14 Betriebsanleitung_firestar_18-40_Lambda_Englisch_V1.6

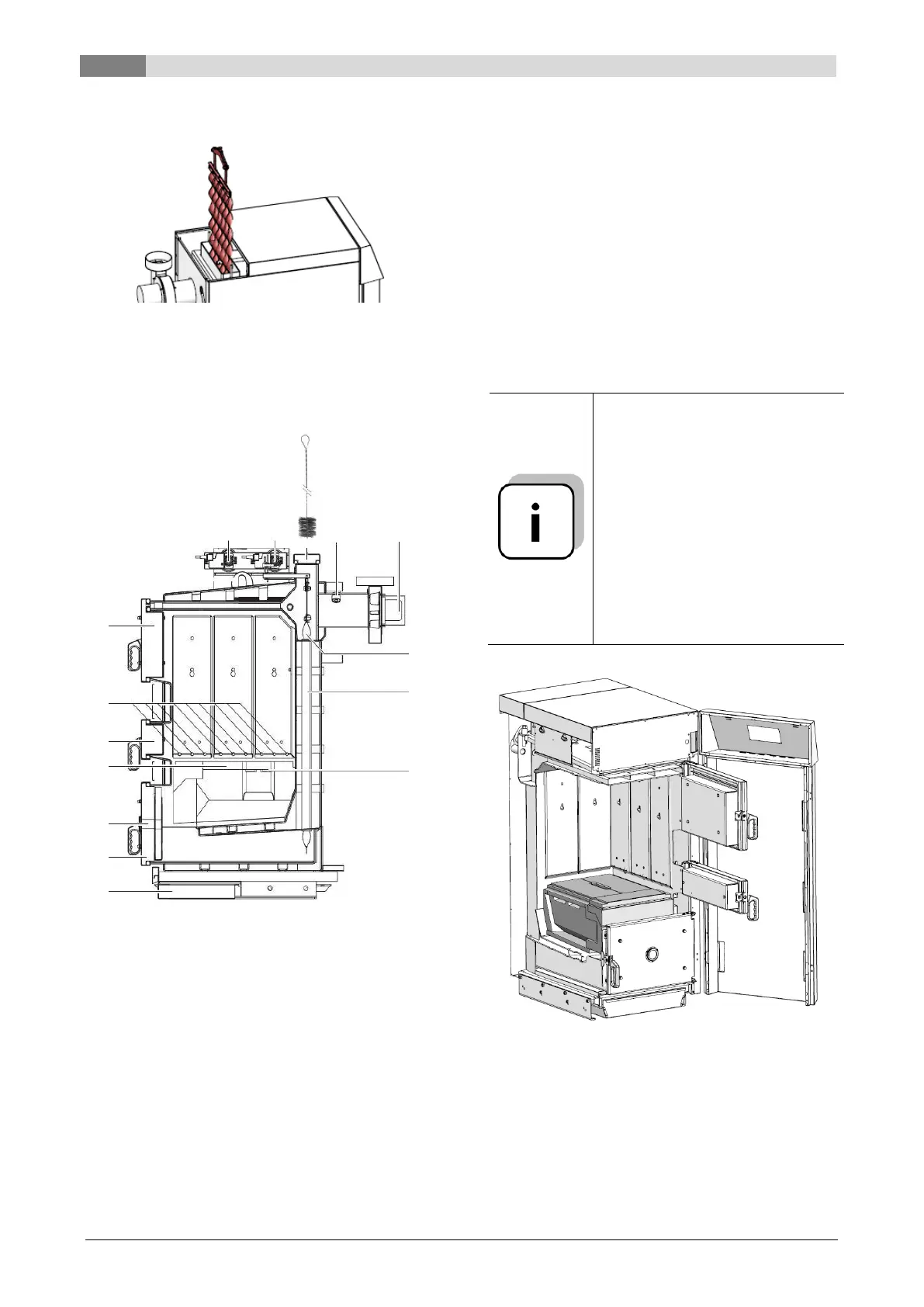

Removing and cleaning of turbulators (13)

Clean the heat exchange pipes with the boiler

brushes (17). Here the ventilator can also be

switched on in order to suck away any dust

forming in the air. This can simply be carried out

in the Unit Off (1) condition in the so-called

aggregate test. (Parameter A04 – ID Fan)

After cleaning

Set the turbulators (13) correctly again,

Put on the cleaning cover (12), tighten the

closing screws and

Install the boiler casing.

The accumulated ash should be removed via the

ash door (7).

