4.2 Troubleshooting the Air Compressor

Most likely problems, causes, and remedies are described below.

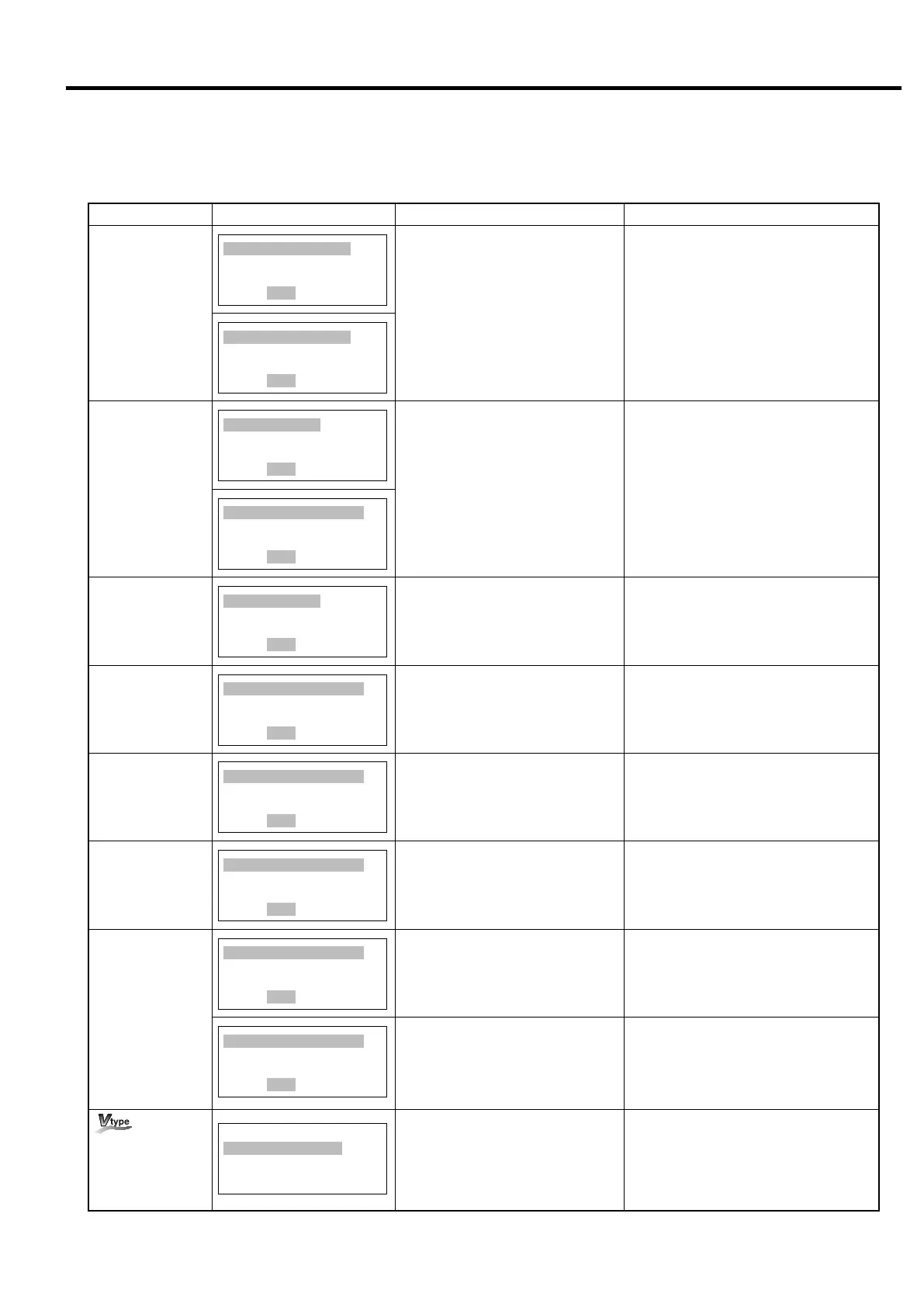

