Central ventilation unit – KWL 200/300 W/W ET

Installation and Operating Instructions

ENEN

8

3.3 Technical data

Technical data KWL 200 W/W ET KWL 300 W/W ET

Voltage/frequency 1~ 230 V~/50 Hz ±6 % 1~ 230 V~/50 Hz ±6 %

Rated current – ventilation 1.2 A 2.0 A

Rated current – preheater 4.4 A 4.4 A

Rated current – max. total 1.2 A (5.6 A incl. preheater) 2.0 A (6.4 A incl. preheater)

Electrical preheater (output) 1.0 kW (accessories) 1.0 kW (accessories)

Elec. supply line to subdistribution board NYM-J 3 x 1.5 mm

2

NYM-J 3 x 1.5 mm

2

Max. flow rate V

max

at 100 Pa

166 m

3

/h (KWL 200 W)

193 m

3

/h (KWL 200 W ET)

275 m

3

/h (KWL 300 W)

306 m

3

/h (KWL 300 W ET)

Temperature operating range -20 °C to +45 °C -20 °C to +45 °C

Temperature installation area

+5 °C to +45 °C

(< 90 % RH., non-condensing)

+5 °C to +45 °C

(< 90 % RH., non-condensing)

Protection category IP34 IP34

Protection class I I

Weight

37 kg (KWL 200 W)

41 kg (KWL 200 W ET)

37 kg (KWL 300 W)

41 kg (KWL 300 W ET)

Heat exchanger Plastic Plastic

2

T3

T1

T2

2

1

1

5

1

T6

Externe Fühler

(Raumseitige Installation)

CO2-Fühler

•

Feuchte/Temperaturfühler

•

VOC-Fühler

•

Fortluft

Zuluft

Abluft

Außenluft

Bei Verwendung eines Heizregisters, muss das Rohrsystem 0,5

m vor und nach dem Heizregister

mit temperaturbeständigem bzw. nicht brennbarem Rohr

versehen werden (z.B. Wickelfalzrohr)

Abb. KWL 200/300 W Rechts

(T7)

