31©HBS Bolzenschweiss-Systeme GmbH & Co. KG

All rights reserved – Reprinting, in whole or in part, only with the approval of the manufacturer

12 Troubleshooting

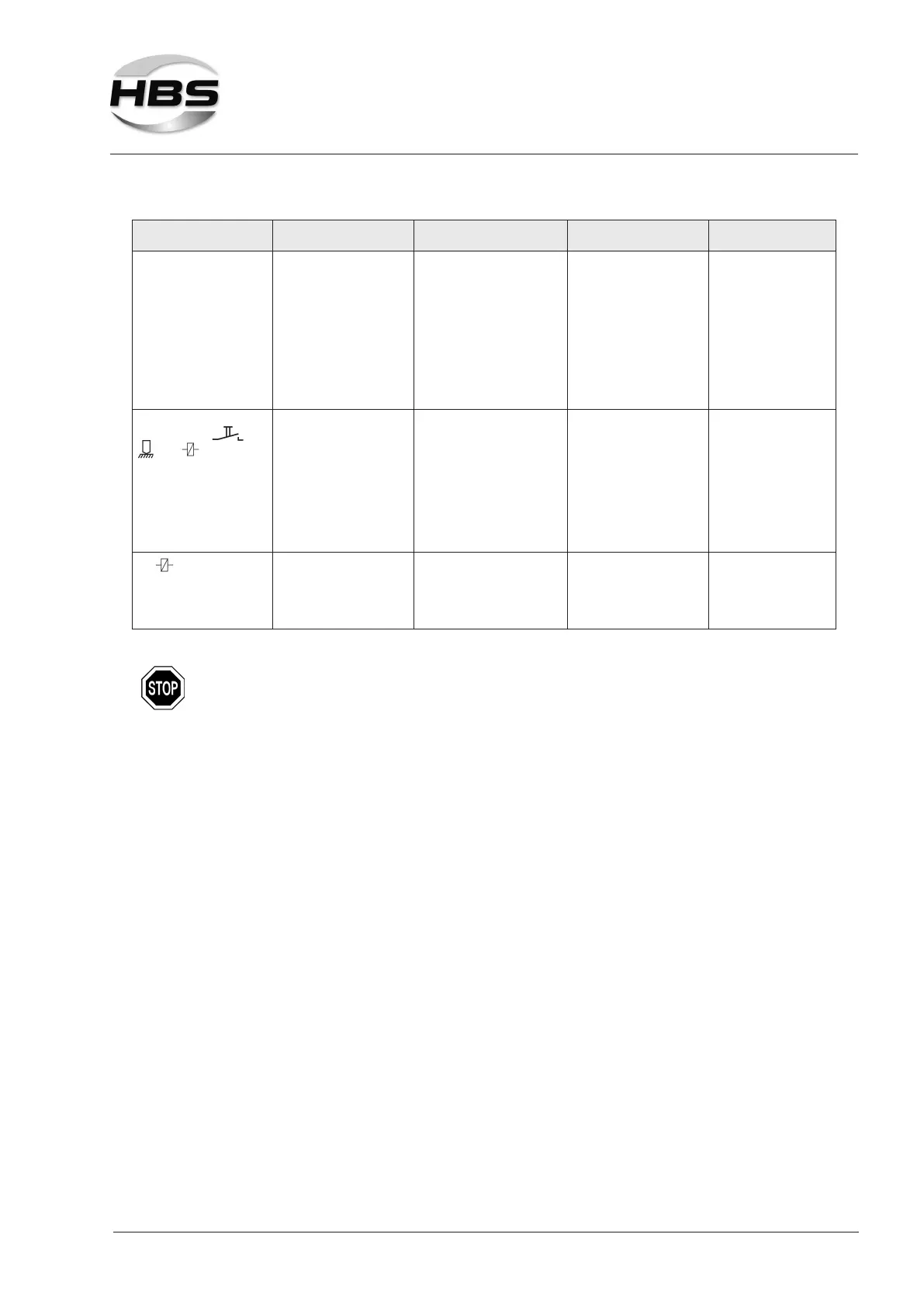

Fault Possible cause Fault localisation Fault remedy Performance

Welding gun does not

weld

Ground connection

defective (no contact

signal on stud welding

unit)

Check, whether ground

cable is connected to

workpiece in a technically

correct way

Connect ground cable Trained personnel

Check ground cable for

electrical ow *)

In case of no ow:

Replace ground

cable *)

Qualied specialists

Stud welding unit

defective

Follow the instructions

of the connected stud

welding unit

Repair required Factory service or

authorised agencies

Welding gun does not

lift, in spite of ,

and

No lift adjusted Check adjusted parame-

ters on welding gun

Change adjusted para-

meters

Trained personnel

Short circuit of magne-

tic circuit of the welding

gu

Meassure resistance

value at control cable

connector (18 Ω to 22 Ω)

between Pin 1 and

Pin 2 *)

Replace control cable

connector, control cable

and solenoid *)

Qualied specialists

Solenoid defective Meassure solenoid (18 Ω

to 22 Ω) *)

Replace solenoid *) Qualied specialists

No display

Magnetic circuit inter-

rupted

Meassure resistance

value at control cable

connector (18 Ω to 22 Ω)

between Pin 1 and

Pin 2 *)

Replace solenoid or

control cable *)

Qualied specialists

Work marked with *) may only be carried out by qualied electricians!

Please contact our Service department if none of the measures described

remedies the situation.

Please use the form „Service & Repair“ in the annex to send in the stud

welding unit or stud welding gun.

Loading...

Loading...