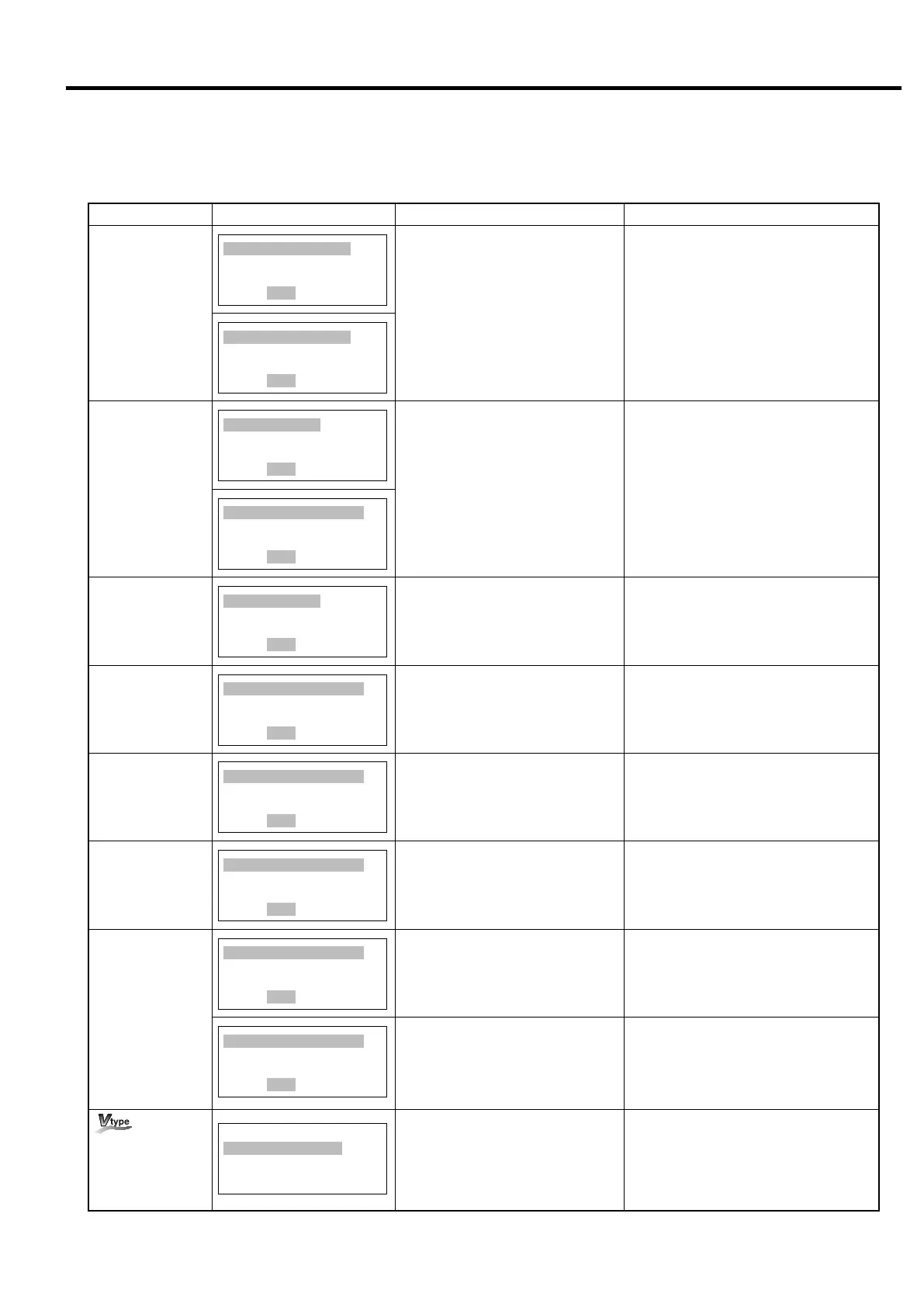

Causes LCD Indication Causes Corrective Remedies

The DSP motor

does not start.

