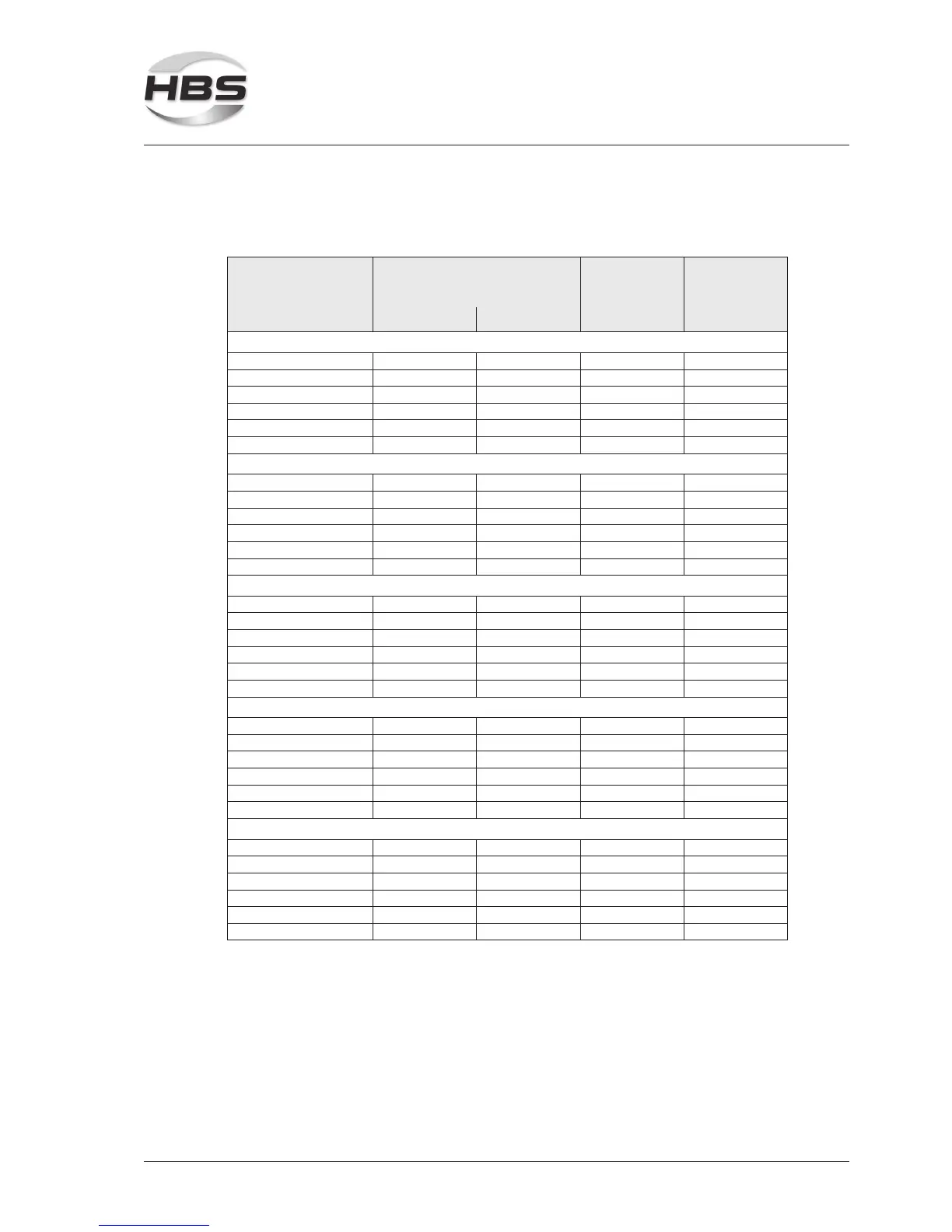

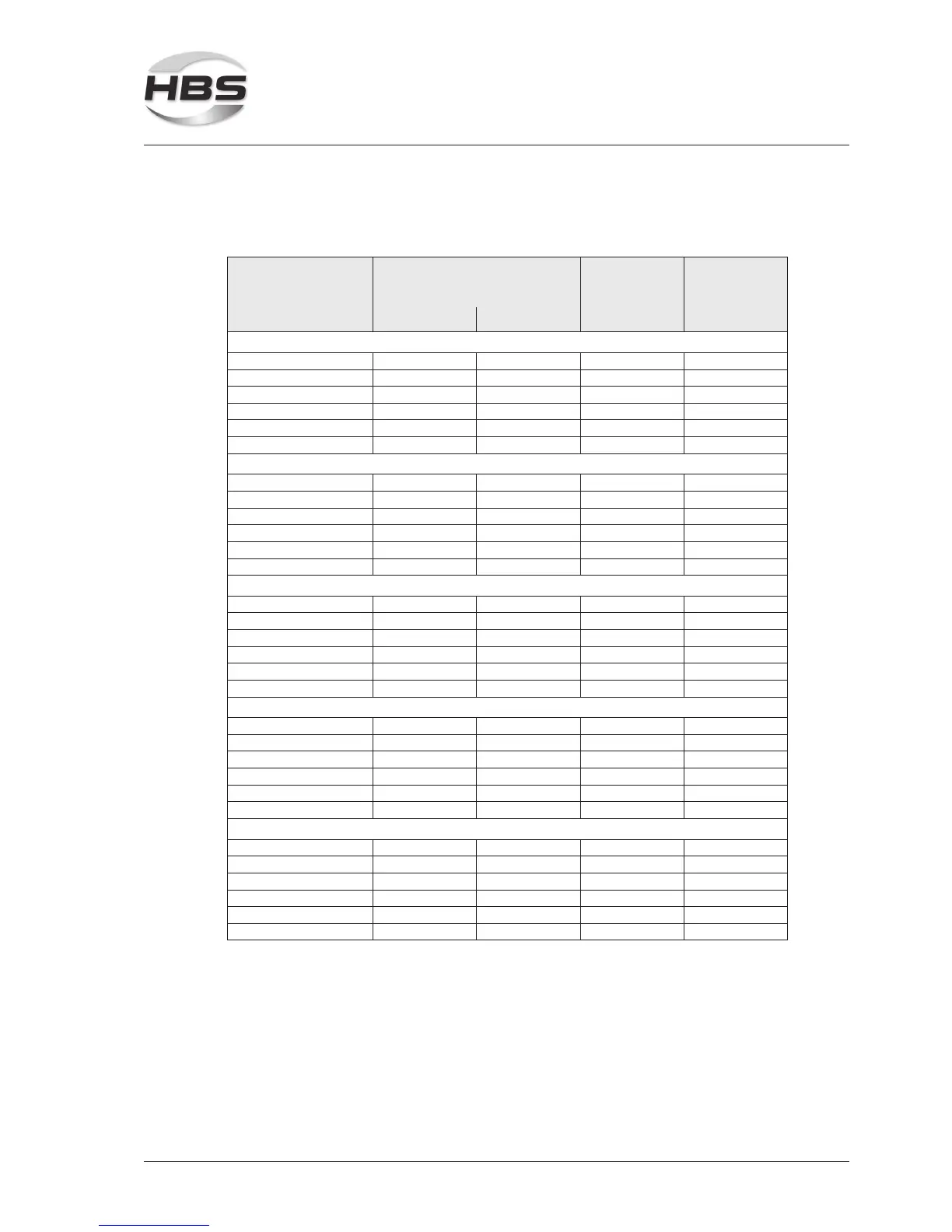

Determining the Charging Voltage for the Welding Guns C 08 and CA 08

Material

of welding elements

Diameter of welding elements

Charging

voltage

1)

CDi 2302

in V

Welding rate

4)

in studs/min

metric

PT, UT IT

Material of workpiece: Mild steel (suitable for welding)

4.8 (suitable for welding) M3, 3 mm -- 60 33

4.8 (suitable for welding) M4, 4 mm -- 80 30

4.8 (suitable for welding) M5, 5 mm 5 mm, M3 100 24

4.8 (suitable for welding) M6, 6 mm 6 mm, M4 130 17

4.8 (suitable for welding) M8, 7.1 mm 7.1 mm, M5 170 12

4.8 (suitable for welding) M10, 10 mm

6) 6)

220

2) 6)

9

Material of workpiece: Galvanised steel (suitable for welding)

4.8 (suitable for welding) M3, 3 mm -- 80 30

4.8 (suitable for welding) M4, 4 mm -- 120 18

4.8 (suitable for welding) M5, 5 mm 5 mm, M3 170 12

4.8 (suitable for welding) M6, 6 mm 6 mm, M4 210 9

4.8 (suitable for welding) M8, 7.1 mm 7.1 mm, M5 -- --

4.8 (suitable for welding) M10, 10 mm

6) 6)

-- --

Material of workpiece: Alloyed steel (suitable for welding)

A2-50 M3, 3 mm -- 60 33

A2-50 M4, 4 mm -- 70 31

A2-50 M5, 5 mm 5 mm, M3 90 26

