4.3 Troubleshooting the Oil Mist Remover

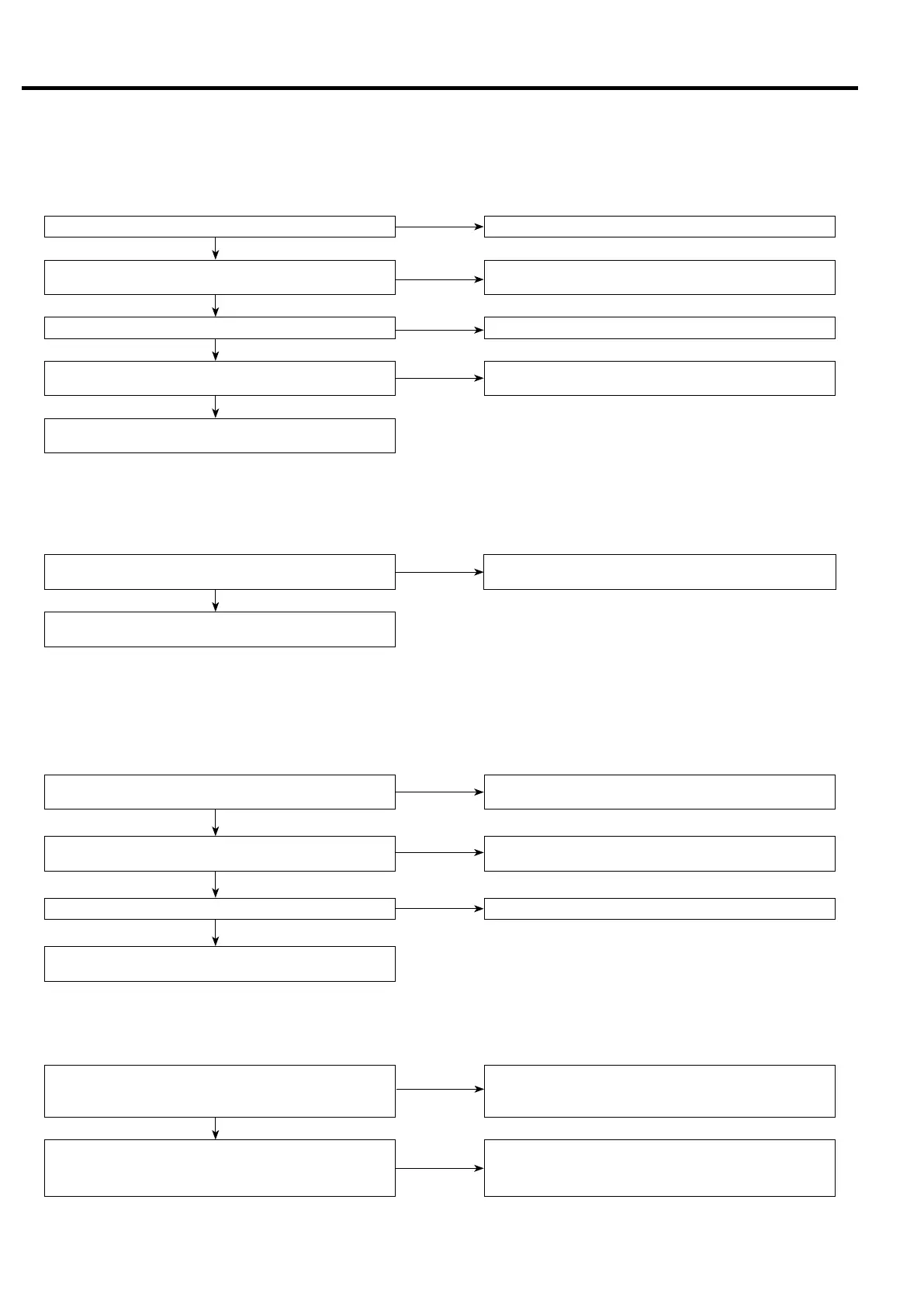

① The vacuum indicator shows a red mark (Gear case has a positive internal pressure)

② The safety relief valve has opened and oil mists are vented (the gear case internal pressure has risen).

See the NOTE below.

③ Oil is vented through the ejector’s compressed air outlet (the separated oil is not being recovered).

④ Oil pressure is low (oil pump may be inhaling air).

36

4. TROUBLESHOOTING [Troubleshooting the Oil Mist Remover]

The pressure gauges reads zero (0) MPa (psi). Check the solenoid valve for operation.

Pressure setting of the regulator is lower ?

Reset the regulator to a proper pressure.

Clean the fi lter.

Pressure of a control air is lower than 0.39 MPa (56 psi) ?

Maintain the pressure of a control air at 0.39 MPa (56 psi) or more.

The gear case or gear case vent pipe has a leak

(for example, the oil fi lling port plug on the gear case is not tight).

・ Tighten every screw and plug to remove all leaks.

・ Make sure that the safety relief valve is closed.

Element may be dirty.

Inspect the element and replace if necessary.

Yes

Yes

Yes

Yes

No

No

No

No

The safety relief valve is dirty or stuck open by a foreign

object.

Disassemble and clean the safety relief valve.

Replace if necessary.

Go to the procedure ①. The vacuum indicator shows a

red mark. (Gear case has a positive internal pressure.)