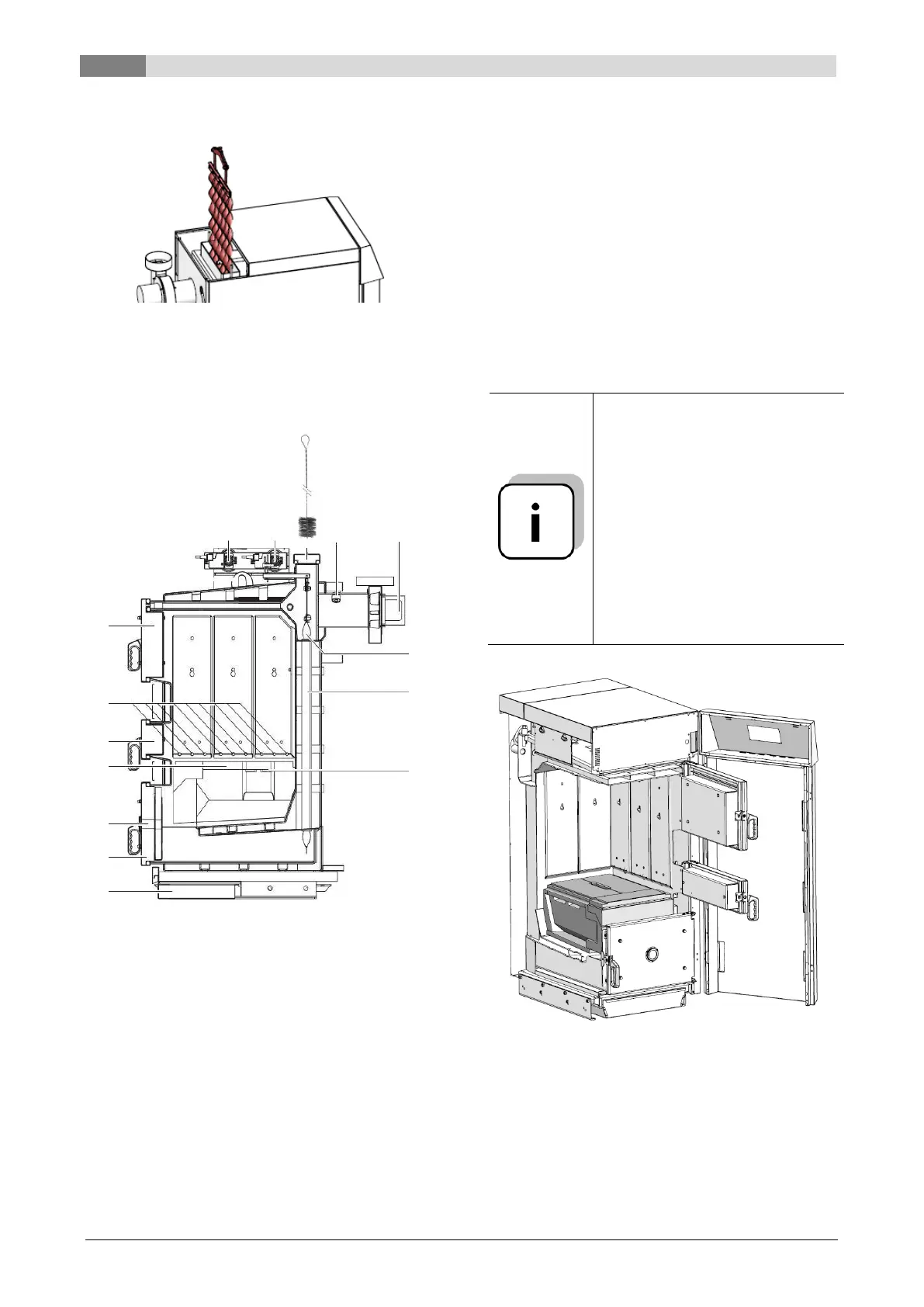

6.3 Cleaning of the combustion

chamber

This only has to be cleaned every two to six days,

depending on the type of fuel used. When burning

fuels with a high proportion of fly ash (e.g. paper,

cardboard, bark, etc.) on combustion, the

combustion chamber should be cleaned more

frequently:

Open the casing door and ash door (7)

Clean the combustion chamber

Keep the primary air feeds (3) clean with

bellows for primary air feeds (19)

Keep the combustion plate inputs clean with

(5) clean with bellows for primary air feeds

(19)

Clean out the combustion tray and

combustion plate using the bellows for the

combustion plate (18)

Close the ash door (7) and casing door

Any elongation fissures on the

insulation plates or combustion

chamber bricks do not affect their

functioning and therefore do not

represent a claim against the

guarantee.

During cleaning ensure that the

slot between the burner plates is

not clogged (see picture below).

On the burner plates themselves,

an ash layer of about 3cm can be

left which is provided for glow

sustainment.

Note:

The combustion chamber must always be cleaned

last, as the ash may fall in the burn-off areas

when cleaning the heat exchanger pipes.

Loading...

Loading...