23©HBS Bolzenschweiss-Systeme GmbH & Co. KG

All rights reserved – Reprinting, in whole or in part, only with the approval of the manufacturer

10 Preparing the Stud Welding Gun

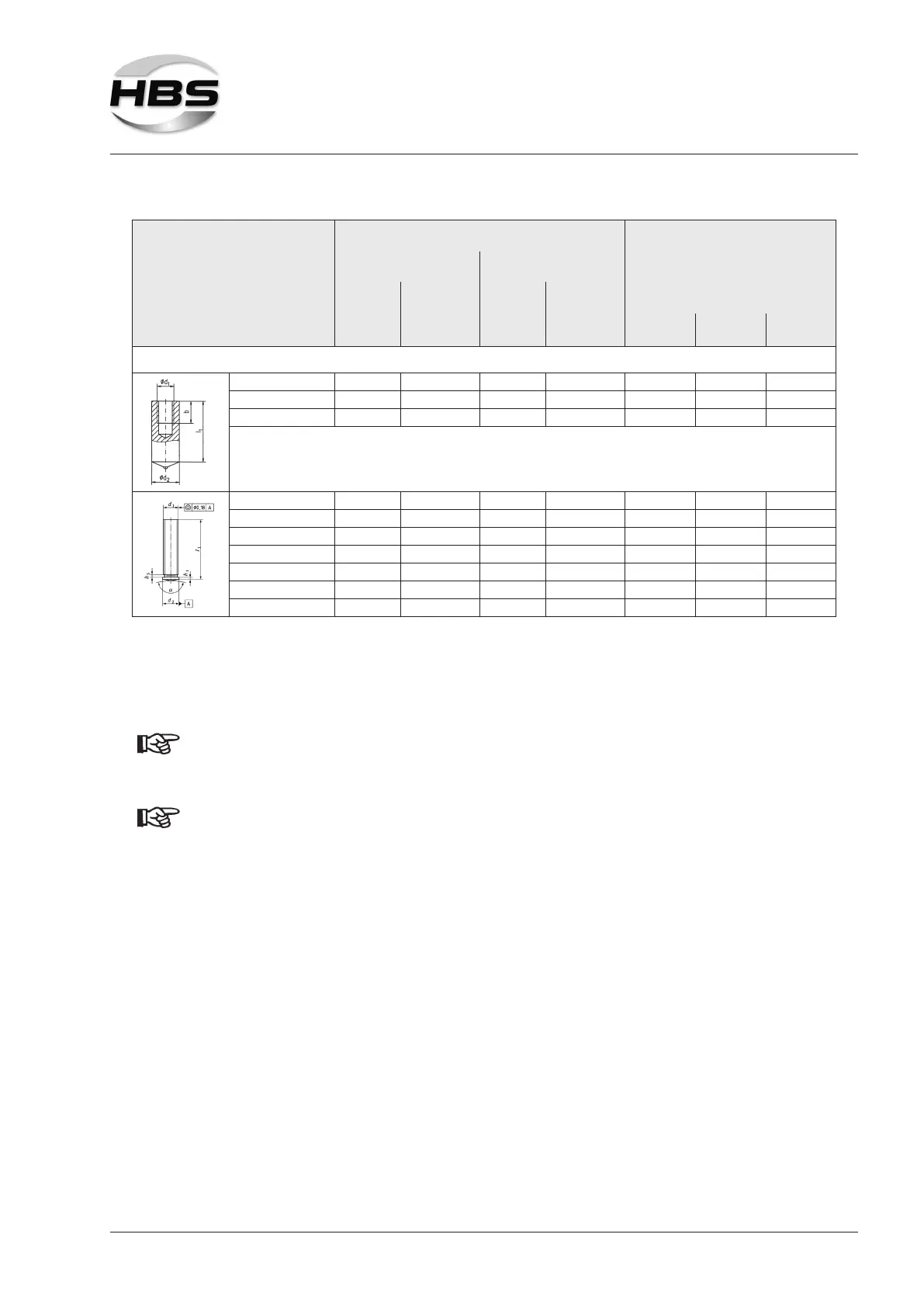

Welding elements

Material:

4.8 (suitable for welding) / A2-50

4)

Diameter of welding elements

ARC 500, ARC 800, ARC 1550,

IT 50, IT 90, IT 130,

IT 1002, IT 2002, IT 3002

metric imperial (US)

Stud

diameter

in mm

eff. diameter

in mm

Stud

diameter

in inches

eff. diameter

in inches

Stud welding gun parameter A 12

4)

Insertion

depth

Lift

Spring

force

Material of workpiece: Mild steel (suitable for welding) / alloyed steel (suitable for welding)

4)

Ø d

1

Ø d

2

Ø d

1

Ø d

2

ID

2)

M6 10 1/4 0.394 3.0 1.4 6

ID

2)

M8 12 5/16 0.472 3.0 1.6 6

Ø d

1

Ø d

2

Ø d

1

Ø d

2

PS (US, IS)

3)

M3 4 1/8 0.157 2.0 1.2 6

PS (US, IS)

3)

M4 5 5/32 0.197 2.0 1.4 6

PS (US, IS)

3)

M5 6 3/16 0.236 2.0 1.4 6

PS (US, IS)

3)

M6 7 1/4 0.276 2.5 1.6 6

PS (US, IS)

3)

M8 9 5/16 0.354 3.0 2.0 6

PS (US, IS)

3)

M10 11 3/8 0.433 3.0 2.4 6

1)

to be checked by test weldings

2)

Information and recommendations on this can be found in DIN EN ISO 14555.

3)

Information and recommendations on this can be found in DVS 0902.

4)

When welding on galvanized workpieces we recommend increasing the lift.

The maximum adjustment values which can be set for the insertion

depth (3.5 mm) as well as the lift (3 mm) should not be exceeded.

The specied values apply for welding in welding position PA.

Loading...

Loading...