37

5. INSTALLING AND PIPING THE DSP

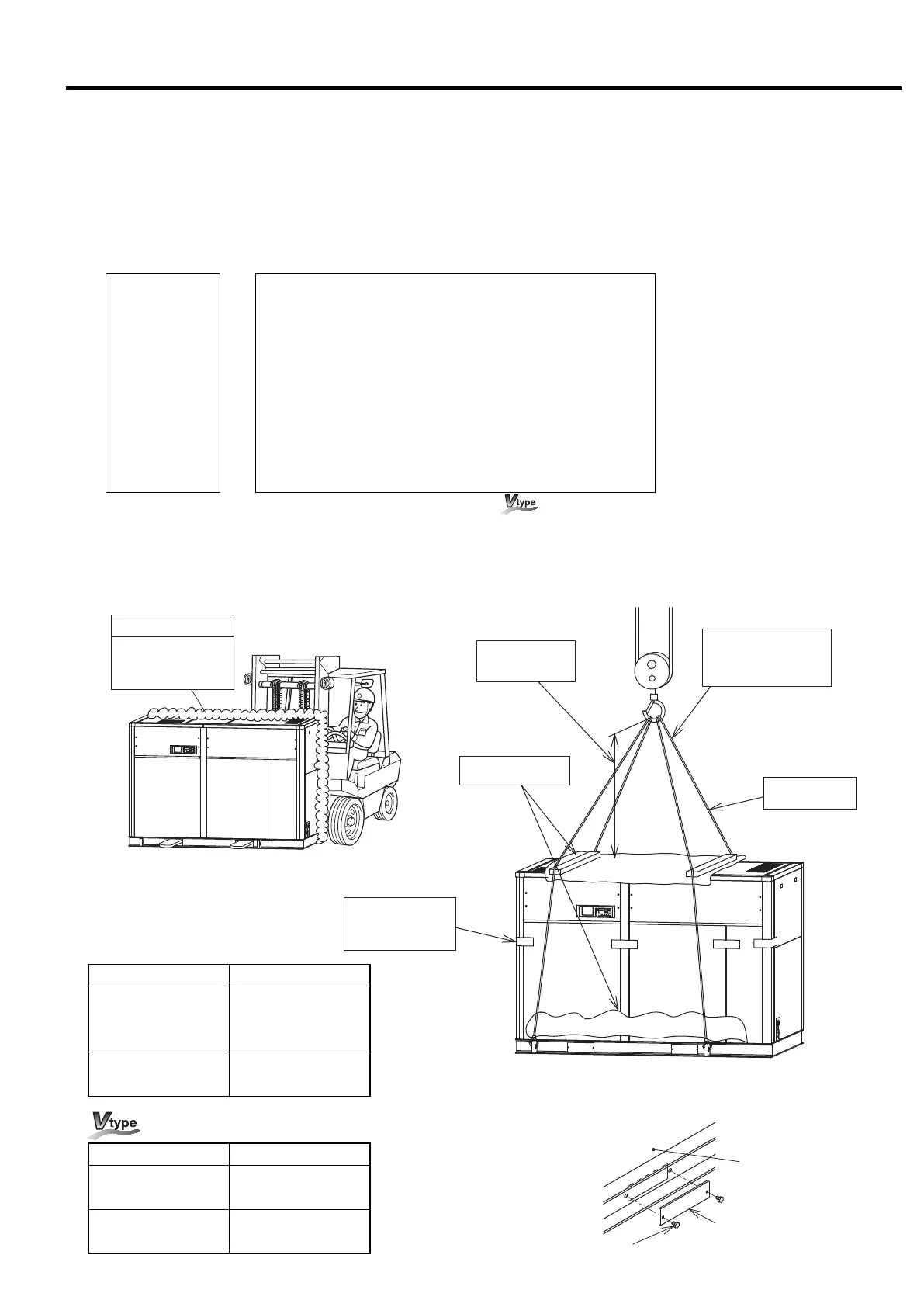

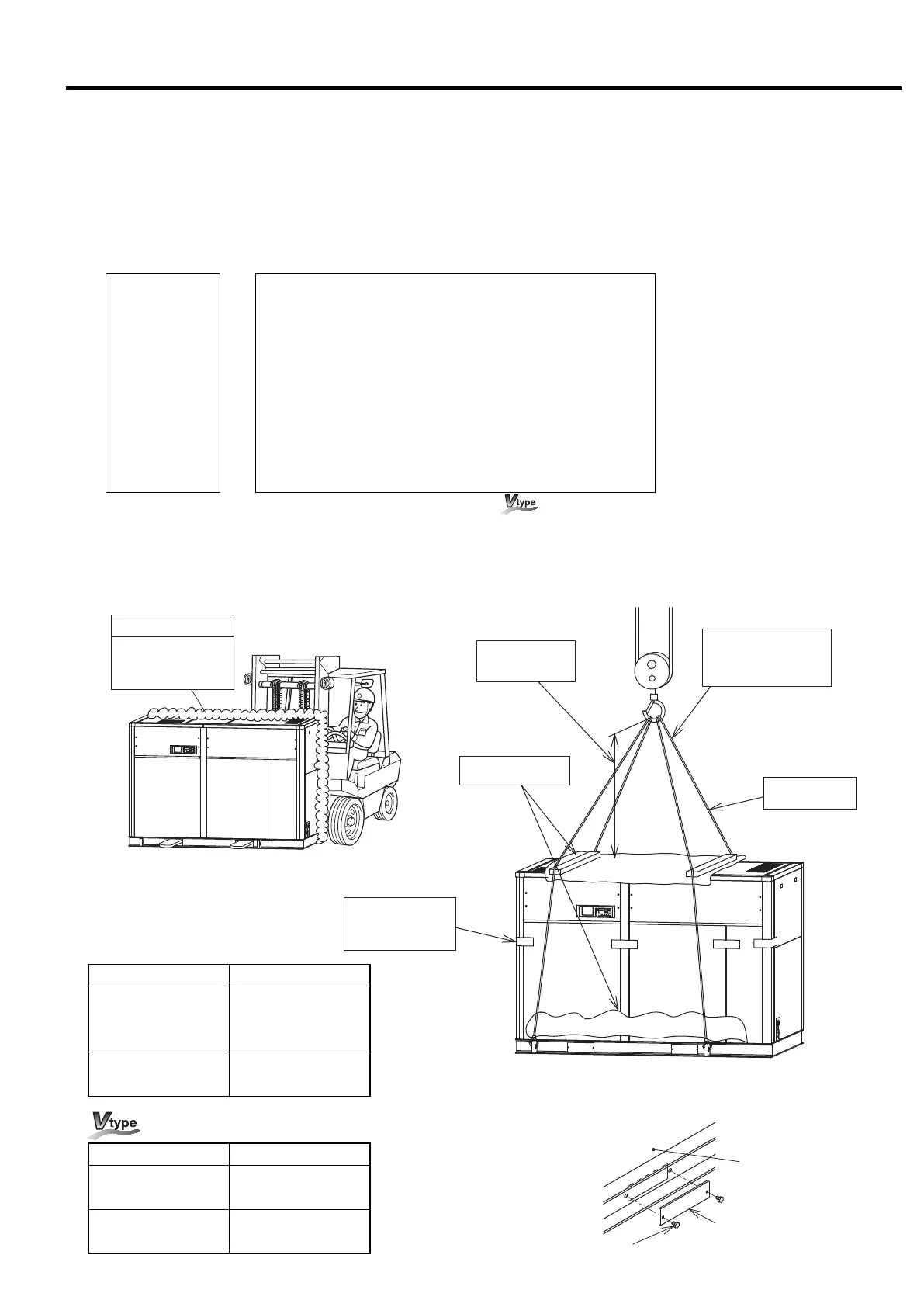

Common Base

Fork Slot Cover

Bolt (M6×15)

Pad

Use a pad to protect

the DSP enclosure

panels.

Use the adhesive tapes

to prevent the front door

from detached during

conveyance.

Use a pad to protect the

DSP enclosure panels.

Keep the distance of

1500 mm (60 inches)

or more.

Use the strong wires.

Adjust the wire length to

keep the DSP’s balance

when hoisting it.

Use the attached

tie frame.

5.1 Unpacking the DSP Air Compressor

■ After unpacking the crate, verify that the inside DSP is what you have ordered, by referring to page 81 through 82

“STANDARD SPECIFICATIONS and also by checking the model nameplate.

■ Verify that the DSP is not damaged or deformed in transportation.

Model Nameplate

Standard Accessories

Motor Output (kW)

Model

Frequency (Hz)

5.2 Conveying the DSP Air Compressor

■ With a Forklift ■With a Shop Crane

■ After installing the DSP, plug the fork slots with the fork

slot covers.

Model Total Mass

DSP-132WN

DSP-145WN

DSP-160WN

3,800 kg

(8,378 lb)

DSP-200WN

DSP-240WN

4,800 kg

(10,582 lb)

Foundation Bracket 4 pieces

Foundation Bolt/Nut (M24) 4 pieces

Bolt (M24) for Foundation Bracket 4 pieces

Fork Slot Cover 4 pieces

Bolt (M6) for Fork Slot Cover 8 pieces

R-NPT Nipple (1/4B) 2 pieces

R-NPT Nipple (3/8B) 2 pieces

R-NPT Nipple (1/2B) 2 pieces

R-NPT Nipple (3/4B) 3 pieces

Gasket 1 pieces

Handle 1 pieces

Motorized Isolation Valve(※) 1 piece

Motorized Water Isolation Valve(※) 1 piece

Model Total Mass (kg)

DSP-160VWN

4,000 kg

(8,819 lb)

DSP-240VWN

5,100 kg

(11,244 lb)

Item ※-marked shall be supplied only for

Loading...

Loading...