Rücklauf

WW-Register

T4

F-AB

3

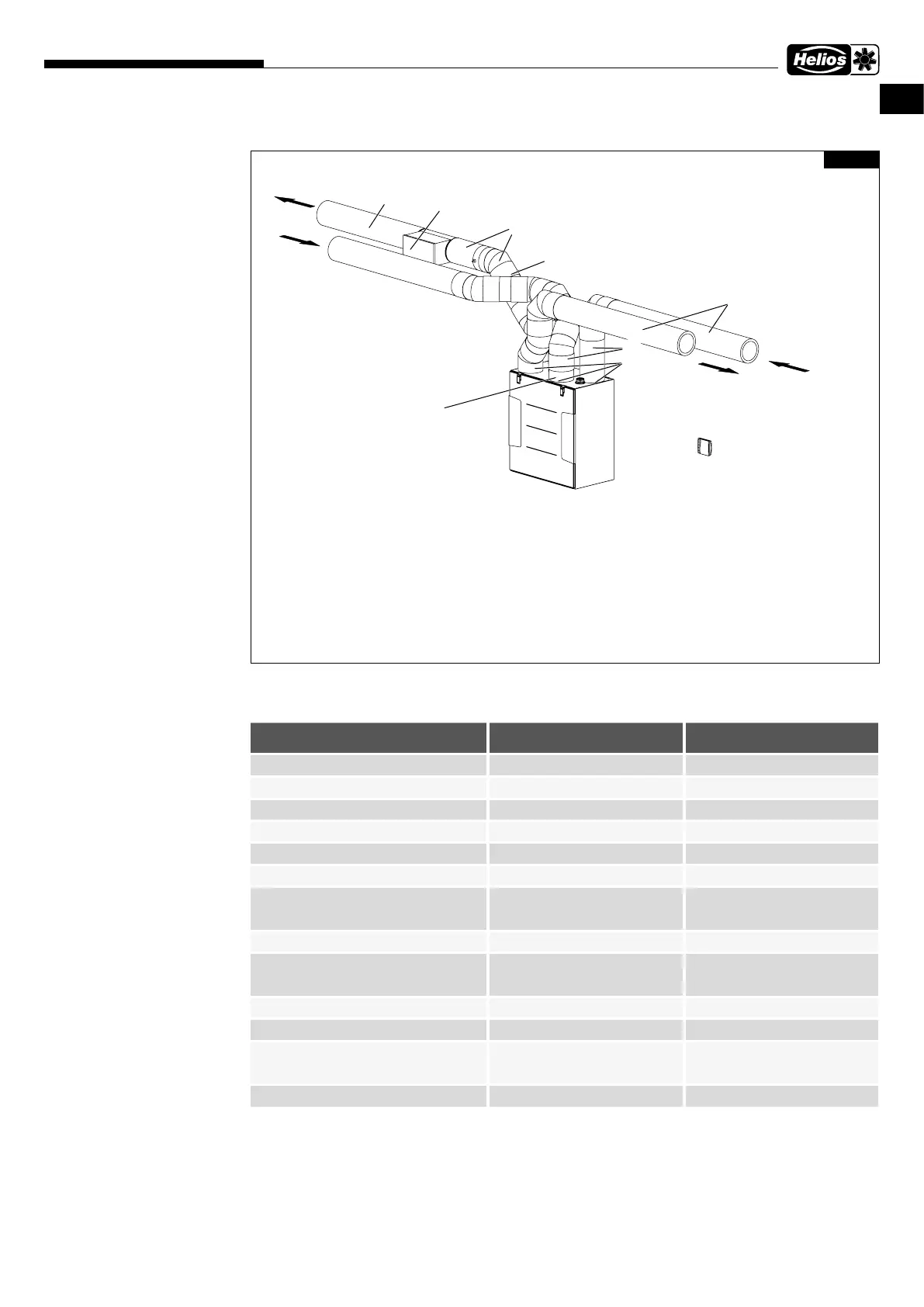

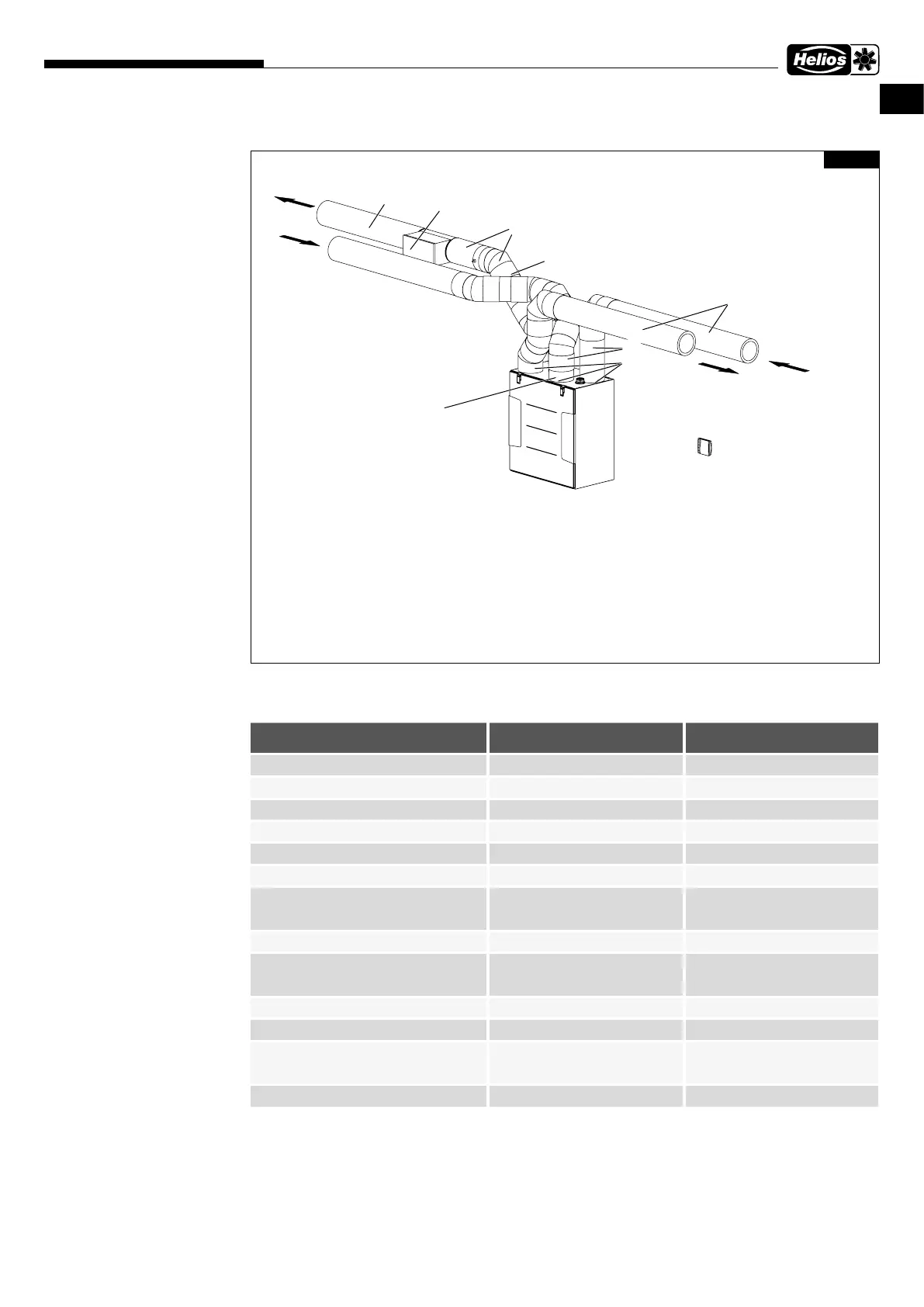

Fig. 2

Non-combustible duct (e.g. spiral duct)

Insulated ducting system IsoPipe

®

Ø125

IP 125/2000 (accessories)

Short duct connector Ø125

RVBD 125 K (accessories)

Electric or warm water heating element

EHR-R 1.2/125 oder WHR 125 (accessories)

Internal humidity sensor

T1 Intake air temperature sensor

T2 Supply air temperature sensor

T3 Extract air temperature sensor

T4 Exhaust air temperature sensor

T6 Air temperature duct sensor

KWL-LTK (accessories)

Supply air

Extract air

Intake air

Exhaust air

External sensor

(Room-side installation)

CO2 sensor

Humidity/temperature sensor

VOC sensor

Fig. KWL 200/300 W Right

Loading...

Loading...