A2-50 M6, 6 mm 6 mm, M4 130 17

A2-50 M8, 7.1 mm 7.1 mm, M5 170 12

A2-50 M10, 10 mm

6) 6)

210

2) 6)

9

Material of workpiece: Alloyed steel (suitable for welding)

CuZn37 M3, 3 mm -- 60 33

CuZn37 M4, 4 mm -- 70 31

CuZn37 M5, 5 mm 5 mm, M3 100 24

CuZn37 M6, 6 mm 6 mm, M4 150 14

CuZn37 M8, 7.1 mm 7.1 mm, M5 220 9

CuZn37 M10, 10 mm

6) 6)

-- --

Material of workpiece: Aluminium

AlMg3 M3, 3 mm -- 60 33

AlMg3 M4, 4 mm -- 80 30

AlMg3 M5, 5 mm 5 mm, M3 100 24

AlMg3

5)

M6, 6 mm 6 mm, M4 140

3)

15

AlMg3

5)

M8, 7.1 mm

5)

7.1 mm, M5

5)

-- --

AlMg3

5)

M10, 10 mm

5) 6) 5) 6)

-- --

1)

to be checked by test weldings

2)

only in combination with welding gun C 08 possible

3)

only in combination with welding gun CA 08 possible

4)

ambient temperature: 20 °C

5)

Due to the material characteristics of Aluminium and the corresponding limitations regarding the process stabili-

ty a maximum stud diameter of 6 mm is recommended.

6)

Welding element is not standardized according to DIN EN ISO 13918, but manufactured by the manufacturer‘s

discretion. The welding parameters should be determined by test weldings.

Loading...

Loading...