19

5.2 Explanation

What are wood pellets?

Wood pellets is made of sawdust or shavings.

The used material must not contain foreign

elements, such as glue or varnish, which are

synthetic substances. Under high temperatures

the tree is pressed through a die with holes.

Due to the strong pressure, the chips become

overheated and activate the natural binders of

the wood.

In this way, the pellets maintain their shape

without the addition of any form of binder. The

density of the pellets varies depending on the

type of tree, and it may be 1.5 - 2 times larger

than natural wood.

The cylindrical wood pellets have a diameter

of 6 - 8 mm and a variable length between 10

and 40 mm. Their weight is about 650 kg / m3

because of the low water content (8-10%) they

have a high amount of energy.

Heta A/S recommends using ENplus -A1 quality pellets to get the most out of their pellet stove.

The pellets must be transported unconditionally

and stored dry. If they come into contact with

moisture, they swell very much and thus become

useless. Therefore, they must be protected

against moisture during transport and storage.

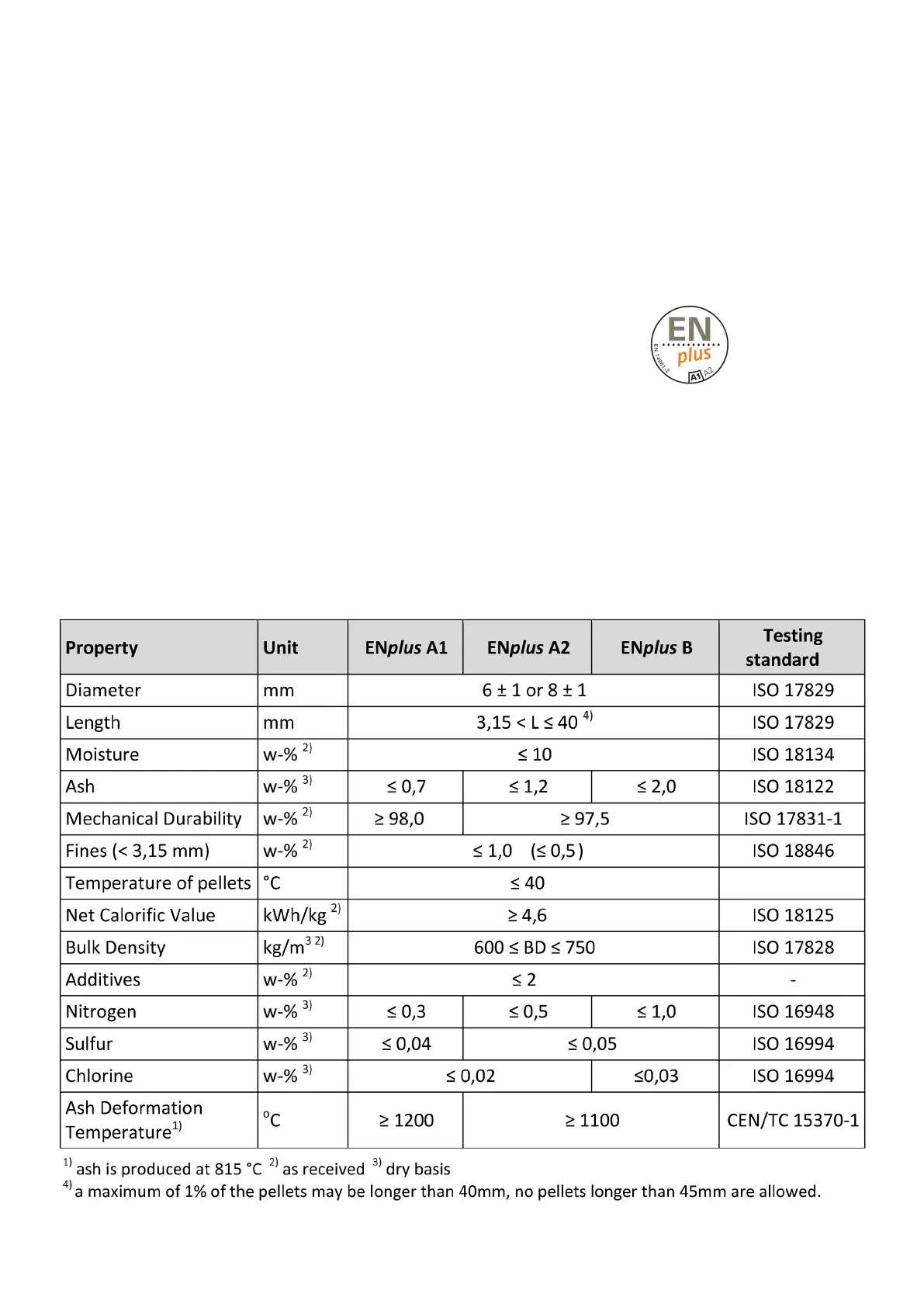

Quality Classes:

The ENplus certification scheme defines three

pellet quality classes. They are based on the

classes of ISO 17225-2 and are named:

a. ENplus -A1

b. ENplus -A2

c. EN -B

The types of wood indicated in Table 2 can be

used according to the standard ISO 17225-2 as

raw material for the production of wood pellets.

The raw material assortments are defined in

ISO 17225-1.

The table below provides an overview of pellet

properties and the related threshold values

Loading...

Loading...