Page 12

STEP-BY-STEP ASSEMBLY

MECHANICAL

ASSEMBLY

Refer to Pictorial

1

for the following steps.

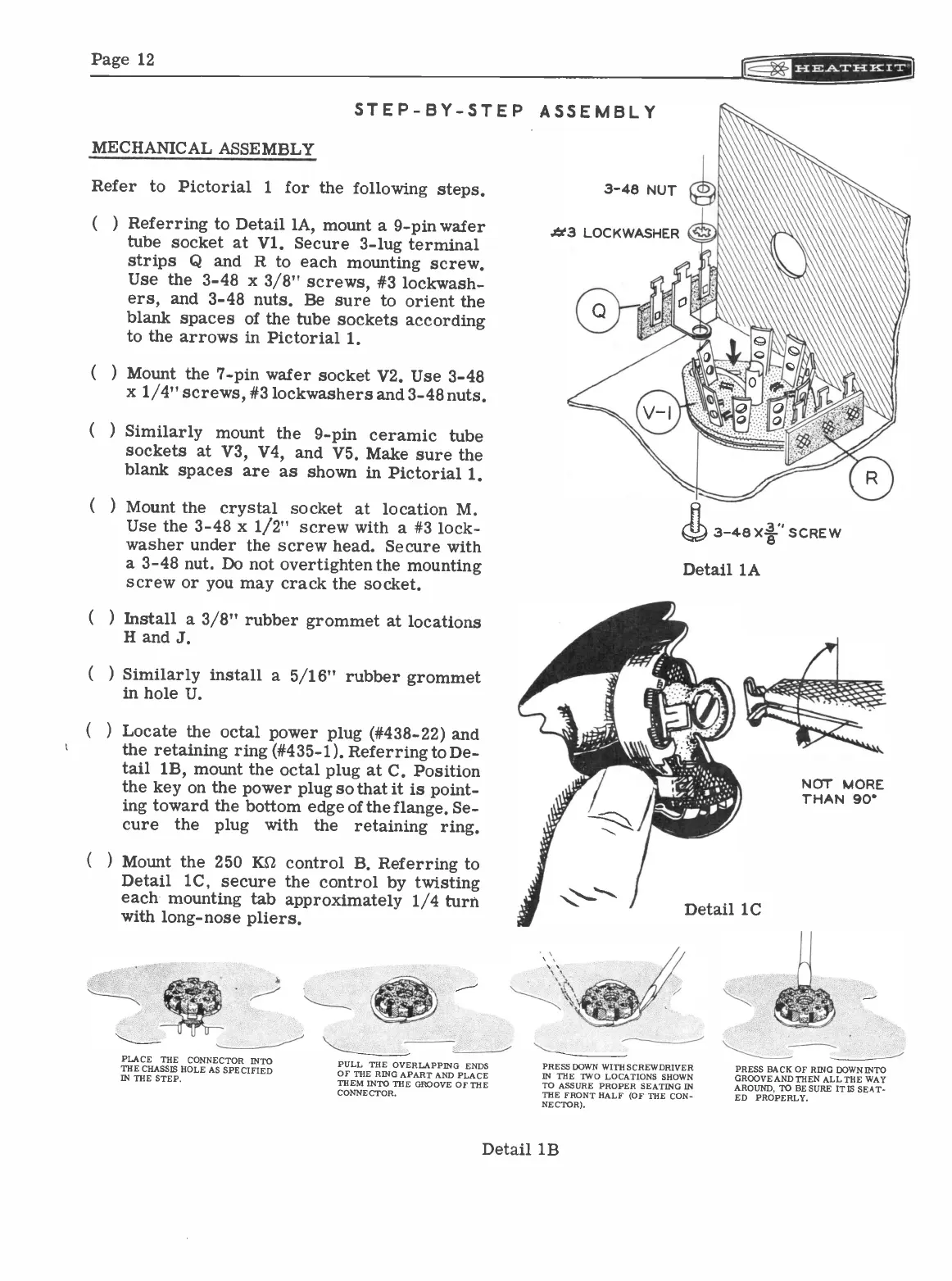

( Referring to Detail 1A, mount a 9 -pin wafer

tube socket at Vl. Secure 3 -lug terminal

strips Q and R to each mounting screw.

Use the 3-48 x 3/8" screws, #3 lockwash-

ers, and 3-48 nuts. Be sure to orient the

blank spaces of the tube sockets according

to the arrows in Pictorial 1.

(

) Mount the 7 -pin wafer socket V2.

Use 3-48

x 1/4" screws, #3 lockwashers and 3-48 nuts.

(

) Similarly mount the

9 -pin ceramic tube

sockets at V3, V4, and V5. Make

sure the

blank spaces are as shown in Pictorial 1.

(

) Mount the

crystal socket at location M.

Use the 3-48 x 1/2" screw with a #3 lock

-

washer under the screw head. Secure with

a 3-48 nut. Do not overtighten the mounting

screw or you may crack the socket.

) Install a 3/8" rubber grommet at locations

H and J.

(

) Similarly install a 5/16" rubber

grommet

in hole U.