Yes

No

NOTE:

The safety relief valve opens immediately when starting the DSP (the control air pressure is still low) or when the DSP has

stopped. This is a normal occurrence.

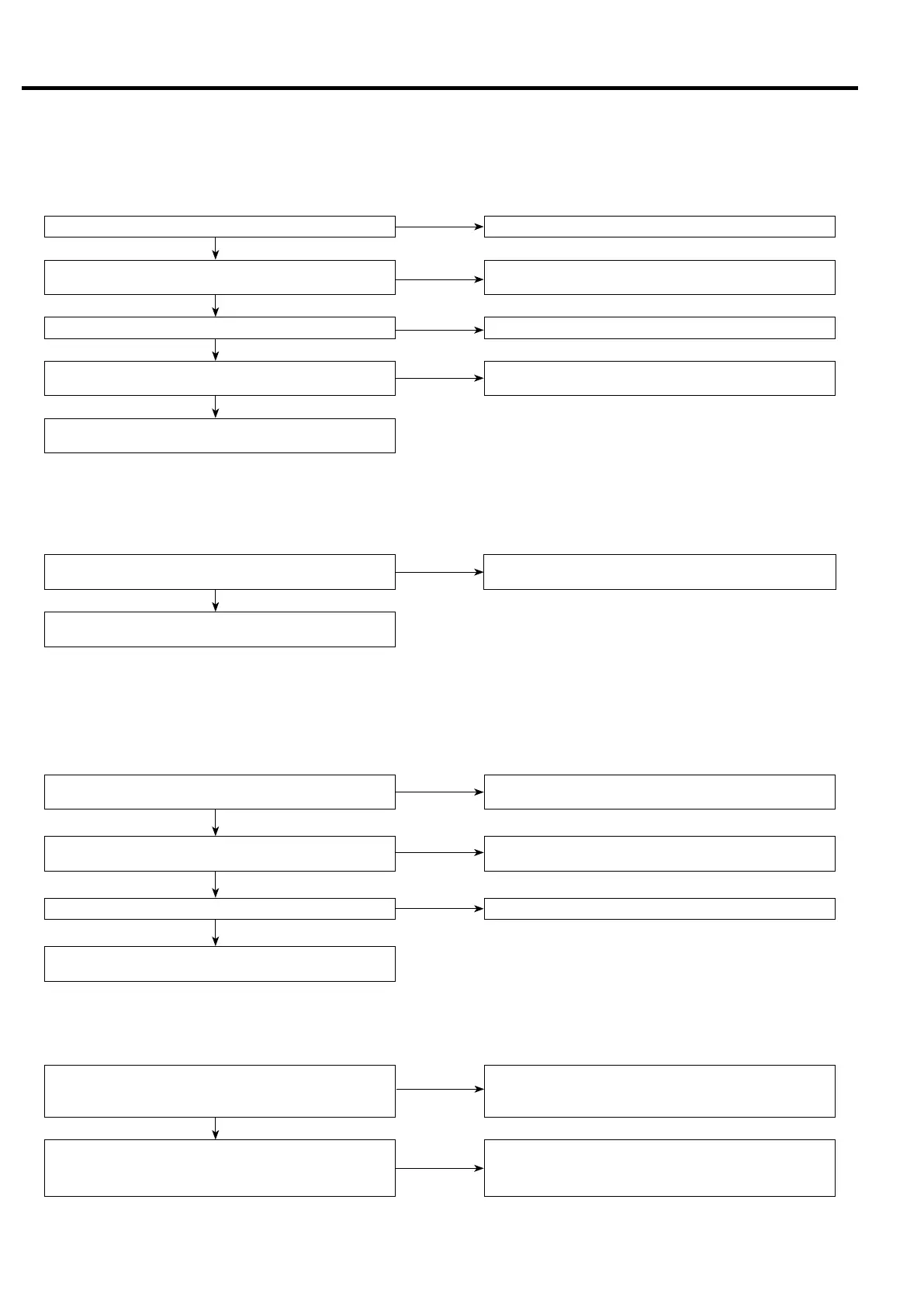

Accumulated oil is visible in the tube between the ele-

ment housing and the fl oat trap.

Clean the nozzle of the fl oat trap.

Upper or lower packing is not seated properly on the

element ?

Reinstall the element, seating the packing properly for a

maximum sealing performance.

Control air contains oil ? Check the control air for oil contents.

Element may be dirty.

Inspect the element and replace if necessary.

Yes

Yes

Yes

No

No

No

Has the air compressor developed an alarm or shutdown

trouble (i.e. oil fi lter dirty, oil pressure reduced due to oil

leaking, oil pump failed, safety relief valve failed, etc.)?

Readjust or repair as required.

The nozzle of the fl oat trap is clogged (for example, a

large quantity of air is inhaled through the oil recovery

pipe to the oil pump inlet)?

Clean the nozzle of the fl oat trap. Disassemble the fl oat

trap and clean.

Yes

Yes

No

NOTE:

The oil mist remover makes the gear case internal pressure negative during operation, reducing the pressure by 0.005 to 0.01

MPa (0.7 to 1.5 psi). This is not unusual; reset the oil pressure on the safety relief valve.

Loading...

Loading...