41 / 56

PL

SK

DE

EN

CS

HU

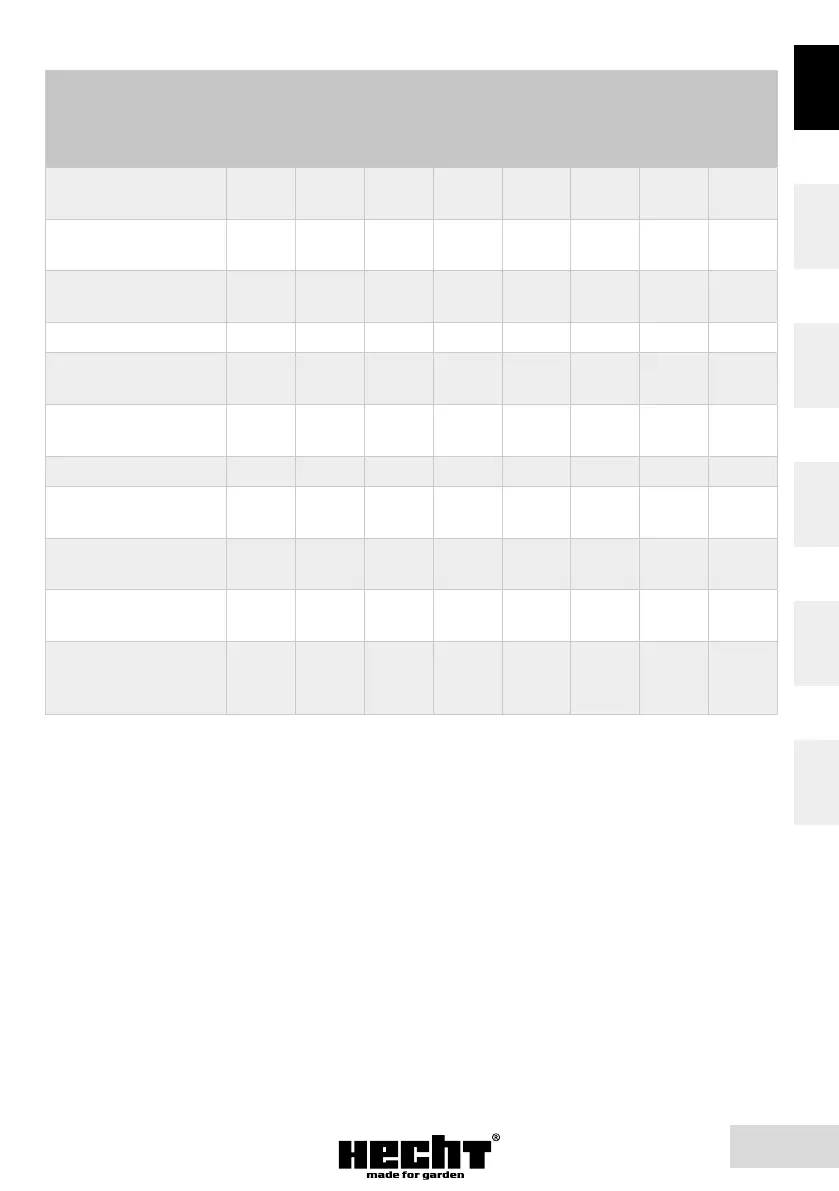

INSPECTION SCHEDULE FOR SAFETY OPERATION

Activity

After oper.

After first 5

operation

hours

Daily or

every 5

hours

25 h

50 h

Strart of

season

End of

season

As necess.

Check fastening of

all nuts

Lubricating moving

parts

Inspection of

coupling

Check engine oil

Replacement of

engine oil ***

Inspection of spark

plug

Cleaning spark plug*

Replacement of

spark plug *

Clean surrounding of

muffler

Check fuel hose

condition

Inspection of

carburetor

adjustment **

Marked items:

* See the instructions

** These operations must be done in authorised service cente

*** First change of engine oil after 5 operation hours, at operations with high load follows

change after 25 operating hours

MACHINE MAINTENANCE

• Keep the machine in good condition

• Careful handling and regular cleaning ensure that the machine remains functional and

efficient for a long time.

• Keep all nuts, bolts and screws tight to be sure the equipment is in safe working condition.

• To reduce the fire hazard, keep the engine, silencer and petrol storage area free of all debris

or excessive grease.

• Always ensure that the ventilation openings are kept clear of debris.

• Replace worn or damaged parts for safety. Use only original spare parts.

• If it is necessary to replace safety and instruction labels, replace them.

Loading...

Loading...