5.4 Piping the DSP Air Compressor

5.4.1 General Instructions

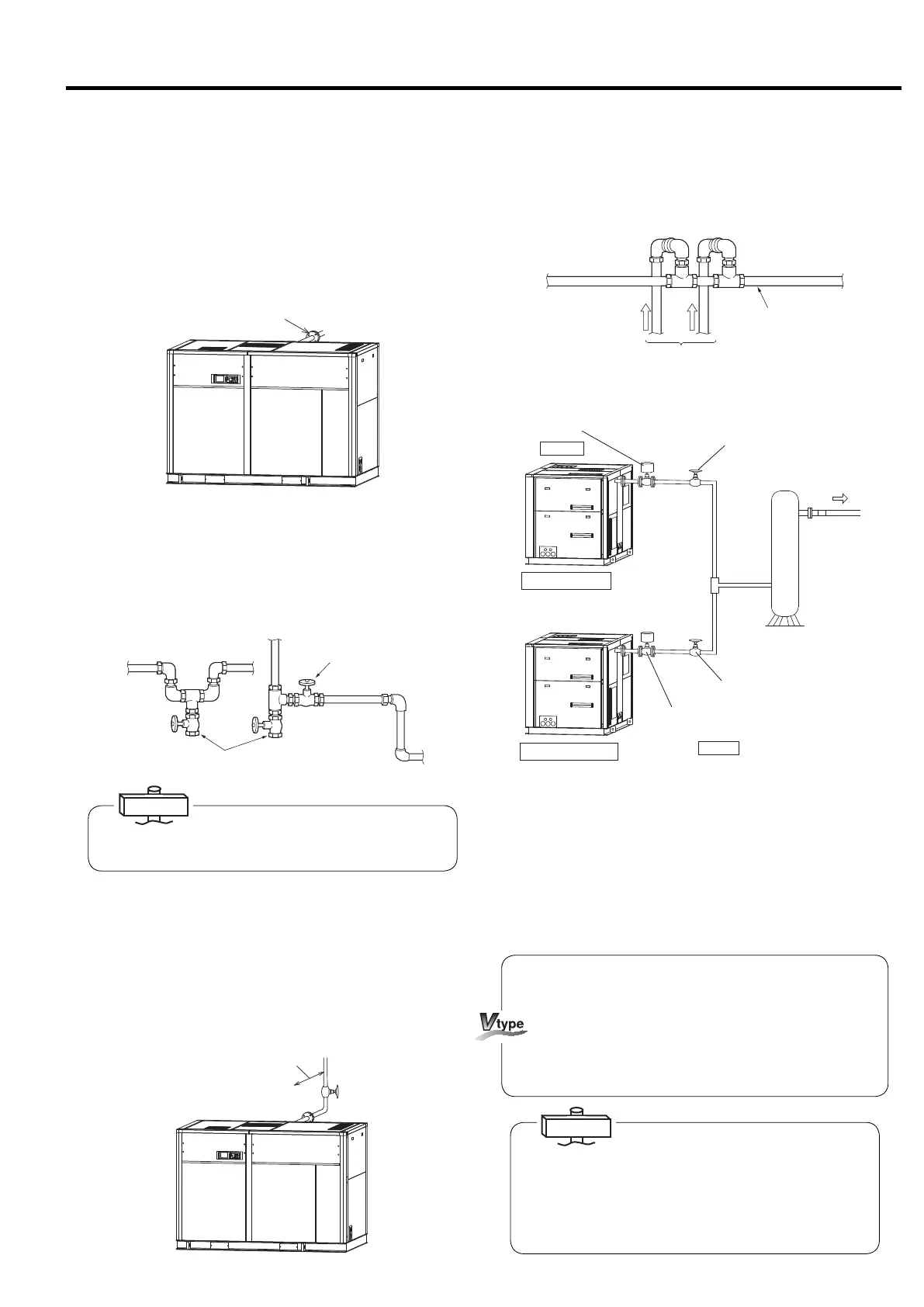

Stop Valve

Prevent the condensate from flowing back from the main

plant airline pipe.

⑦ If you connect the DSP’s discharge pipe to a main plant

airline pipe, run the discharge pipe upwards and then

downwards before joining to the main plant airline pipe,

to prevent the condensate from flowing back.

From the DSP

Main Plant

Airline Pipe

500mm or more

(50 inches)

① Use the degreased pipe as a plant airline pipe.

② If you connect the DSP directly to a gas pipe, use a

union or flange joint to ease disassembling the DSP

enclosure panels.

Flange Joint

③ If a plant airline pipe is longer, use a larger diameter

pipe taking into consideration the pressure loss

through the pipe.

④ If there is a concaved or upright part in a plant airline

pipe, provide a condensate drain valve at its bottom.

⑤ Install a discharge stop valve on a plant airline pipe

near the DSP.

⑥ If you want to elevate a plant airline pipe near the

DSP, keep a space of 500 mm (20 inches) between

the elevated pipe and the DSP enclosure panel to

ease the maintenance servicing.