<P R O B L E M>

CONNECTION ERR: REV

Press

RES

after CHK.

1. Power supply switch - Off

2. Power - Failed

3. Power cord - In a reversal phase

connection

4. Power cord - In a phase-lacking

connection

1. Check the main breaker.

2. Check the power supply.

3. Change 2 of 3 wires of the power

cord.

4. Reconnect the power cord tightly and

check the power supply.

NOTE: Phase-lacking is detectable only

when connecting the power.

<P R O B L E M>

CONNECTION ERR: OPEN

Press

RES

after CHK.

Shutdown –

1st-stage dis-

charge air tem-

perature and/ or

pressure too high

<A L A R M>

DIS. TEMP.1:

Press

RES

after CHK.

1. 2nd-stage AIR END air intake effi -

ciency - Lowered

2. Air intake fi lter - Dirty

3. Temperature of Suction Air-High

1. Contact your Hitachi distributor.

2. Clean the air intake fi lter.

3. Lower the suction air temperature.

<S H U T D O W N>

HIGH DIS. TEMP:

Press

RES

after CHK.

Shutdown –

2nd-stage dis-

charge air tem-

perature too high

<A L A R M>

DIS. TEMP.2:

Press

RES

after CHK.

1. Check valve – Compressed air

leaked (from the aftercooler to the

air end when the DSP unloads)

2. Suction throttle valve - Dirty

1. Replace the check valve.

2. Clean the Suction throttle valve.

Note: For information about the Suction

bypass valve, see page 29.

Shutdown –

2nd-stage suction

air temperature

too high

<S H U T D O W N>

2ND SUCT. TEMP:

Press

RES

after CHK.

1. Cooling water pump – Failed, or

Cooling water pressure – Fluctuating

2. Intercooler – Dirty

1. Check the cooling water system.

2. Clean the intercooler

Shutdown –

Oil temperature

too high

<S H U T D O W N>

OIL : HIGH TEMP

Press

RES

after CHK.

1. Oil cooler – Dirty

2. Room temperature – High

3. Oil temperature control valve –

Failed

1. Check the oil cooler.

2. Reduce the room temperature.

3. Check the oil temperature control

valve.

Shutdown –

Oil pressure too

low

<S H U T D O W N>

OIL : LOW TEMP

Press

RES

after CHK.

1. Oil strainer and/or oil fi lter – Dirty

2. Oil level – Low

1. Clean the oil strainer

2. Replace the oil fi lter.

3. Add the oil.

Shutdown –

Main motor and/

or ancillary motor

overloading

<S H U T D O W N>

OVERLOAD : MAIN

Press

RES

after CHK.

1. Power supply voltage – Low

2. Discharge air pressure – Too high

1. Rectify the power supply voltage.

2. Check the suction throttle valve

3. Check the capacity control system.

<S H U T D O W N>

OVERLOAD : SUB

Press

RES

after CHK.

1. Power supply voltage – Low

2. Cooling fan motor – Failed

1. Rectify the power supply voltage.

2. Check the cooling fan motor.

(Measure insulation resistance etc.)

Shutdown

–

Inverter tripping/

restarting

<F A I L U R E>

SYSTEM RETRY :

1.

Power supply voltage – Low or in unbalance

2. Discharge air pressure – Too high

3. Main motor – Overloading

NOTE:‘ INVERTER RESTART’ means that the DSP

shutdowns when the inverter repeats a

restarting action within 1 minute.

1. Rectify the power supply voltage.

2. Check the capacity control system.

3. Measure insulation resistance etc. or

check the main motor.

35

4. TROUBLESHOOTING [Troubleshooting the Air Compressor]

Loading...

Loading...