(

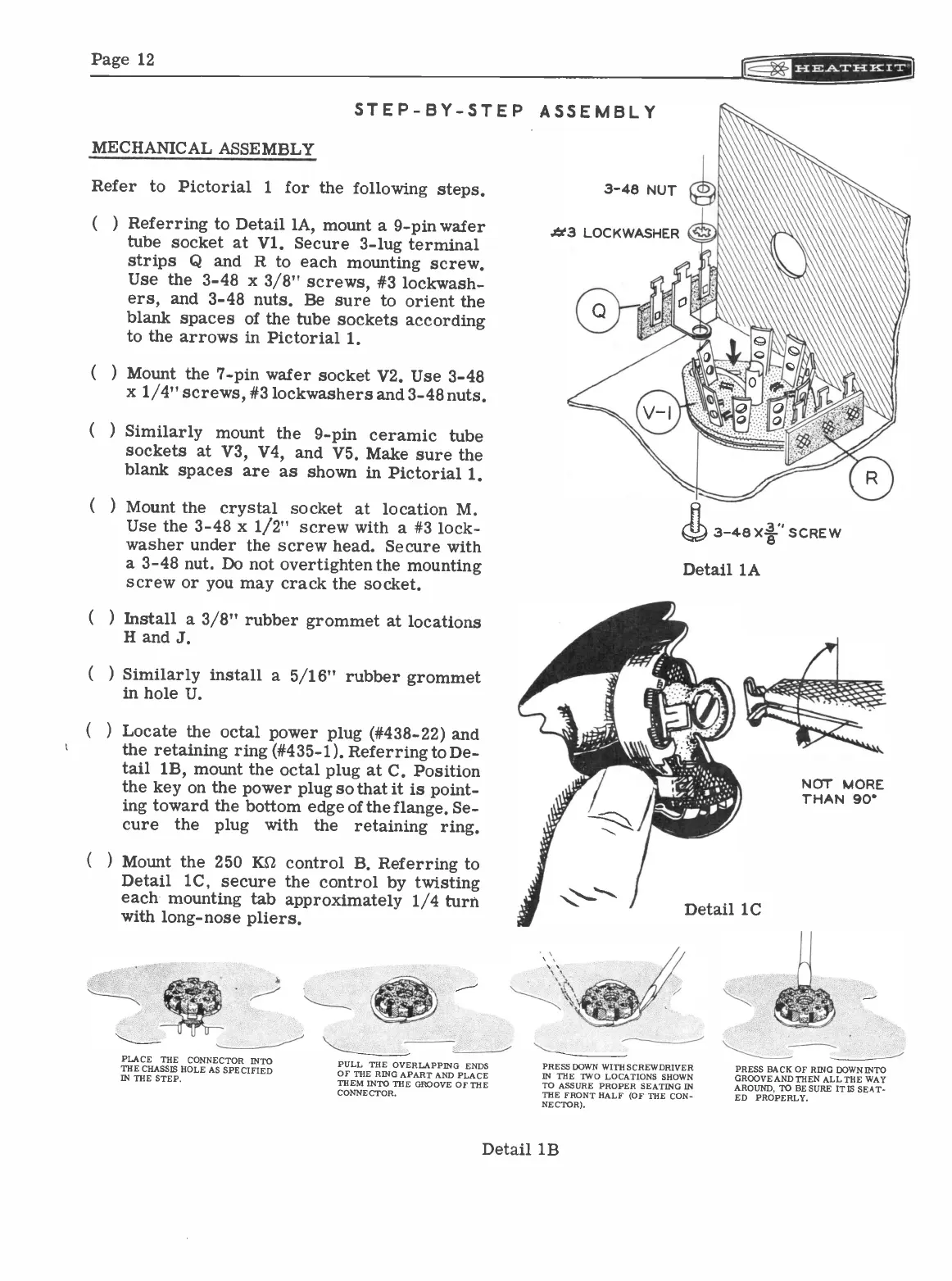

) Locate the octal power plug (#438-22)

and

the retaining ring (#435-1). Referring to De-

tail 1B, mount the octal plug at C. Position

the key on the power plug so that it is point-

ing toward the bottom edge of the flange. Se-

cure

the

plug with the

retaining ring.

(

) Mount the 250 KEZ control B. Referring to

Detail 1C, secure the control by twisting

each mounting tab approximately 1/4 turn

with long -nose pliers.

PLACE THE CONNECTOR INTO

THE CHASSIS HOLE AS SPECIFIED

IN THE STEP.

PULL THE OVERLAPPING ENDS

OF TEE RING APART AND PLACE

THEM INTO THE GROOVE OF THE

CONNECTOR.

Alt3 LOCKWASHER

(11)

3-48X* SCREW

Detail

lA

Detail 1C

PRESS DOWN WITH SCREWDRIVER

IN THE TWO LOCATIONS SHOWN

TO ASSURE PROPER SEATING IN

THE FRONT HALF (OF THE CON-

NECTOR).

Detail 1B

NOT MORE

THAN 90'

PRESS BACK OF RING DOWN INTO

GROOVE AND THEN ALL THE WAY

AROUND, TO BE SURE IT IS SEAT-

ED PROPERLY.

Loading...

Loading...