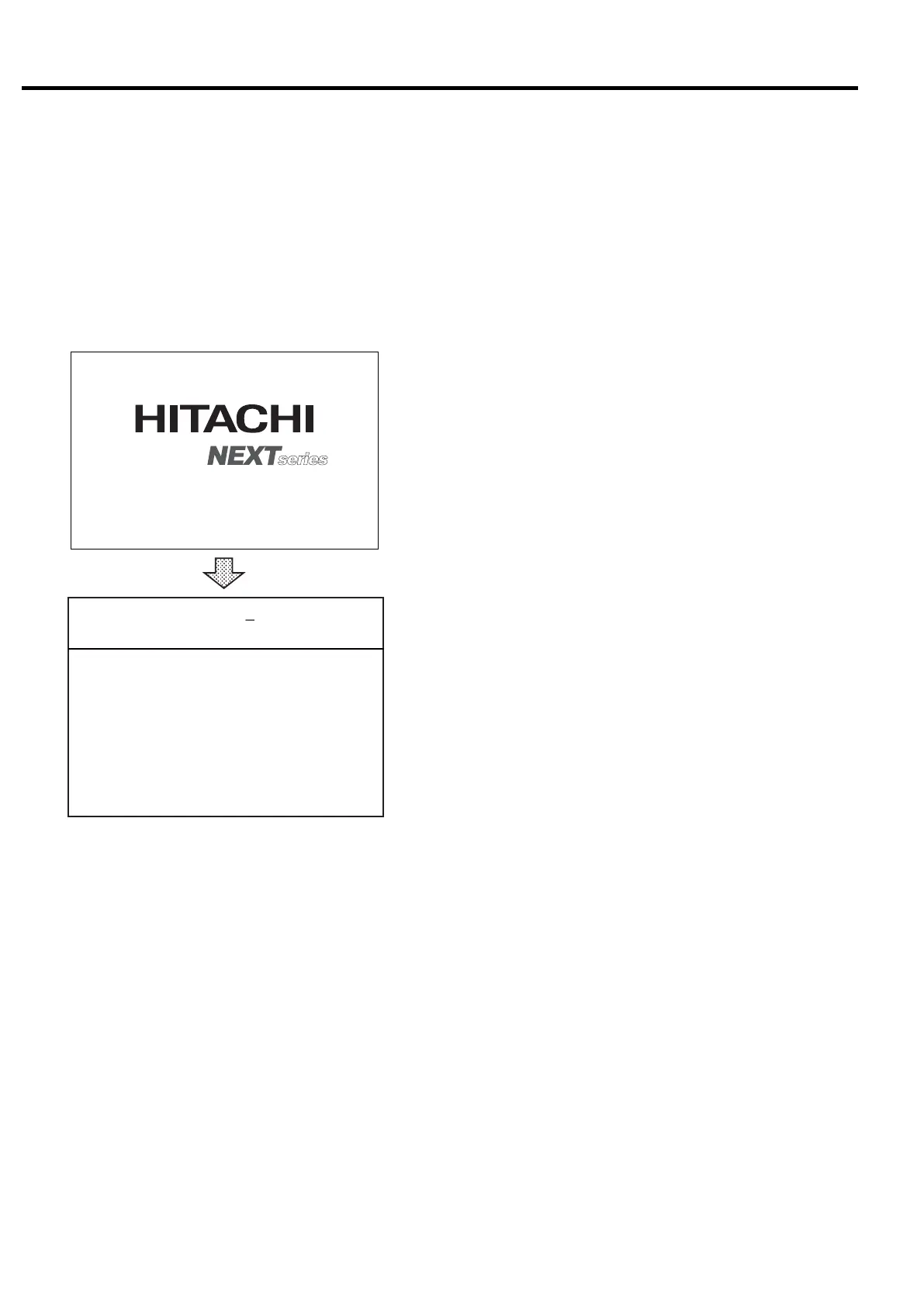

3.2.1 Connecting the Power

When you connect the power, the POWER light turns on

and the LCD monitor displays the following screen for 5

seconds, and then switches to the monitor screen (M1)

that displays control settings, discharge air pressure, and

total operating hours.

If phase is reversed, “Connection Error: Reverse

Phase” is displayed on the LCD monitor for setting and

connection inspection. In this case, switch 2 of the 3

main power cables.

If there is no phase, “Connection Error: No Phase” is

displayed on the LCD monitor. In this case, check the

power cables.

3.2 Start/Stop Operation

COMPRESSOR MONITOR

CONTROLLER

㻞㻜㻜㻥䠋㻜㻠䠋㻝㻟 㻝㻥䠖㻜㻞

㼀㼅㻼㻱 䠖㼂㻿㻰㻭

㻰 㻵 㻿䠊㻼㻾㻱㻿㻿 䠖 㻜䠊㻜 㻜 㼜 㼟 㼕

㻾㼁㻺 㻌㻴㻻㼁㻾䠖 㻝 㻞 㻜䡄

㻸㻻㻭㻰 㻌 㻴㻻㼁㻾 䠖 㻡 㻠䡄

㻸㻻㻭㻰 㼀 㻵 㻹㻱㻿䠖 㻝 㻞 㻟

㻸㻻㻭㻰 㻾㻭㼀㻱 䠖 㻝㻝䠂

㻸㻻㻭㻰 㼀 㻵 㻹㻱 䠖 㻞 㻠 䡏

㼁㻺㻸㻻㻭㻰 㻌 㼀 㻵 㻹㻱 䠖 㻝䡏

㻯㼁㻾㻾㻱㻺㼀䠖 㻡 㻜䠝

㻲㻾㻱㻽㼁㻱㻺㻯㼅 䠖 㻞 㻟 㻚 㻤䠤䡖

㻻㼁㼀㻼㼁㼀䠖 㻝㻜 㻚 㻡䡇䠳

*The asterisk flashes when the clock and total run-

ning hours are engaged.

5 sec

3.2.2 Start/Stop

When the START button is pressed the START light

turns on and the compressor starts operating. When run-

ning, the asterisk on the right side of running hours

flashes and running time is counted.

To stop, press the UNLOAD STOP button. Operation

stops when the air end and the air piping have dried for 5

minutes.

To stop the compressor immediately without unloading,

press the STOP button.

Note: If the STOP button is pressed while unloading, the

compressor stops immediately.

3.2.3 Emergency Stop

Pressing EMERGENCY STOP botton, the DSP com-

pressor immediately.

This switch should only be pressed in emergency.

The compressor can not be restarted until the switch is

manually reset. Turn the switch knob clockwise and

press the RESET button to reset.

12

3. OPERATING THE DSP [Start/Stop Operation]

Loading...

Loading...