39

5. INSTALLING AND PIPING THE DSP [Piping the DSP Air Compressor]

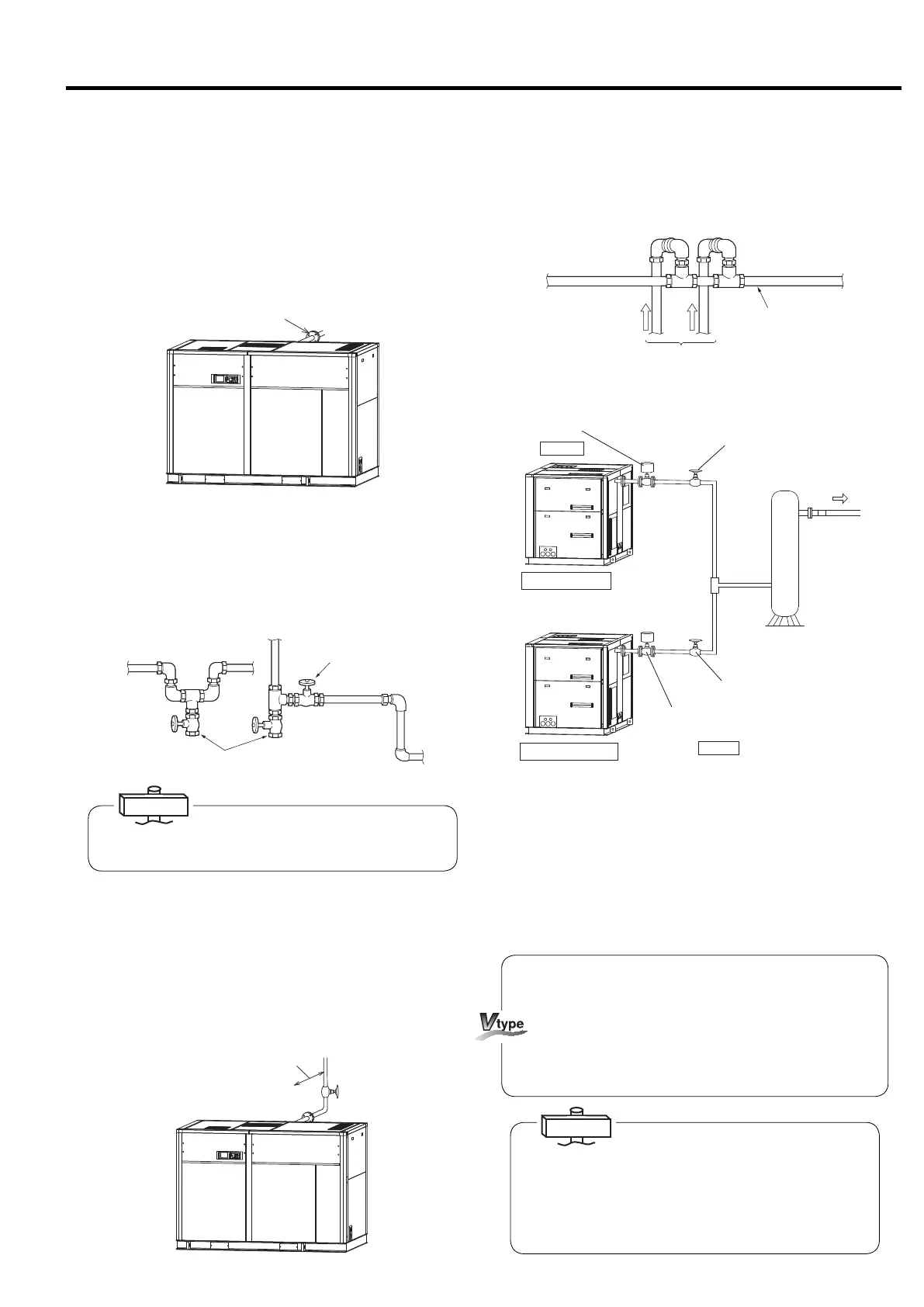

Stop Valve

Stop Valve

Discharge

Air

Opened

Closed

Air Receiver Tank

Operating DSP

Non-Operating DSP

Motorized isolation valve

(VSD only)

Motorized isolation valve

(VSD only)

If you operate only one of the two or more DSPs, keep

fully closed the discharge stop valve of the non-operating

DSP.

If you operate the two DSPs alternately and automatical-

ly, use an electric-driven or any other automatic stop

valve, one that can be automatically closed when the cor-

responding DSP has stopped.

If you use a solenoid valve as an automatic stop valve,

consult your Hitachi distributor.

A motorized isolation valve is included as a standard

accessory. Arrange for the motorized isolation valve

to be “closed” while the compressor is stopped.

If not using the motorized isolation valve, when oper-

ating one side, provide a stop valve for the discharge

piping of the compressor that is not running and close

it completely.

Assume that one DSP is operating and another is not. In

case that the discharge stop valve of the non-operating

DSP is opened, a back pressure is applied on that DSP ’s

aftercooler, check valve, etc. As a result the condensate is

produced much more than otherwise; even the Aftercooler

is rusted internally and the check valve is earlier rusted.

IMPORTANT

5.4.2 Two-Unit Parallel Piping / Operation

IMPORTANT

Loading...

Loading...