©HBS Bolzenschweiss-Systeme GmbH & Co. KG

All rights reserved – Reprinting, in whole or in part, only with the approval of the manufacturer

22

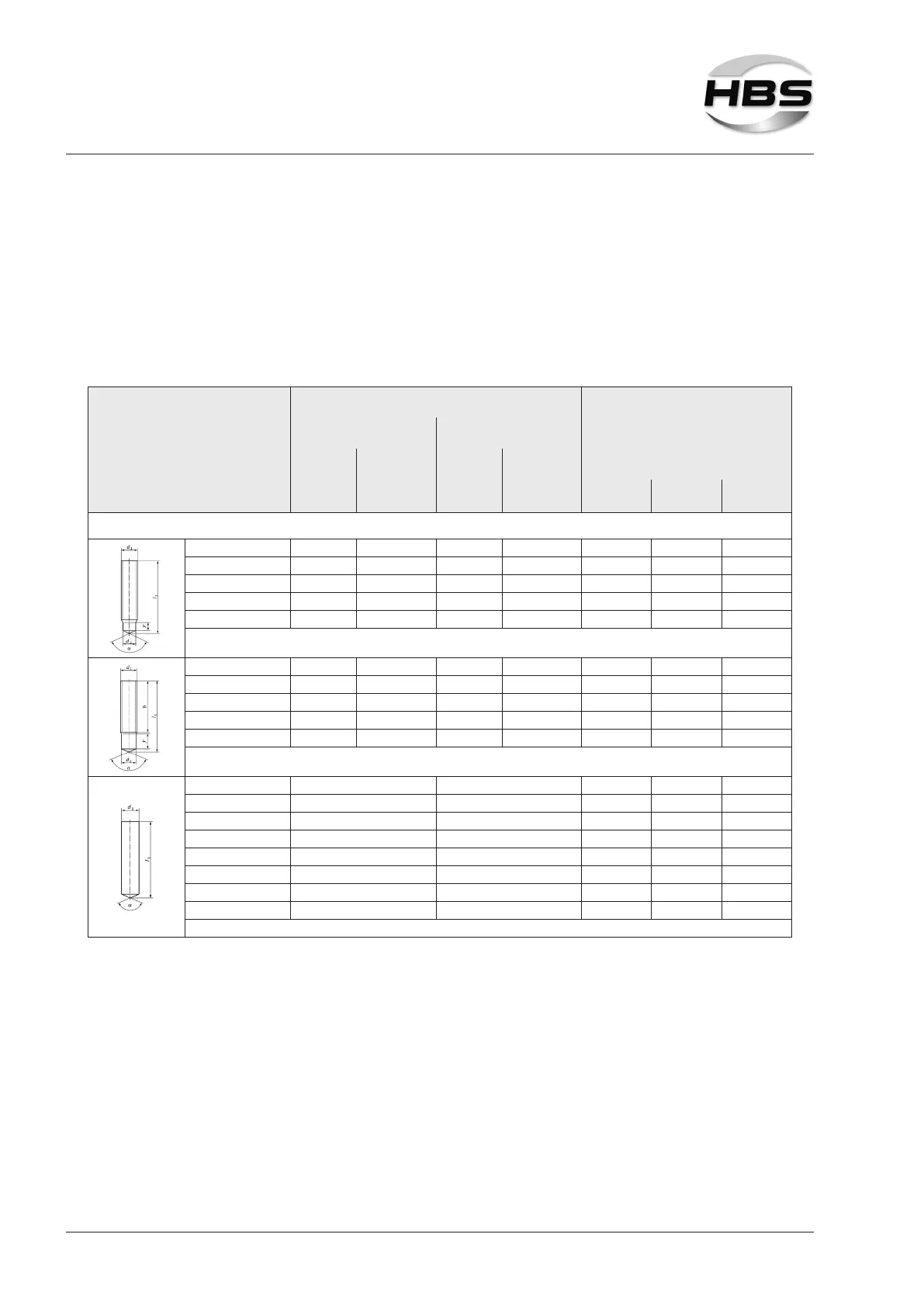

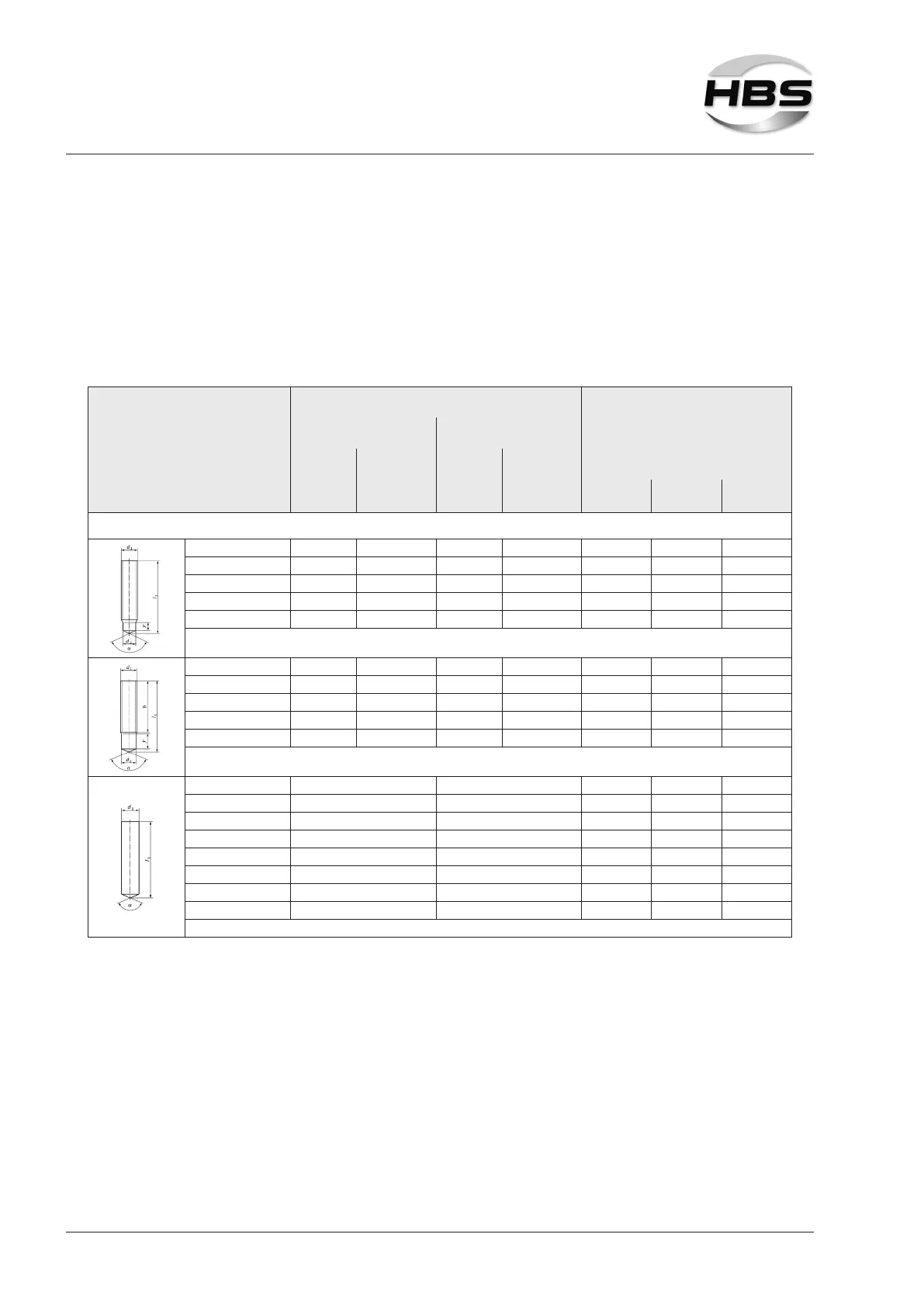

10 Preparing the Stud Welding Gun

10.3 Setting the Welding Parameters

The insertion depth, lift and spring force are, among others, dependent on the work-

piece and welding elements used and their diameters.

The specications in the following table are guidelines.

Select the applicable parameters for insertion depth, lift and spring force for your

workpiece.

Welding elements

Material:

4.8 (suitable for welding) / A2-50

4)

Diameter of welding elements

ARC 500, ARC 800, ARC 1550,

IT 50, IT 90, IT 130,

IT 1002, IT 2002, IT 3002

metric imperial (US)

Stud

diameter

in mm

eff. diameter

in mm

Stud

diameter

in inches

eff. diameter

in inches

Stud welding gun parameter A 12

1)

Insertion

depth

Lift

Spring

force

