18 English 2171411

*2171411*

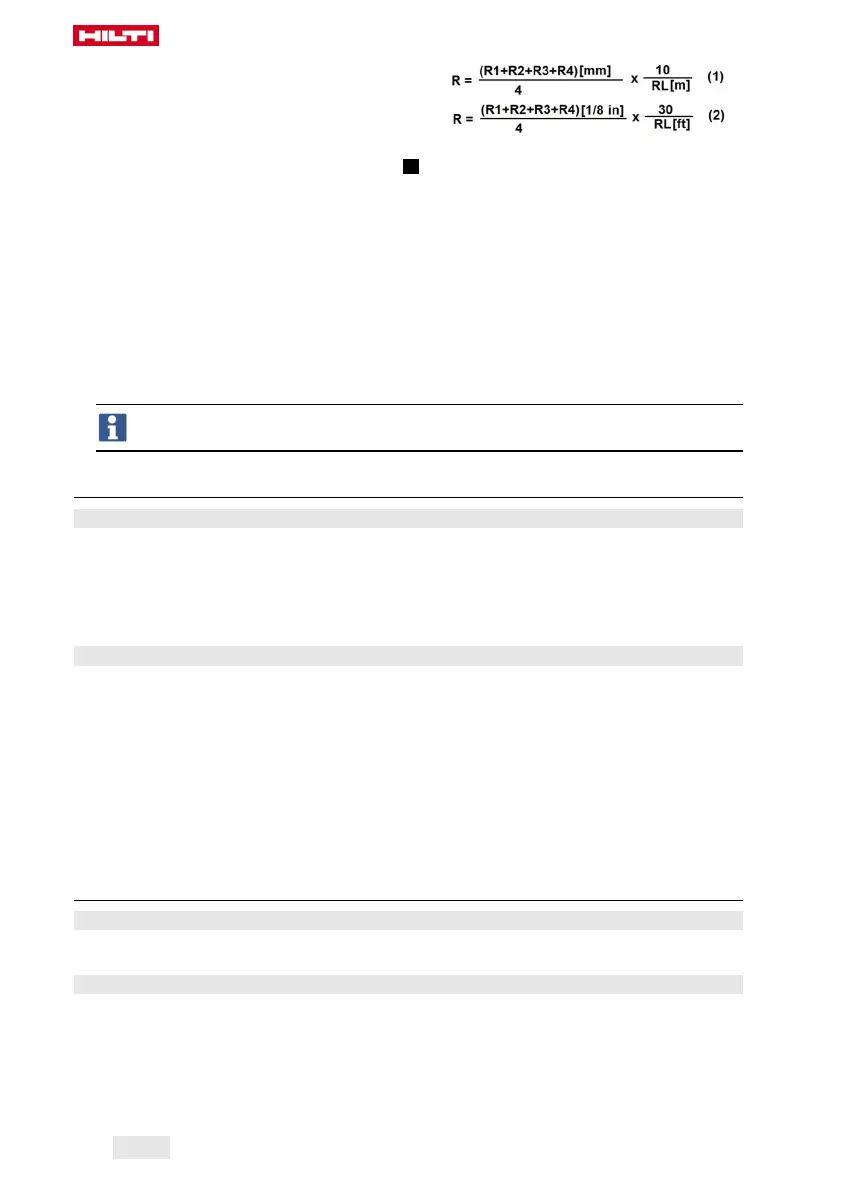

5. Calculate the offset R (RL = room length).

▶ The value R should be less than 3 mm or 1/8".

5.8.4 Checking the accuracy of the vertical line 14

1. Position the tool at a height of 2 m (pos.1).

2. Switch the tool on.

3. Position the first target plate T1 (vertical) at a distance of 2.5 meters from the tool at the same height (2

meters), so that the vertical laser beam strikes the plate. Mark this position.

4. Then place the second target plate T2 at a position 2 meters below the first target plate, so that the

vertical laser beam strikes the plate. Mark this position.

5. Mark position 2 at the opposite side of the test setup (mirror image) on the laser line on the floor at a

distance of 5 meters from the tool.

6. Now place the tool on the previously marked position (pos. 2) on the floor.

7. Align the laser beam so that it strikes the target plate T1 and the position marked on it.

8. Mark the new position on target plate T2.

9. Read the distance D between the two marks on target plate T2.

If the difference D is greater than 2 mm, the tool must be returned to a Hilti repair center for

adjustment.

6 Care and maintenance

6.1 Cleaning and drying

▶ Blow any dust off the glass.

▶ Do not touch the glass surfaces with your fingers.

▶ Use only a soft, clean cloth to clean the tool. If necessary, moisten the cloth with a little alcohol or water.

▶ Observe the temperature limits when storing your equipment. This is particularly important in summer or

winter if the equipment is kept inside a motor vehicle (-25°C to 63°C / -13°F to 145°F).

6.2 Hilti Calibration Service

We recommend that the tool is checked by the Hilti Calibration Service at regular intervals in order to verify

its reliability in accordance with standards and legal requirements.

Use can be made of the Hilti Calibration Service at any time. Calibration at least once a year is recommended.

The Hilti Calibration Service provides confirmation that the device is in conformance, on the day it is tested,

with the specifications given in the operating instructions.

The tool will be readjusted if deviations from the manufacturer’s specification are found.

After checking and adjustment, a calibration sticker applied to the tool and a calibration certificate provide

written verification that the tool operates in accordance with the manufacturer’s specification.

Calibration certificates are always required by companies certified according to ISO 900X.

Your local Hilti contact will be pleased to provide further information.

7 Transport and storage

7.1 Transport

▶ Use the Hilti shipping box or packaging of equivalent quality for transporting or shipping your equipment.

7.2 Storage

▶ Remove the tool from its case if it has become wet.

▶ The tool, its carrying case and accessories should be cleaned and dried (at maximum 63 °C/145 °F).

▶ Repack the equipment only once it has dried completely and then store it in a dry place.

▶ Check the accuracy of the equipment before it is used after a long period of storage or transportation.

Loading...

Loading...