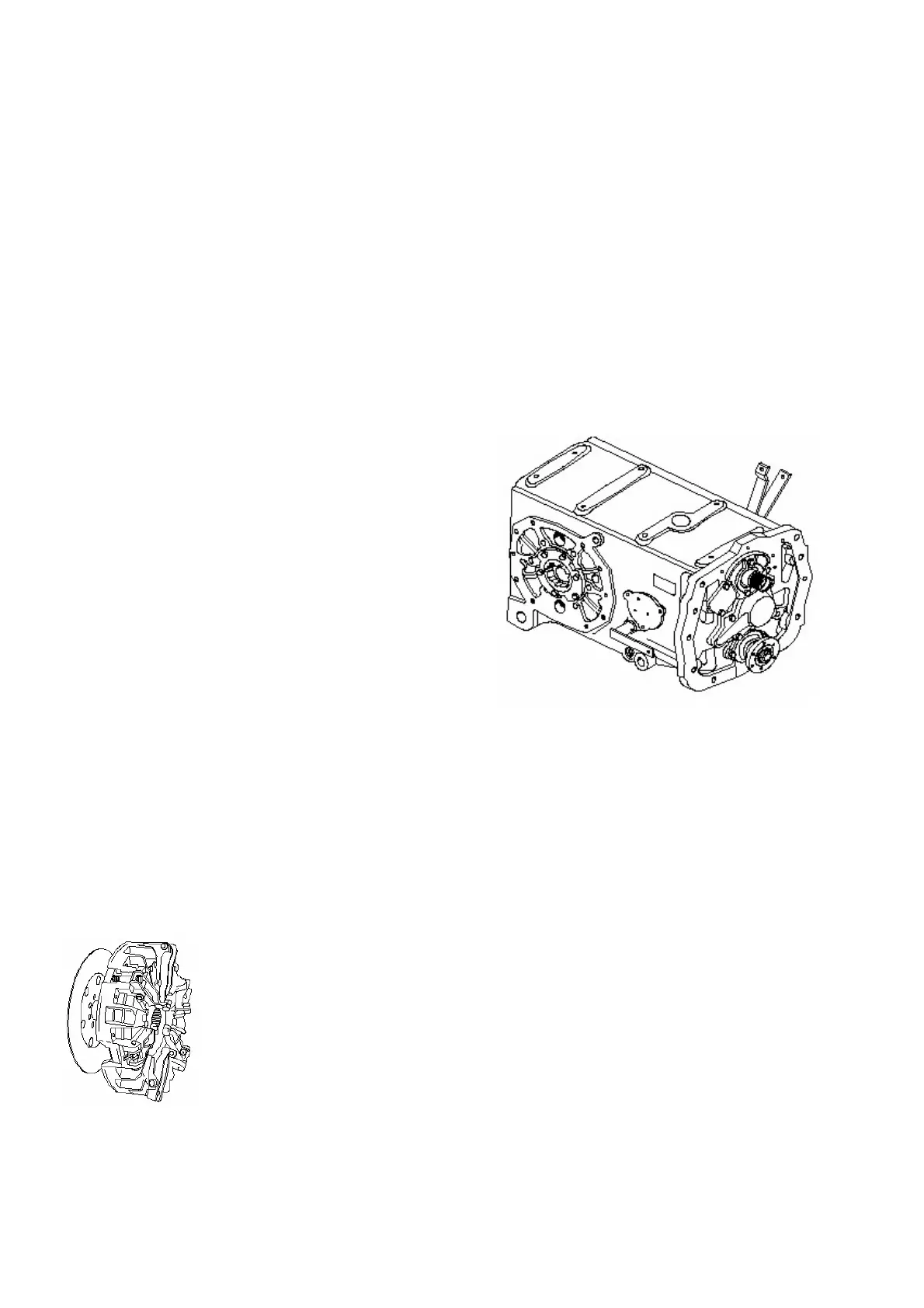

3.4.2. Gearbox

HATTAT tractors have two type of

gearbox(16+8,12+12)The main speed gear are has

four synchronized gears which are controlled with a

speed gear lever. In front of the gearbox there is

fitted a shuttle unit or splitter unit that is changed

according to 16+8 or 12+12.

On models with the shuttle unit the gearbox has

three range gears; LL=creeper range, M=Medium

range and H= High range. M and H ranges are

synchronized. All these three range gears are

controlled with one lever. In the gearbox there are

12 forward speeds and 12 reverse speeds.

On models with the splitter unit the gearbox has two

range gears; L=Low range, H=High range and

R=Reverse speed. Two range speed and R are

controlled with one lever. Two range and R speed

are syncronized.

The gearbox has a common housing with the

differential. Helical gears of the gearbox give a low

noise level and vibration less power transmission.

The gearbox also has pressurized lubrication

provided with an oil filter.

3.4.3. Rear axle

The rear axle is fitted directly to the gearbox.

The differential lock is of the coupling type which is

engaged and disengaged electro − hydraulically. An

indicator lamp on the instrument panel lights up

when the differential lock is engaged.

Final drives are of the planetary gear type. From the

planetary gears power is transmitted to the rear

wheels.

3.4.4. Mechanical Shuttle&Splitter

The shuttle unit is synchronized and has a pressure

lubrication system. The forward reverse shuttle is

controlled with the lever nearest to the driver. For

this reason forward/reverse changing can be made

by stopping the quickly and very easily.

Loading...

Loading...