Material of workpiece: Mild steel (suitable for welding) / alloyed steel (suitable for welding)

4)

Ø d

1

Ø d

2

Ø d

1

Ø d

2

RD (MR)

2)

M6 4.7 1/4 0.185 2.0 1.0 6

RD (MR)

2)

M8 6.2 5/16 0.244 2.0 1.0 6

RD (MR)

2)

M10 7.9 3/8 0.311 2.5 1.2 6

RD (MR)

2)

M12 9.5 1/2 0.374 3.0 1.4 6

Ø d

1

Ø d

2

Ø d

1

Ø d

2

PD/MD (DD)

2)

M6 5.35 1/4 0.211 2.0 1.0 6

PD/MD (DD)

2)

M8 7.19 5/16 0.283 2.5 1.2 6

PD/MD (DD)

2)

M10 9.03 3/8 0.356 3.0 1.4 6

PD/MD (DD)

2)

M12 10.86 1/2 0.428 3.0 1.4 6

Ø d

1

Ø d

1

UD / Pins

2)

3 (ISO) #4 / 12 gage 1.5 1.0 6

UD / Pins

2)

4 (ISO) #8 1.5 1.0 6

UD / Pins

2)

5 (ISO) #10 / 3/16 2.0 1.0 6

UD / Pins

2)

6 1/4 2.0 1.0 6

UD / Pins

2)

8 5/16 2.5 1.2 6

UD / Pins

2)

10 7/16 3.0 1.4 6

UD / Pins

2)

12 1/2 3.0 1.6 6

1)

to be checked by test weldings

2)

Information and recommendations on this can be found in DIN EN ISO 14555.

4)

When welding on galvanized workpieces we recommend increasing the lift.

Loading...

Loading...